HAINAISEN Oil and Gas Drill Bits

High-performance PDC solutions for global drilling projects

Hainesun is a professional oil and gas drill bit manufacturer, supplier, and factory in China, specializing in the research and development and production of high-quality polycrystalline diamond composite (PDC) drill bits. For many years, we have been deeply involved in the oil drill bit manufacturing field, providing bulk customization services at highly competitive prices to meet the diverse needs of global oilfields, mining groups, and drilling contractors.

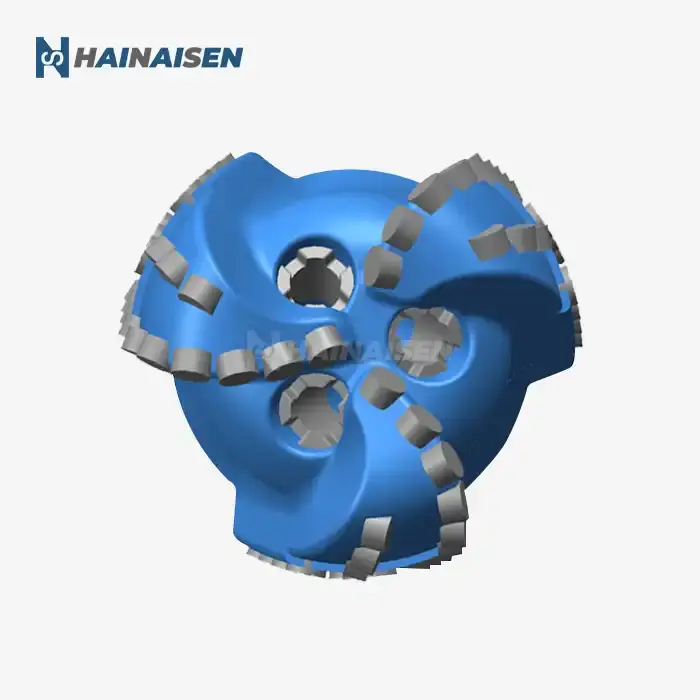

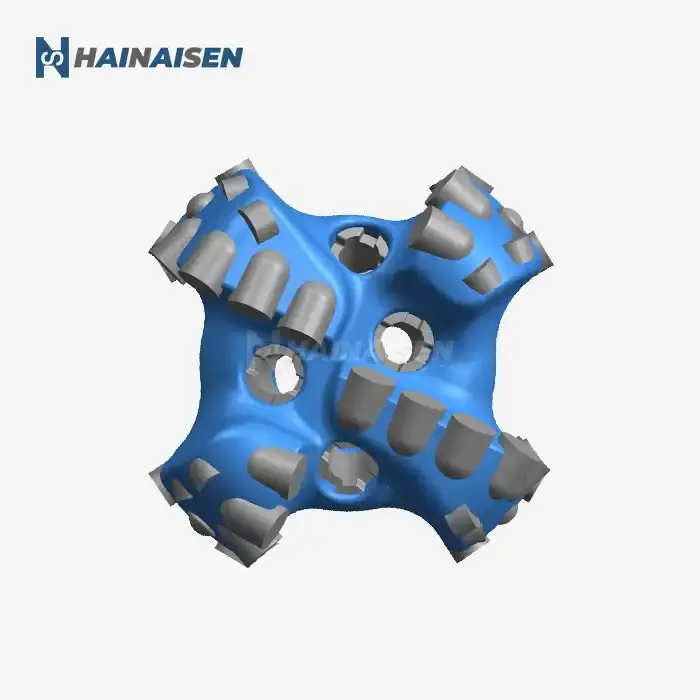

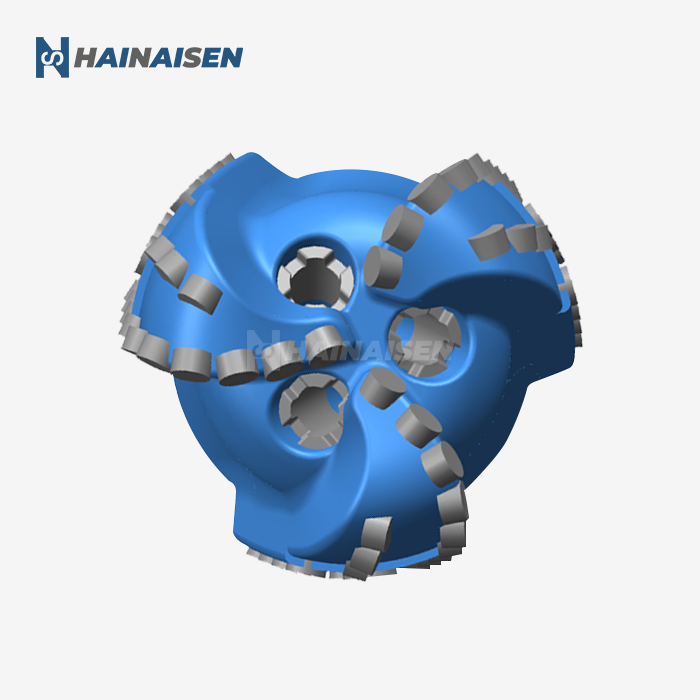

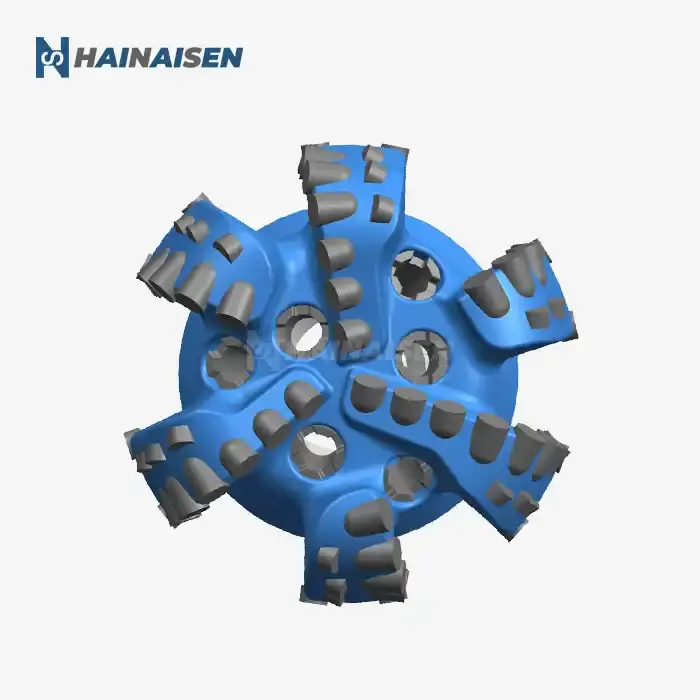

Our core product line covers 4- to 7-blade PDC drill bits, specifically designed for shale, sandstone, limestone, and complex interbedded formations. Whether operating in conventional, deep, or ultra-deep wells, Hainesun drill bits deliver consistent drilling speeds, extended service life, and significant cost savings.

Core product series

Core advantages and selling points

Ultra-hard Material + Wear-resistant Process, Extended Service Life

Utilizing imported high-quality base materials such as PDC (HV10000+), wear resistance is improved by 40%. It withstands temperatures up to 250℃ and pressures up to 150MPa, resulting in a service life 25-35% longer than the industry average, reducing tripping and lowering risks.

01

Optimized Cutting Design, Improved Drilling Efficiency

Based on CFD and finite element analysis, the cutting layout and hydraulic channels are optimized, increasing rock breaking efficiency by 30%+ and drilling speed by 20-40%. Strong cuttings carrying capacity prevents stuck drill bits and ensures continuous drilling.

02

Customized Solutions, Adapting to All Scenario Needs

Providing one-stop service including formation analysis, product customization, and technical support, covering all types of drill bits. Supporting small-batch customization and large-scale production, with urgent orders delivered within 7 working days.

03

Strict quality control to ensure operational safety

Full-process quality inspection, ISO9001 and API certified, each batch undergoes 12 rigorous tests with a 100% pass rate, effectively ensuring operational safety.

04

Application Examples

Client Needs: A 1500m horizontal section in a shale gas well, with the formation primarily composed of shale and containing a small amount of quartz sandstone. The requirements included increasing the mechanical drilling rate, extending bit life, and reducing tripping/running times.

Solution: Custom-designed PDC drill bits, optimized cutting tooth layout and hydraulic channels, and the use of high-strength PDC composite blades and reinforced cutter wing structure.

Implementation Results: A single drill bit completed 1480m of horizontal drilling, achieving a mechanical drilling rate of 8.5m/h, a 35% improvement over the original drill bit. Tripping/running times were reduced by 2, and the cost per well decreased by 22%. The client subsequently signed a long-term procurement agreement.

Customer Requirements: Well depth 7200m, bottom hole temperature 230℃, pressure 130MPa, formation mainly granite with compressive strength 120MPa, traditional drill bits suffer severe wear and low drilling efficiency;

Solution: Develop a diamond-reinforced special drill bit, using high-temperature stable diamond composite sheets, and optimize the drill bit crown shape and cutting angle;

Implementation Results: Drill bit lifespan reached 120 hours, 50% longer than traditional drill bits, mechanical drilling speed increased by 40%, successfully completing the ultra-deep well drilling task and receiving high praise from the customer.

FAQ

Q: How to choose a suitable oil and gas drill bit?

A: It requires a comprehensive judgment based on formation characteristics (lithology, compressive strength, porosity), drilling technology (vertical/horizontal/directional well), well depth, temperature, pressure, and other parameters. We offer free formation analysis and product selection services. Contact our engineering team for customized advice.

Q: What factors affect the lifespan of a drill bit?

A: It is mainly affected by formation hardness, drilling parameters (drilling pressure, rotation speed, displacement), drilling fluid properties, and operating procedures. We provide detailed drilling parameter optimization solutions to help customers extend drill bit lifespan.

Q: Do you provide after-sales service and technical support?

A: Yes. We provide 24-hour technical consultation, on-site installation guidance, drilling parameter optimization, troubleshooting, and other services. For quality problems within the product warranty period, free repair or replacement is available.

Q: What is the delivery cycle for customized drill bits?

A: The standard delivery time for customized products is 7-15 business days. Urgent orders can be expedited, with a minimum delivery time of 3-5 business days. Please consult with your account manager for specific details.

Qualifications and Certifications