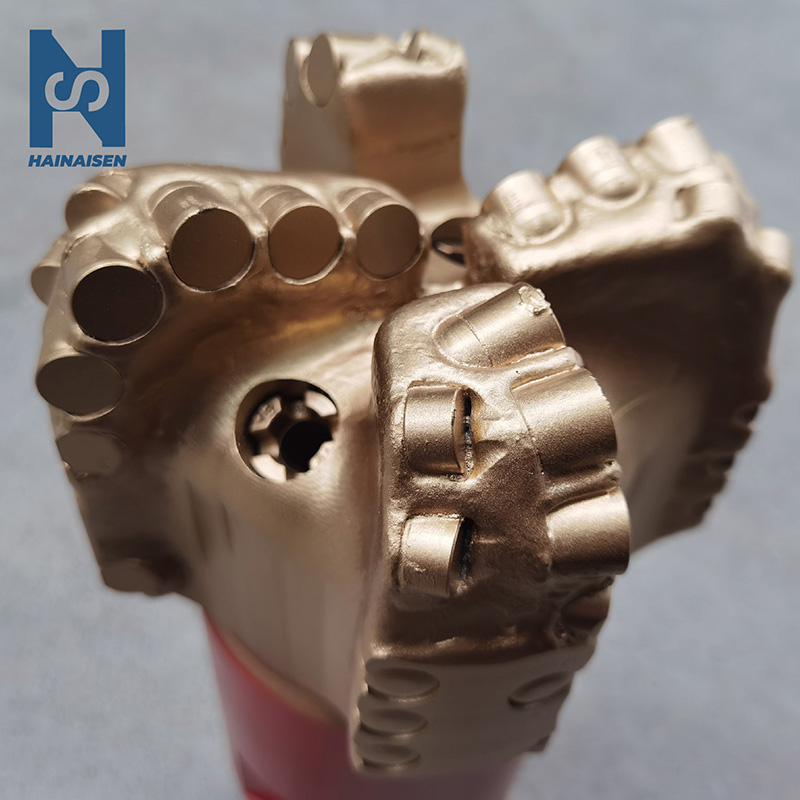

Four Blade Wing Petroleum Drill Bit

Bit size:8.5”(215.9mm)

Number of blade: 4

Number of nozzle: 6

PDC cutter size:13mm/16mm

Total number of PDC cutters : 57

Height of bit:280mm

Gauge length: 62mm

API Connection: 4 -1/2 REG.PIN

Net weight: 45KGS

- Product Description

Four Blade Wing Petroleum Drill Bit: Advanced Drilling Solution for Oil & Gas Industry

SHAANXI HAINAISEN INTELLIGENT EQUIPMENT MANUFACTURING CO.,LTD is a leading Four Blade Wing Petroleum Drill Bit manufacturer and supplier. Our advanced product offers superior performance and durability for oil and gas drilling operations. With over a decade of experience, we've developed cutting-edge technology to meet the demanding needs of the energy sector.

Why Choose Our Four Blade Wing Petroleum Drill Bit?

- High-performance design for efficient drilling

- Durable construction for extended bit life

- Optimized cutting structure for various formations

- Improved rate of penetration (ROP)

- Reduced vibration for smoother operation

- Cost-effective solution for drilling projects

Operating Parameters

| Parameter | Range |

|---|---|

| Speed (R/min) | 60-250 |

| Drilling Pressure (KN) | 10-100 |

| Flow Rate (LPS) | 25-36 |

| Applicable Strata | Medium hardness, low compressive strength (e.g., shale, limestone, sandstone, gypsum) |

Applications

Our Four Blade Wing Petroleum Drill Bit is ideal for:

- Oil and gas exploration and production

- Geothermal drilling projects

- Coal bed methane extraction

- Water well drilling

- Mining operations

These versatile bits excel in medium-hardness formations with low compressive strength. They're particularly effective in shale, limestone, sandstone, and gypsum strata, making them a go-to choice for many drilling operations.

Customization Services

We understand that every drilling project is unique. That's why we offer customization services for our product. Our team of experts can tailor the bit design to your specific needs, considering factors such as:

- Formation characteristics

- Well depth and diameter

- Drilling fluid properties

- Specific performance requirements

Contact us to discuss your custom product needs.

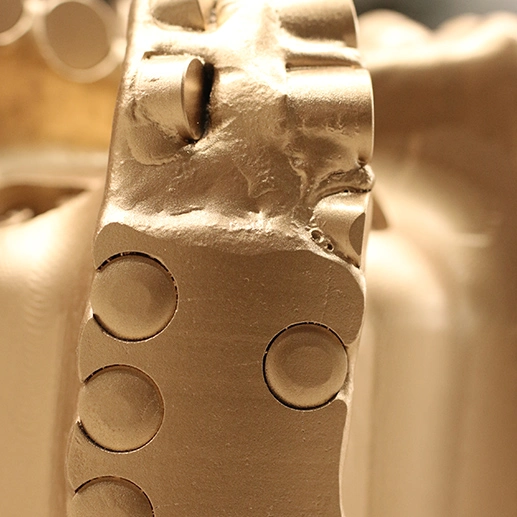

Material

Our bits are crafted using premium-grade materials, including:

- High-strength steel body

- Advanced PDC cutters

- Wear-resistant matrix materials

These quality components ensure longevity and consistent performance in challenging drilling environments.

Quality Control

At HAINAISEN, we maintain strict quality control measures:

- Rigorous testing at every production stage

- Adherence to international industry standards

- Regular equipment calibration and maintenance

- Continuous improvement of manufacturing processes

Why Choose HAINAISEN

- Over 10 years of industry experience

- State-of-the-art manufacturing facility

- Dedicated R&D team for continuous innovation

- Comprehensive after-sales support

- Competitive pricing without compromising quality

Shipment Samples

We are pleased to offer sample products designed for thorough evaluation, allowing you to assess their suitability for your unique applications. Whether for testing, prototyping, or compatibility checks, our samples provide valuable insights into performance and quality. Reach out to our team today to discuss your specific requirements and gain detailed guidance on obtaining samples tailored to your needs. We’re committed to ensuring a seamless process that helps you make informed decisions about integrating our products into your projects.

Packaging and Transportation

Our bits are carefully packaged to ensure safe transportation:

- Robust wooden crates or metal boxes

- Custom foam inserts for added protection

- Clear labeling and handling instructions

- Flexible shipping options to meet your needs

Transaction Feedback

We value customer satisfaction and continuously seek feedback to improve our products and services. Many clients praise our product for its reliability and performance in the field.

After-Sales Service

Our commitment doesn't end with the sale. We provide comprehensive after-sales support, including:

- Technical consultation

- Performance analysis

- Troubleshooting assistance

- Warranty coverage

Qualification Certification

HAINAISEN holds various industry certifications, demonstrating our commitment to quality and safety standards in the manufacture of products.

FAQ

Q: What is the average lifespan of a product?

A: The lifespan varies depending on operating conditions, but our bits typically last 20-30% longer than standard options.

Q: Can these bits be used in high-temperature environments?

A: Yes, our products are designed to withstand high-temperature drilling conditions.

Q: Do you offer training on proper bit usage?

A: Absolutely. We provide comprehensive training and support to ensure optimal bit performance.

Q: What's your typical lead time for custom orders?

A: Custom product orders usually take 4-6 weeks, depending on specifications.

Q: Are your bits suitable for horizontal drilling?

A: Yes, our products are engineered for both vertical and horizontal drilling applications.

Contact Us

For more information about our Four Blade Wing Petroleum Drill Bit or to place an order, please contact us at postmaster@hnsdrillbit.com.

VIEW MOREApi Polycrystalline Diamond Drill Bit

VIEW MOREApi Polycrystalline Diamond Drill Bit VIEW MOREThree Blade Concave Drill Bit Api For Manganese Coal Mines

VIEW MOREThree Blade Concave Drill Bit Api For Manganese Coal Mines VIEW MORE6-Blade PDC Drill Bit

VIEW MORE6-Blade PDC Drill Bit VIEW MOREFive Blades PDC Drill Bits

VIEW MOREFive Blades PDC Drill Bits VIEW MOREDrill Bits For Oil Drilling

VIEW MOREDrill Bits For Oil Drilling VIEW MOREFive Blade Oil Drill Bit

VIEW MOREFive Blade Oil Drill Bit VIEW MORE4 Wings Blades PDC Bit

VIEW MORE4 Wings Blades PDC Bit VIEW MOREFour Blade Wing High Performance Petroleum Drill Bit

VIEW MOREFour Blade Wing High Performance Petroleum Drill Bit