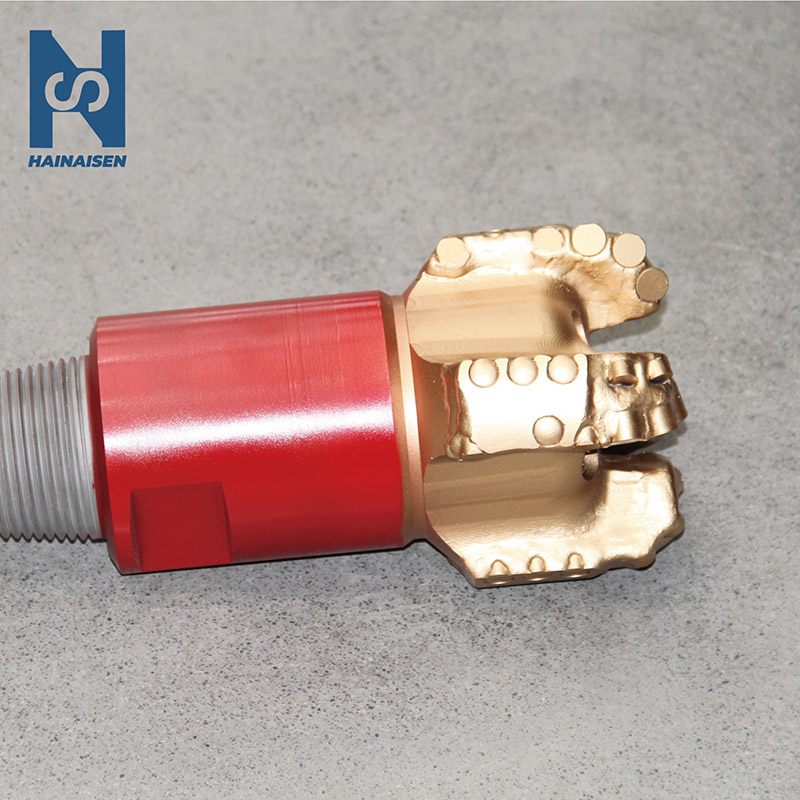

Petroleum Drilling Equipment PDC

Bit size:6.5”(165.1mm)

Number of blade: 4

Number of nozzle: 4

PDC cutter size:13mm/16mm

Total number of PDC cutters : 50

Height of bit:230mm

Gauge length: 51mm

API Connection: 3 -1/2 REG.PIN

Net weight: 22 KGS

- Product Description

Petroleum Drilling Equipment PDC: Advanced Solutions for Efficient Drilling

SHAANXI HAINAISEN INTELLIGENT EQUIPMENT MANUFACTURING CO.,LTD is a leading manufacturer and supplier of Petroleum Drilling Equipment PDC. With over a decade of experience, our company offers cutting-edge Polycrystalline Diamond Compact (PDC) drill bits that revolutionize oil and gas exploration. Our innovative product solutions combine durability, precision, and cost-effectiveness to meet the demanding needs of the energy sector.

Why Choose Our Petroleum Drilling Equipment PDC?

- Superior wear resistance for extended bit life

- Enhanced cutting efficiency in various formations

- Optimized hydraulics for improved hole cleaning

- Customizable designs to suit specific drilling conditions

- Backed by extensive R&D and field-proven performance

Operating Parameters

| Parameter | Range |

|---|---|

| Speed (R/min) | 80-300 |

| Drilling Pressure (KN) | 10-100 |

| Flow Rate (LPS) | 20-35 |

| Applicable Strata | Medium hardness, low compressive strength (e.g., shale, limestone, sandstone, gypsum) |

Applications

Our Petroleum Drilling Equipment PDC finds extensive use in:

- Oil and gas exploration and production

- Geothermal drilling operations

- Coal bed methane extraction

- Hard rock mining and mineral exploration

- Water well drilling and construction

- Horizontal directional drilling for pipeline installation

Customization Services

We understand that every drilling project is unique. Our team of experts works closely with clients to design and manufacture custom product solutions. We consider factors such as formation characteristics, well depth, and operational requirements to deliver tailored products that maximize performance and reduce overall drilling costs.

Material

Our product utilizes premium-grade polycrystalline diamond compacts and tungsten carbide matrix materials. This combination ensures exceptional durability, thermal stability, and impact resistance, even in the most challenging drilling environments.

Quality Control

At HAINAISEN, quality is paramount. Our product undergoes rigorous testing and inspection at every stage of production. We adhere to strict international standards and employ advanced quality management systems to ensure consistent, reliable performance in the field.

Why Choose HAINAISEN

- Industry-leading expertise in PDC technology

- Commitment to continuous innovation and improvement

- Comprehensive technical support and after-sales service

- Competitive pricing without compromising on quality

- Global reputation for reliability and customer satisfaction

Shipment Samples

We offer sample product units for evaluation. Contact our sales team to arrange a sample shipment and experience the HAINAISEN difference firsthand.

Packaging and Transportation

Our products are meticulously packaged with durable materials to safeguard against transit damage, featuring reinforced structures for added protection. We offer adaptable shipping solutions and collaborate with trusted logistics providers to ensure prompt, secure delivery to your doorstep, prioritizing both efficiency and reliability.

Transaction Feedback

Customer feedback is integral to our commitment to excellence, as we continuously refine our products and services based on your insights. Our dedicated support team stands ready to address any concerns, actively listening to your experiences to foster improvements and ensure your satisfaction remains our top priority.

After-Sales Service

HAINAISEN delivers comprehensive after-sales support, with technical experts available to provide personalized guidance on product usage, maintenance, and troubleshooting. Our goal is to optimize the longevity and performance of your investment, ensuring you receive ongoing assistance to maximize the value of our solutions.

Qualification Certification

Our product meets or exceeds industry standards. We hold relevant certifications, including ISO 9001:2015 for quality management, demonstrating our commitment to excellence in manufacturing and customer satisfaction.

FAQ

Q: What is the typical lifespan of your product?

A: The lifespan varies depending on operating conditions, but our PDC bits typically last 30-50% longer than conventional bits.

Q: Can your product be used in high-temperature wells?

A: Yes, our PDC bits are designed to withstand high temperatures commonly encountered in deep drilling operations.

Q: Do you offer training on proper use of your product?

A: Absolutely. We provide comprehensive training and support to ensure optimal performance of our products.

Q: What is the lead time for custom product orders?

A: Lead times vary based on specifications, but we typically deliver custom orders within 4-6 weeks.

Q: Are your products environmentally friendly?

A: Yes, our products are designed to minimize environmental impact through efficient drilling and reduced waste generation.

Contact Us

For inquiries about our Petroleum Drilling Equipment PDC or to request a quote, please email us at hainaisen@hnsdrillbit.com.