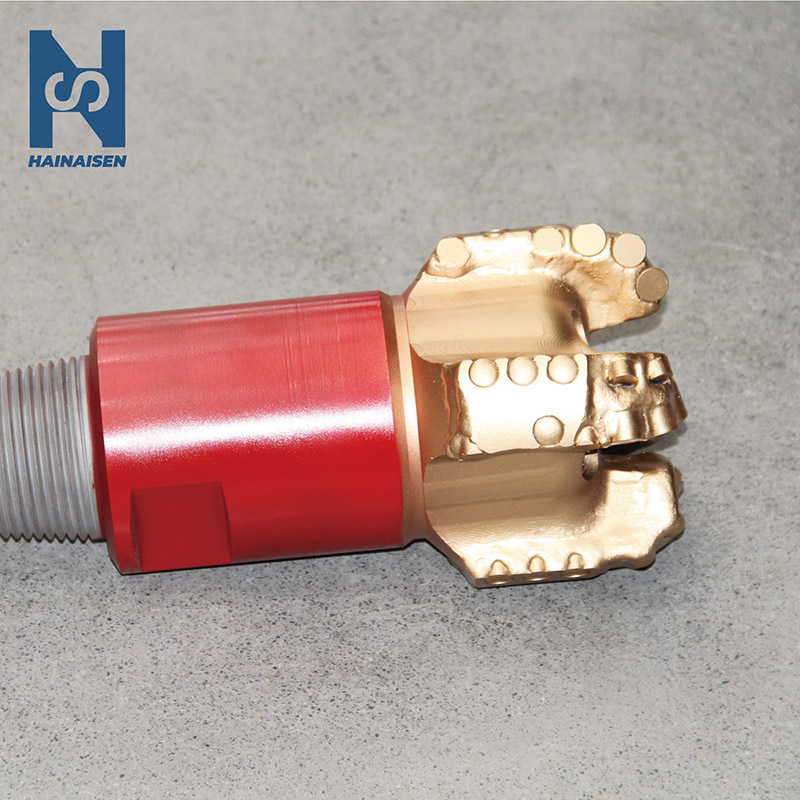

Four Blade Wing High Performance Petroleum Drill Bit

Bit size:8.5”(215.9mm)

Number of blade: 4

Number of nozzle: 6

PDC cutter size:13mm/16mm

Total number of PDC cutters : 57

Height of bit:280mm

Gauge length: 62mm

API Connection: 4 -1/2 REG.PIN

Net weight: 45KGS

- Product Description

Four Blade Wing High Performance Petroleum Drill Bit: Revolutionizing Drilling Efficiency

SHAANXI HAINAISEN INTELLIGENT EQUIPMENT MANUFACTURING CO.,LTD is a leading manufacturer and supplier of Four Blade Wing High Performance Petroleum Drill Bits. Our innovative design and advanced manufacturing processes set us apart in the industry. With over a decade of experience, we deliver superior drilling solutions for oil, gas, and mining operations worldwide.

Why Choose Our Four Blade Wing High Performance Petroleum Drill Bit?

- Exceptional durability and wear resistance

- Improved rate of penetration (ROP)

- Enhanced stability in various formations

- Optimized hydraulics for efficient cuttings removal

- Reduced vibration for smoother drilling operations

- Cost-effective solution for medium hardness strata

Operating Parameters:

| Parameter | Range |

|---|---|

| Speed (R/min) | 60-250 |

| Drilling Pressure (KN) | 10-100 |

| Flow Rate (LPS) | 25-36 |

| Applicable Strata | Medium hardness, low compressive strength (e.g., shale, limestone, sandstone, gypsum) |

Applications:

- Oil and gas exploration and production

- Geothermal drilling projects

- Coal bed methane extraction

- Water well drilling

- Mining operations in medium hardness formations

- Horizontal and directional drilling applications

Customization Service:

We understand that every drilling project is unique. Our team of experts works closely with clients to design and manufacture Four Blade Wing High Performance Petroleum Drill Bits tailored to specific geological conditions and operational requirements. From bit profile adjustments to cutter material selection, we ensure optimal performance for your drilling challenges.

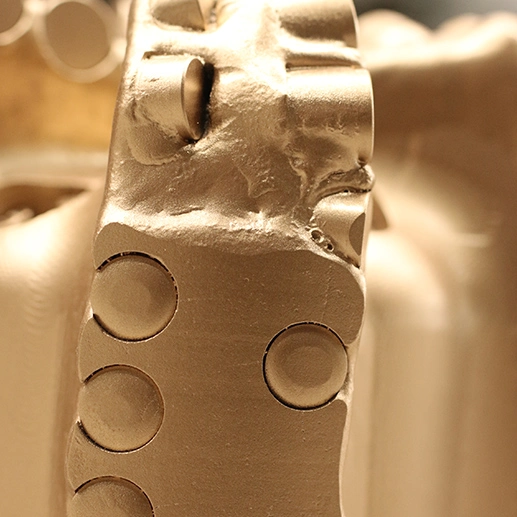

Material:

Our products are crafted using premium-grade steel bodies and high-quality PDC (Polycrystalline Diamond Compact) cutters. This combination ensures exceptional durability and cutting efficiency in demanding drilling environments.

Quality Control:

At HAINAISEN, quality is our top priority. Each product undergoes rigorous testing and inspection throughout the manufacturing process. Our ISO 9001:2015 certified quality management system guarantees consistent excellence in every product we deliver.

Why Choose HAINAISEN:

- Industry-leading R&D capabilities

- State-of-the-art manufacturing facilities

- Experienced technical support team

- Competitive pricing and flexible payment terms

- Proven track record of successful global projects

Shipment Samples:

We provide sample products specifically for evaluation, enabling you to assess their performance, quality, and suitability for your needs. Our dedicated sales team is ready to collaborate with you to understand your unique requirements and guide you through the process of obtaining samples. Simply reach out to us to discuss details, and we will efficiently arrange sample shipments tailored to your timeline, ensuring a smooth and informative experience to help you make confident decisions about our offerings.

Packaging and Transportation:

Our drill bits are securely packaged in sturdy wooden crates to ensure safe transportation. We work with reliable logistics partners to deliver your order efficiently, anywhere in the world.

Transaction Feedback:

We value customer satisfaction and continuously improve our products based on user feedback. Our dedicated support team is always ready to address any concerns or questions you may have about our products.

After-Sales Service:

HAINAISEN provides comprehensive after-sales support, including:

- Technical consultation

- On-site training

- Performance optimization recommendations

- Prompt resolution of any product-related issues

Qualification Certification:

Our products meet international industry standards and are certified by relevant authorities. We hold ISO 9001:2015, API, and CE certifications, ensuring the highest quality and safety standards.

FAQ:

Q: What is the average lifespan of your product?

A: The lifespan varies depending on formation and operating conditions, but typically ranges from 100 to 300 hours of drilling time.

Q: Can these drill bits be used in hard rock formations?

A: While designed for medium hardness formations, our bits can handle some harder formations. Contact us for specific recommendations.

Q: Do you offer technical support for bit selection?

A: Yes, our experienced engineers provide comprehensive support in selecting the right bit for your project.

Q: What is the lead time for custom orders?

A: Custom orders usually take 2-4 weeks, depending on complexity and current production schedules.

Q: Are your drill bits repairable?

A: In some cases, minor repairs can be performed. Our team can assess and advise on repair options.

Contact Us:

For inquiries about our Four Blade Wing High Performance Petroleum Drill Bits or any other products, please email us at hainaisen@hnsdrillbit.com.