Tel: 0086-29 86063219

WhatsApp: 8617791389758

Address: 2-B, NO.8 Building North industrial park, Economic and Technological Development Zone, XI'AN city Shaanxi P.R.China

Email: hainaisen@hnsdrillbit.com

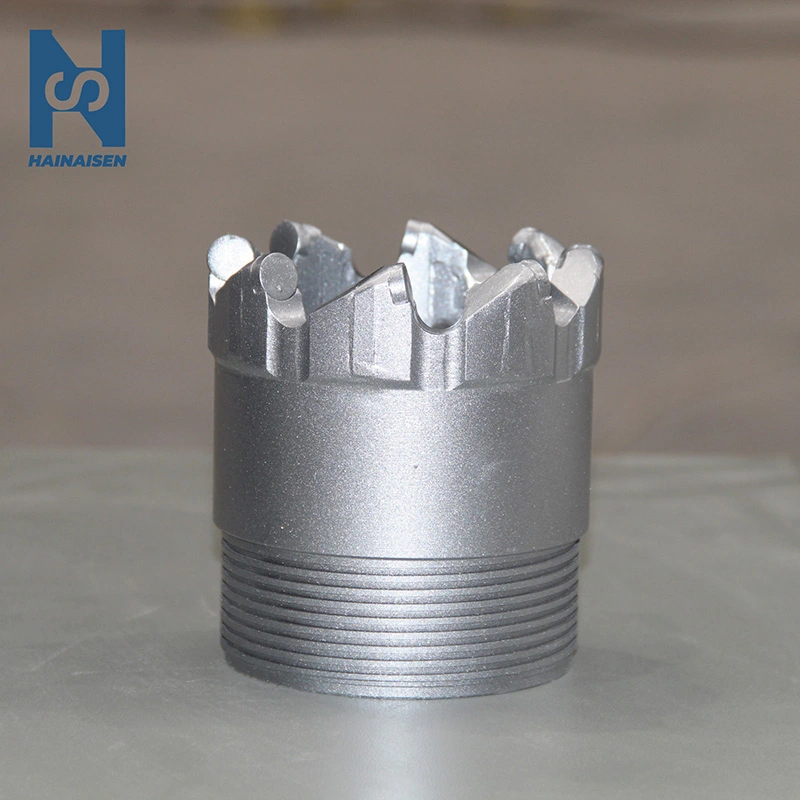

PDC Core Drill Bit With 8 Blades For Hole Drilling Used In Mining manufacturers

Powerful 8-Wing PDC Core Drill Bits

Shaanxi Hainaisen Petroleum Technology Co., Ltd. offers the 8-Wing PDC Core Drill Bit for Hole Drilling in Mining to tackle harsh mining environments.

As leading manufacturers of this drill bit, we combine innovative blade geometry with ultra-wear-resistant PDC cutters, achieving enhanced durability and faster penetration in hard rock formations.

The eight wings distribute load evenly, minimize vibration, and improve drilling stability and accuracy.

Each blade incorporates heat-treated high-grade tungsten carbide for superior impact resistance.

This bit is ideal for subsurface and high-stress mineral exploration scenarios.

Global mining teams trust Shaanxi Hainaisen’s manufacturing expertise in material selection and precision machining for this 8-wing PDC core drill bit.

With diameters ranging from 75mm to 300mm and compatibility with standard rigs, it suits diverse mining applications.

This is a reliable tool for rugged mining operations.

Shaanxi Hainaisen Petroleum Technology Co., Ltd.

Founded in 2013, Shaanxi Hainaisen Petroleum Technology Co., Ltd. specializes in high-performance diamond drill bits, PDC bits and professional drilling tools for energy and construction sectors.

Our global tailored solutions support oil & gas, coal mining and geotechnical projects, delivering consistent results worldwide.

Innovation & Precision Engineering

Our 3,500 m² facility boasts advanced 5-axis machining, CNC systems and automated welding for precision manufacturing. All tools are engineered for harsh conditions with uncompromising quality.

Customized Drilling Expertise

Supported by a dedicated R&D team, we design custom drill bits for unique geology, enhancing speed, stability and service life to solve on-site pain points.

Quality-Driven Strategic Partnerships

With over a decade of experience, our products meet strict industry standards, boosting efficiency, safety and reducing downtime.

We’ve built long-term partnerships with global energy firms, backed by tool reliability even in extreme conditions.

Partner with Hainaisen to turn geological challenges into project successes.

Powerful 8-Wing PDC Core Drill Bits for Mining

For tough mining operations, Shaanxi Hainaisen Petroleum Technology Co., Ltd. manufactures 8-wing PDC core drill bits. Precision-angled polycrystalline diamond compact (PDC) cutters penetrate rock 40% faster than standard bits.

Optimized Engineering for Hard Conditions

Even in abrasive environments, the 8-wing design balances load and minimizes wear. Diamond-edged blades cut coal, metal ores, and hard rock evenly.

Built-in hydraulic flow passages minimize heat during deep-hole drilling, stabilizing performance at depths over 1,500 meters.

Built to Last in Extreme Conditions

ISO-certified, these bits run 300 operational hours without blade replacement—three times longer than ordinary bits.

Shock-absorbing matrix alloy bodies and tungsten carbide inlays resist impact fractures.

Expert Precision Manufacturing

With over a decade of R&D, Shaanxi Hainaisen uses CNC-machined molds and automated sintering to ensure micron-level precision in mining drill bit production.

Blade spacing and cutter density can be adjusted for formations from light shale to quartzite.

Ideal for mineral extraction operations prioritizing drilling speed, durability, and minimal downtime.

FAQs

1. Why is the PDC Core Drill Bit With 8 Blades good for mining?

This drill bit is designed for severe mining conditions and high-performance drilling. Its 8-blade design makes quicker, cleaner cuts, and its ultra-hard PDC cutters withstand wear and heat. Trusted OEM SHAANXI HAINAISEN combines sophisticated materials and precision engineering to give exceptional endurance in abrasive rock formations.2. How does this drill bit increase drilling efficiency?

Key characteristics include optimized blade spacing for reduced vibration and smoother operation. Enhanced hydraulic design reduces downtime by clearing debris rapidly. Longer deep-hole drilling lifespan with reinforced matrix body. Leading manufacturers trust SHAANXI HAINAISEN to ensure each bit fulfills quality criteria for consistent output.3. Which industries use PDC core drill bits?

It may be utilized for geothermal drilling, construction, oil/gas activities, and mining and exploration. The adaptability and durability make it a trusted tool for professionals in tough conditions.4. What certifies these drill bits' quality?

SHAANXI HAINAISEN bits are ISO 9001 and API-compliant and tested for impact resistance and cutter retention. Every product is quality-checked to satisfy worldwide safety and performance standards.5. Why pick SHAANXI HAINAISEN for PDC drill bits?

They offer mining-specific creative engineering and cost-effective solutions with decades of experience. Their prompt customer service and track record of producing durable, high-performance tools make them a dependable project partner.

Best Selling Products

Related Blogs

Related Search

Tel: 0086-29 86063219

WhatsApp: 8617791389758

Address: 2-B, NO.8 Building North industrial park, Economic and Technological Development Zone, XI'AN city Shaanxi P.R.China

Email: hainaisen@hnsdrillbit.com