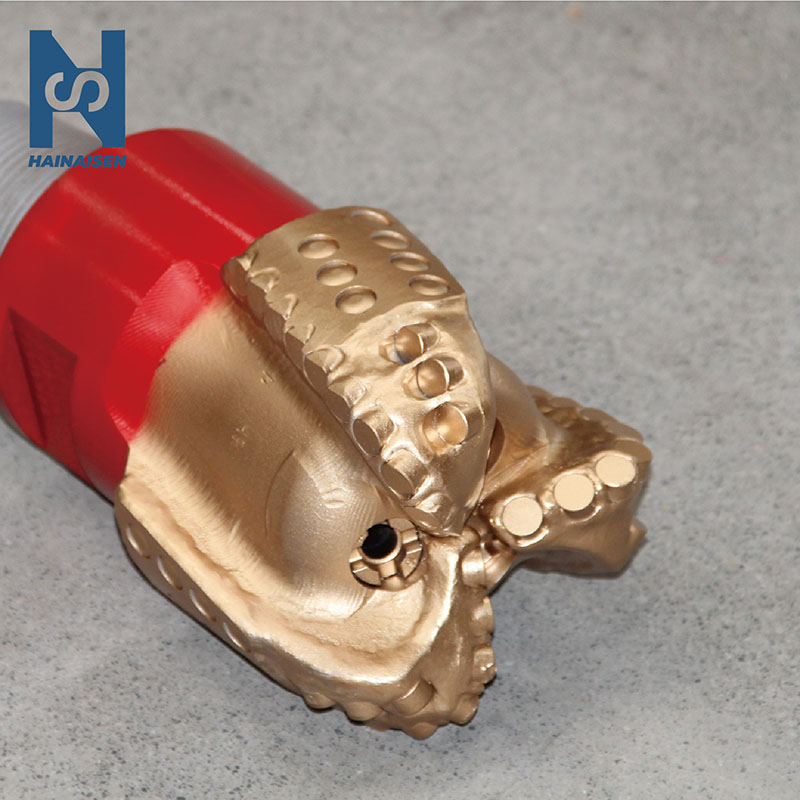

Three Blade Oil Drill Bit

Bit size:6”(152.4mm)

Number of blade: 3

Number of nozzle: 3

PDC cutter size:13mm

Total number of PDC cutters : 61

Height of bit:220mm

Gauge length: 65mm

API Connection: 3 -1/2 REG.PIN

Net weight: 22 KGS

- Product Description

Three Blade Oil Drill Bit: Precision Drilling Solution for Optimal Performance

SHAANXI HAINAISEN INTELLIGENT EQUIPMENT MANUFACTURING CO.,LTD is a leading manufacturer and supplier of high-quality products. Our innovative design and cutting-edge technology ensure superior performance in various drilling applications. With years of expertise, we deliver reliable and efficient Three Blade Oil Drill Bits that meet the demanding needs of the oil and gas industry.

Why Choose Our Three Blade Oil Drill Bit?

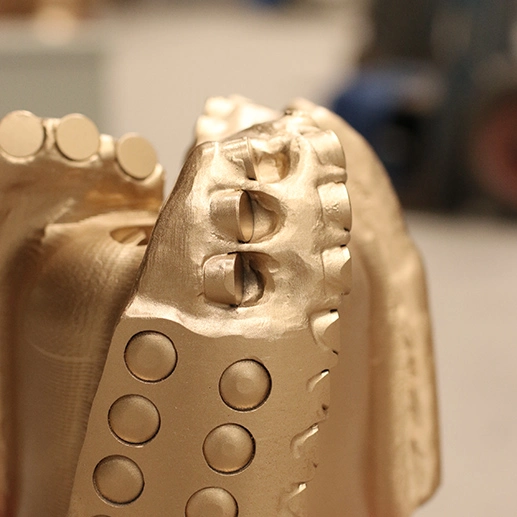

- Advanced blade design for faster penetration rates

- Improved stability and reduced vibration during drilling

- Enhanced durability for extended bit life

- Optimized hydraulics for efficient cuttings removal

- Customizable to meet specific formation requirements

Operating Parameters

| Parameter | Range |

|---|---|

| Speed (R/min) | 80-300 |

| Drilling Pressure (KN) | 10-100 |

| Flow Rate (LPS) | 20-35 |

| Applicable Strata | Medium hardness, low compressive strength (e.g., shale, limestone, sandstone, gypsum) |

Application

Our Three Blade Oil Drill Bit is ideal for:

- Oil and gas exploration and production

- Geothermal drilling operations

- Coal bed methane extraction

- Water well drilling

- Mineral exploration projects

These versatile bits excel in medium-hardness formations, offering optimal performance and cost-effectiveness. Their unique design ensures faster penetration rates and improved overall drilling efficiency.

Customization Service

We understand that every drilling project has unique requirements. Our team of experts works closely with clients to develop customized product solutions. We consider factors such as:

- Specific formation characteristics

- Desired drilling parameters

- Project budget constraints

- Environmental considerations

Our tailored approach ensures you get the perfect bit for your drilling needs.

Material

Our products are crafted using premium-grade materials, including:

- High-strength steel body

- Polycrystalline Diamond Compact (PDC) cutters

- Tungsten carbide matrix

These materials guarantee exceptional durability and wear resistance, even in challenging drilling conditions.

Quality Control

At HAINAISEN, we uphold rigorous quality control protocols at every stage of the manufacturing process. From material selection to final assembly, our drill bits are subjected to thorough testing that adheres to both industry standards and our own stringent specifications. This meticulous approach ensures each product delivers reliable performance, durability, and safety, providing our clients with the confidence that our bits are built to excel in even the most demanding drilling environments.

Why Choose HAINAISEN

- Over a decade of industry experience

- State-of-the-art manufacturing facilities

- Continuous innovation and R&D

- Exceptional customer support

- Competitive pricing

Shipment Samples

We offer sample products for evaluation. Contact us to request a sample and experience the HAINAISEN difference firsthand.

Packaging and Transportation

Our bits are carefully packaged to prevent damage during shipping. We offer various transportation options to meet your delivery requirements.

Transaction Feedback

We value customer feedback and continuously strive to improve our products and services based on your input.

After-Sales Service

Our commitment doesn't end with the sale. We provide comprehensive after-sales support, including:

- Technical assistance

- Maintenance guidance

- Performance optimization recommendations

Qualification Certification

HAINAISEN holds relevant industry certifications, ensuring our products meet the highest quality and safety standards.

FAQ

Q: What is the average lifespan of a product?

A: The lifespan varies depending on formation and operating conditions but typically ranges from 100 to 300 hours of drilling time.

Q: Can these bits be re-sharpened?

A: Yes, our bits can be re-sharpened to extend their usable life, providing cost savings for our clients.

Q: How do Three Blade Oil Drill Bits compare to other bit designs?

A: Three blade bits offer a balance of stability, penetration rate, and durability, making them versatile for various formations.

Q: What's the typical delivery time for custom orders?

A: Custom orders usually take 2-4 weeks, depending on specifications and complexity.

Q: Do you offer training on proper bit selection and operation?

A: Yes, we provide comprehensive training to ensure optimal bit performance and longevity.

Contact Us

For inquiries or to place an order, please contact us at hainaisen@hnsdrillbit.com.

VIEW MOREFour Blade Wing High Performance Petroleum Drill Bit

VIEW MOREFour Blade Wing High Performance Petroleum Drill Bit VIEW MOREOil Diamond Drill Bit

VIEW MOREOil Diamond Drill Bit VIEW MOREDiamond Drill Bits For Oil Rigs

VIEW MOREDiamond Drill Bits For Oil Rigs VIEW MOREPetroleum Drilling Equipment PDC

VIEW MOREPetroleum Drilling Equipment PDC VIEW MOREHigh Quality PDC Drill Bits

VIEW MOREHigh Quality PDC Drill Bits VIEW MOREAlloy Scraper Drill Bit For Water Well

VIEW MOREAlloy Scraper Drill Bit For Water Well VIEW MORECoal Mine Drilling Opening And Closing Drill Bit

VIEW MORECoal Mine Drilling Opening And Closing Drill Bit VIEW MOREDiamond Drill Bit Oil Rig

VIEW MOREDiamond Drill Bit Oil Rig