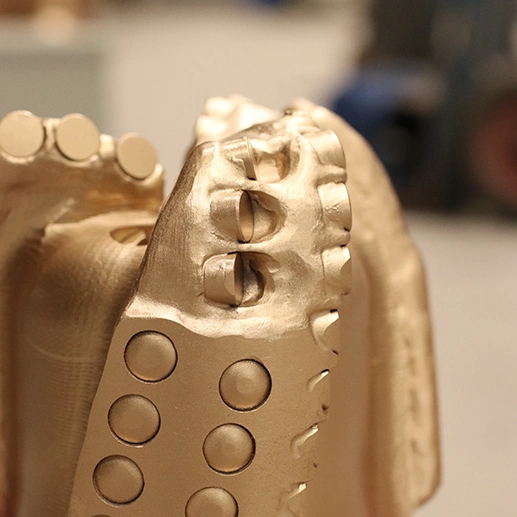

Three Blade PDC Tricone Drill Bit

Bit size:6”(152.4mm)

Number of blade: 3

Number of nozzle: 3

PDC cutter size:13mm

Total number of PDC cutters : 61

Height of bit:220mm

Gauge length: 65mm

API Connection: 3 -1/2 REG.PIN

Net weight: 22 KGS

- Product Description

Three Blade PDC Tricone Drill Bit: High-Performance Drilling Solution

SHAANXI HAINAISEN INTELLIGENT EQUIPMENT MANUFACTURING CO.,LTD is a leading manufacturer and supplier of Three Blade PDC Tricone Drill Bits. Our advanced technology and decades of industry expertise allow us to produce high-quality, efficient drilling tools. Our products offer superior performance, durability, and cost-effectiveness for various drilling applications in the oil, gas, and mining industries.

Why Choose Our Three Blade PDC Tricone Drill Bit?

- Exceptional cutting efficiency and penetration rates

- Improved stability and reduced vibration

- Enhanced durability for longer bit life

- Optimized hydraulics for better cleaning and cooling

- Suitable for a wide range of formations

- Cost-effective solution for drilling operations

Operating Parameters

| Parameter | Specification |

|---|---|

| Speed (R/min) | 80-300 |

| Drilling Pressure (KN) | 10-100 |

| Flow Rate (LPS) | 20-35 |

| Applicable Strata | Medium hardness, low compressive strength (e.g., shale, limestone, sandstone, gypsum) |

Applications

- Oil and gas exploration and production

- Coal bed methane drilling

- Geothermal well drilling

- Water well drilling

- Mining and quarrying operations

- Geological exploration and sampling

Customization Service

We understand that every drilling project has unique requirements. Our team of experienced engineers works closely with clients to design and manufacture custom Three Blade PDC Tricone Drill Bits tailored to specific formation characteristics and operational needs. This ensures optimal performance and cost-effectiveness for your drilling operations.

Material

Our products are crafted using premium-grade materials, including high-strength steel bodies and advanced PDC cutters. This combination ensures maximum durability, wear resistance, and cutting efficiency in challenging drilling environments.

Quality Control

At SHAANXI HAINAISEN, we maintain stringent quality control measures throughout the manufacturing process. Each product undergoes rigorous testing and inspection to ensure it meets our high standards and industry specifications.

Why Choose HAINAISEN

- Over 10 years of industry experience

- State-of-the-art manufacturing facilities

- Experienced R&D team

- Commitment to innovation and continuous improvement

- Excellent customer service and technical support

Shipment Samples

We are delighted to provide sample products designed specifically for comprehensive evaluation and testing. Whether you aim to assess compatibility with your projects, validate performance under real - world conditions, or explore new solutions for your business, our samples offer a hands - on opportunity to experience our offerings firsthand. Simply reach out to our dedicated sales team to share your unique requirements. They will work closely with you to understand your needs, recommend suitable samples, and efficiently arrange for prompt shipment. Don’t hesitate to take this step—contact us today to initiate a seamless sampling process and discover how our products can meet your expectations.

Packaging and Transportation

Our drill bits are carefully packaged in sturdy wooden crates or metal boxes to ensure safe transportation. We work with reliable logistics partners to deliver your order efficiently and securely.

Transaction Feedback

We value customer feedback and continuously strive to improve our products and services. Our team follows up on every transaction to ensure customer satisfaction and address any concerns promptly.

After-Sales Service

Our commitment to you doesn't end with the sale. We provide comprehensive after-sales support, including technical assistance, performance optimization, and prompt resolution of any issues.

Qualification Certification

SHAANXI HAINAISEN is a certified high-tech enterprise with ISO 9001:2015 quality management system certification. Our products meet industry standards and regulations.

FAQ

Q: What is the typical lifespan of a product?

A: The lifespan varies depending on formation and operating conditions but typically ranges from 100 to 300 drilling hours.

Q: Can your products be repaired or refurbished?

A: Yes, we offer repair and refurbishment services to extend the life of your drill bits.

Q: What is the lead time for custom products?

A: Lead times for custom orders typically range from 4 to 6 weeks, depending on complexity and quantity.

Q: Do you offer technical training for proper bit selection and operation?

A: Yes, we provide comprehensive training and support to ensure optimal bit performance.

Q: What warranty do you offer on your products?

A: We offer a standard warranty against manufacturing defects. Extended warranties are available upon request.

Contact Us

For more information about our Three Blade PDC Tricone Drill Bits or to discuss your drilling requirements, please contact us at hainaisen@hnsdrillbit.com.

VIEW MORESeven Blade Wing Oil Drilling Drill Bit

VIEW MORESeven Blade Wing Oil Drilling Drill Bit VIEW MORE113mm Three Wing Arc Angle Drill Bit

VIEW MORE113mm Three Wing Arc Angle Drill Bit VIEW MORE3 Blades PDC Rock Bit

VIEW MORE3 Blades PDC Rock Bit VIEW MOREHard Alloy Scraper Drill Bit

VIEW MOREHard Alloy Scraper Drill Bit VIEW MOREFive Blades Oil Well Drill Head

VIEW MOREFive Blades Oil Well Drill Head VIEW MOREThree Blades Rock Drill Bit

VIEW MOREThree Blades Rock Drill Bit VIEW MOREFour Blade Wing Oil Drilling Tool

VIEW MOREFour Blade Wing Oil Drilling Tool VIEW MOREThree Blade Oil Drill Bit

VIEW MOREThree Blade Oil Drill Bit