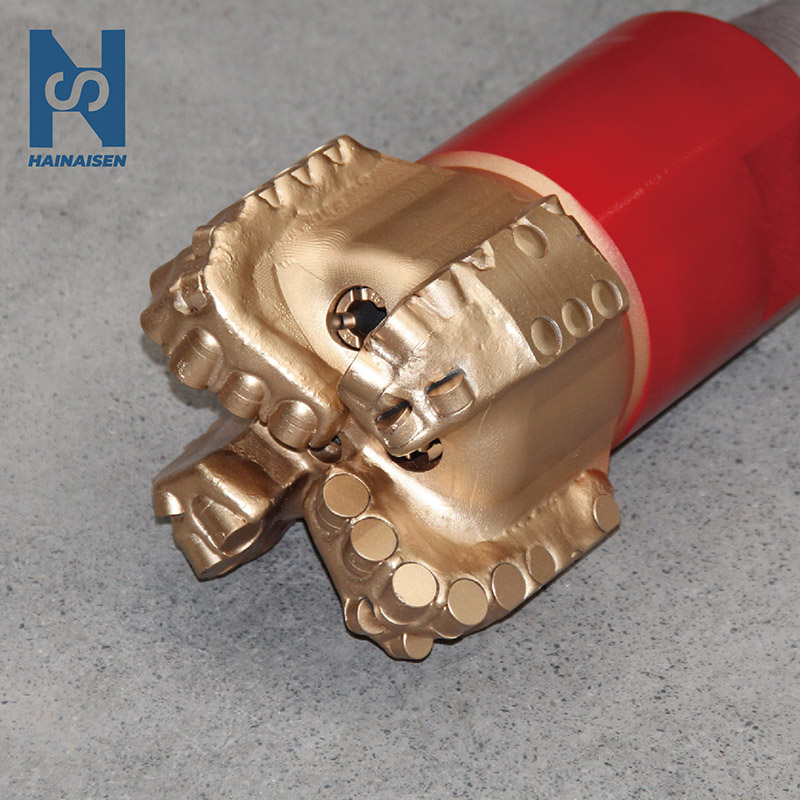

Four Blade Wing Oil Drilling Tool

Bit size:6”(152.4mm)

Number of blade: 4

Number of nozzle: 4

PDC cutter size:13mm/16mm

Total number of PDC cutters : 45

Height of bit:210mm

Gauge length: 53mm

API Connection: 3 -1/2 REG.PIN

Net weight: 24 KGS

- Product Description

SHAANXI HAINAISEN: Your Trusted Four Blade Wing Oil Drilling Tool Manufacturer

As a leading Four Blade Wing Oil Drilling Tool manufacturer and supplier, SHAANXI HAINAISEN INTELLIGENT EQUIPMENT MANUFACTURING CO.,LTD offers superior quality and innovative drilling solutions. Our product stands out for its durability, efficiency, and precision in various drilling applications. With years of expertise and cutting-edge technology, we deliver tools that meet the demanding needs of the oil and gas industry.

Why Choose Our Four Blade Wing Oil Drilling Tool?

- Enhanced drilling efficiency with optimized blade design

- Superior wear resistance for extended tool life

- Excellent stability and control in various formations

- Reduced drilling time and operational costs

- Compatible with a wide range of drilling conditions

- Backed by our experienced technical support team

Operating Parameters

| Parameter | Specification |

|---|---|

| Speed (R/min) | 80-300 |

| Drilling Pressure (KN) | 10-100 |

| Flow Rate (LPS) | 20-35 |

| Applicable Strata | Medium hardness, low compressive strength (e.g., shale, limestone, sandstone, gypsum) |

Application

Our Four Blade Wing Oil Drilling Tool is ideal for:

- Oil and gas exploration and production

- Geothermal drilling projects

- Coal bed methane extraction

- Water well drilling

- Mineral exploration in medium-hard formations

- Directional drilling operations

Customization Service

We understand that every drilling project is unique. That's why we offer customized product solutions tailored to your specific requirements. Our team of experts works closely with you to design and manufacture tools that perfectly match your operational needs, ensuring optimal performance and efficiency.

Material

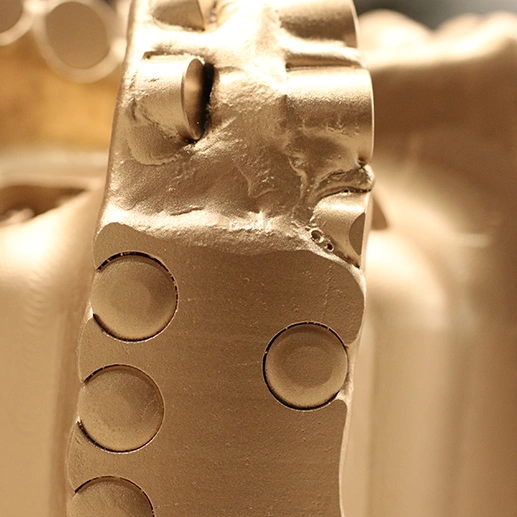

Our product is crafted from high-grade materials, including:

- Premium-grade steel body for durability

- Tungsten carbide inserts for enhanced wear resistance

- Advanced PDC cutters for superior cutting efficiency

Quality Control

At SHAANXI HAINAISEN, quality is our top priority. Our product undergoes rigorous testing and inspection processes, including:

- Dimensional accuracy checks

- Material composition analysis

- Performance simulations

- Field testing in various conditions

Why Choose HAINAISEN

- Over a decade of industry experience

- State-of-the-art manufacturing facilities

- Continuous innovation and R&D

- Excellent customer support and after-sales service

- Competitive pricing without compromising quality

Shipment Samples

We are pleased to provide sample products for evaluation, allowing you to assess their quality, performance, and suitability for your needs. Simply contact our team to arrange a sample shipment, and you’ll experience the HAINAISEN difference firsthand—from meticulous craftsmanship to innovative design that sets our offerings apart in functionality and reliability. Don’t miss this opportunity to discover why our products stand out; reach out today to start your trial.

Packaging and Transportation

Our products are carefully packaged to ensure safe transportation:

- Sturdy wooden crates or pallets

- Protective wrapping to prevent damage

- Clear labeling for easy identification

- Flexible shipping options to meet your timeline

Transaction Feedback

We value your feedback and continuously strive to improve our products and services. Share your experience with our product, and let us know how we can serve you better.

After-Sales Service

Our commitment doesn't end with the sale. We provide comprehensive after-sales support, including:

- Technical assistance and troubleshooting

- Maintenance guidance

- Spare parts supply

- Performance optimization recommendations

Qualification Certification

SHAANXI HAINAISEN holds various industry certifications, demonstrating our commitment to quality and safety standards in product manufacturing.

FAQ

Q: What is the lifespan of your product?

A: The lifespan varies depending on usage conditions, but typically ranges from 100-200 hours of operation.

Q: Can your product be used in high-temperature environments?

A: Yes, our tools are designed to withstand temperatures up to 150°C (302°F).

Q: Do you offer training on how to use the product?

A: Yes, we provide comprehensive training and documentation for optimal tool usage.

Q: What is the lead time for custom product orders?

A: Custom orders typically take 4-6 weeks, depending on specifications and quantity.

Q: Do you offer a warranty on your product?

A: Yes, we provide a standard 12-month warranty against manufacturing defects.

Contact Us

For inquiries about our Four Blade Wing Oil Drilling Tool or any other products, please email us at postmaster@hnsdrillbit.com.

VIEW MORESeven Blade Wing Oil Drilling Drill Bit

VIEW MORESeven Blade Wing Oil Drilling Drill Bit VIEW MOREPDC Flat Top Sintered Drill Bit

VIEW MOREPDC Flat Top Sintered Drill Bit VIEW MOREDrilling Tool Coal Mining Bit

VIEW MOREDrilling Tool Coal Mining Bit VIEW MOREPetroleum PDC Oil Drill Bit

VIEW MOREPetroleum PDC Oil Drill Bit VIEW MOREFive Blades Oil Well Drill Head

VIEW MOREFive Blades Oil Well Drill Head VIEW MOREThree Blade PDC Tricone Drill Bit

VIEW MOREThree Blade PDC Tricone Drill Bit VIEW MOREThree Blades Rock Drill Bit

VIEW MOREThree Blades Rock Drill Bit VIEW MOREThree Blade Oil Drill Bit

VIEW MOREThree Blade Oil Drill Bit