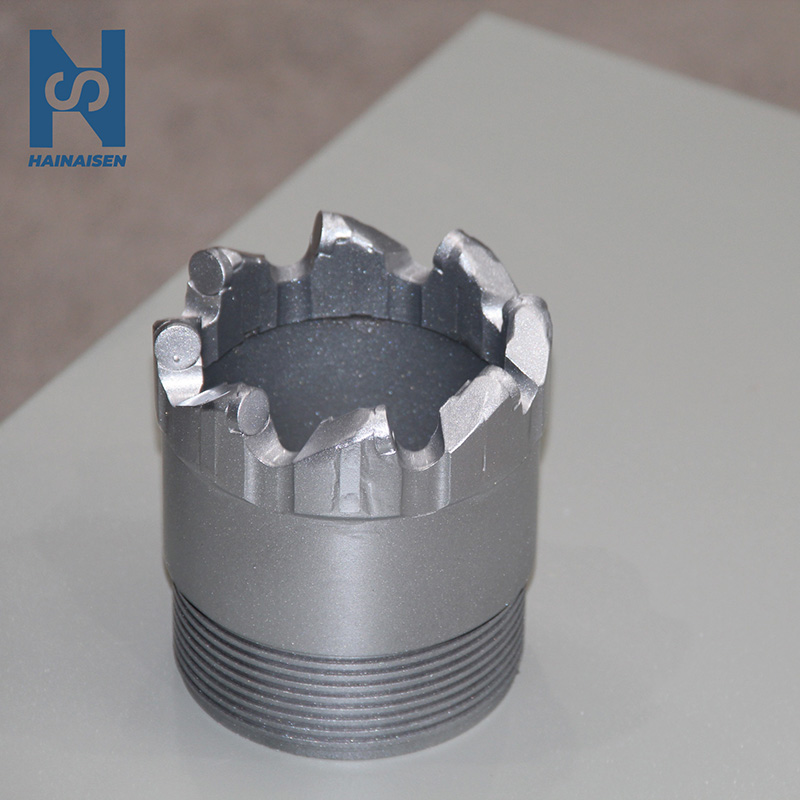

PDC Core Drill Bit Used For Drilling

Bit size: 94mm(75-173mm)

Number of Nozzle: 1

PDC cutter :1305

Connection type: connect 89 core tube(customized)

Package Details: customized

Applicable strata:1-12

Minimum Order Quantity : 10 pieces

Price : To be negotiable

Delivery Time : 5-7 business days

Payment Terms : T/T, L/C

- Product Description

PDC Core Drill Bit Used For Drilling: Engineered for Precision and Performance

SHAANXI HAINAISEN INTELLIGENT EQUIPMENT MANUFACTURING CO.,LTD is a leading manufacturer and supplier of PDC Core Drill Bit Used For Drilling. Our advanced manufacturing techniques and commitment to quality set us apart in the industry. With over a decade of experience, we provide innovative drilling solutions that enhance efficiency and reduce costs for our global clients.

Why Choose Our PDC Core Drill Bit Used For Drilling?

- Superior cutting efficiency for faster drilling rates

- Exceptional durability, reducing bit replacements

- Versatile design suitable for various formations

- Advanced cutter technology for improved wear resistance

- Customizable options to meet specific project requirements

- Competitive pricing without compromising on quality

- Backed by our expert technical support team

Application

Our PDC Core Drill Bit Used For Drilling excels in various industries:

- Oil and Gas Exploration:

- Offshore and onshore drilling operations

- Deep well projects requiring extended bit life

- Horizontal and directional drilling applications

- Mining and Mineral Exploration:

- Hard rock formations in precious metal mining

- Coal seam exploration and extraction

- Geothermal drilling projects

- Water Well Drilling:

- Municipal water supply projects

- Agricultural irrigation well drilling

- Groundwater exploration in challenging terrains

- Construction and Infrastructure:

- Foundation drilling for large structures

- Tunnel boring and excavation

- Soil sampling and geotechnical investigations

Customization Service

We understand that every drilling project has unique challenges. Our team of engineers works closely with clients to design custom product solutions. We consider factors such as formation hardness, depth, and specific operational requirements to create the perfect bit for your needs.

Material

Our PDC Core Drill Bits are crafted using premium-grade materials:

- High-quality steel body for durability

- Advanced polycrystalline diamond compact cutters

- Tungsten carbide matrix for enhanced wear resistance

Quality Control

At HAINAISEN, quality is our top priority. Every PDC Core Drill Bit undergoes rigorous testing:

- Strict raw material inspection

- Precision manufacturing processes

- Comprehensive performance testing

- Final quality checks before shipment

Why Choose HAINAISEN

- Industry-leading technology and innovation

- Experienced team with decades of expertise

- Commitment to customer satisfaction

- Competitive pricing and flexible solutions

- Robust after-sales support and service

Shipment Samples

We offer sample PDC Core Drill Bits for testing and evaluation. Contact us to discuss your specific requirements and arrange for a sample shipment.

Packaging and Transportation

Our bits are carefully packaged to ensure safe transportation:

- Custom-designed protective cases

- Shock-absorbing materials

- Clear labeling and handling instructions

- Flexible shipping options to meet your timeline

Transaction Feedback

We value customer feedback and continuously strive to improve our products and services. Your satisfaction is our measure of success.

After Sales Service

Our commitment doesn't end with the sale. We provide:

- Technical support and troubleshooting

- Performance optimization advice

- Warranty coverage on all products

- Rapid response to inquiries and concerns

Qualification Certification

HAINAISEN holds various industry certifications, demonstrating our commitment to quality and safety standards.

FAQ

Q: What is the average lifespan of your PDC Core Drill Bit?

A: The lifespan varies depending on the application, but our bits typically last 30-50% longer than traditional options.

Q: Can your bits be re-sharpened?

A: Yes, we offer re-sharpening services to extend the life of your PDC Core Drill Bit.

Q: Do you provide onsite technical support?

A: Absolutely, our team can provide onsite assistance for complex projects.

Q: What is your lead time for custom orders?

A: Custom orders typically take 2-4 weeks, depending on complexity and current production load.

Q: Are your PDC Core Drill Bits suitable for high-temperature environments?

A: Yes, we offer specialized bits designed for high-temperature drilling conditions.

Contact Us

Ready to elevate your drilling performance with our PDC Core Drill Bit Used For Drilling? Contact us at hainaisen@hnsdrillbit.com for expert advice and quotations.

VIEW MOREPDC Rock Drill Bit

VIEW MOREPDC Rock Drill Bit VIEW MORERock Roller Drill Bit

VIEW MORERock Roller Drill Bit VIEW MORE94mm PDC Flat Top Sintered Drill Bit

VIEW MORE94mm PDC Flat Top Sintered Drill Bit VIEW MOREThree Blade Concave Drill Bit Api For Manganese Coal Mines

VIEW MOREThree Blade Concave Drill Bit Api For Manganese Coal Mines VIEW MOREThree Blades Steel Body PDC Bit

VIEW MOREThree Blades Steel Body PDC Bit VIEW MORE3 Blades Steel Body PDC Bit

VIEW MORE3 Blades Steel Body PDC Bit VIEW MORECoal Mining Use Diamond Drill Bit

VIEW MORECoal Mining Use Diamond Drill Bit VIEW MORECoal Mines Use Haineisen PDC Drill Bits

VIEW MORECoal Mines Use Haineisen PDC Drill Bits