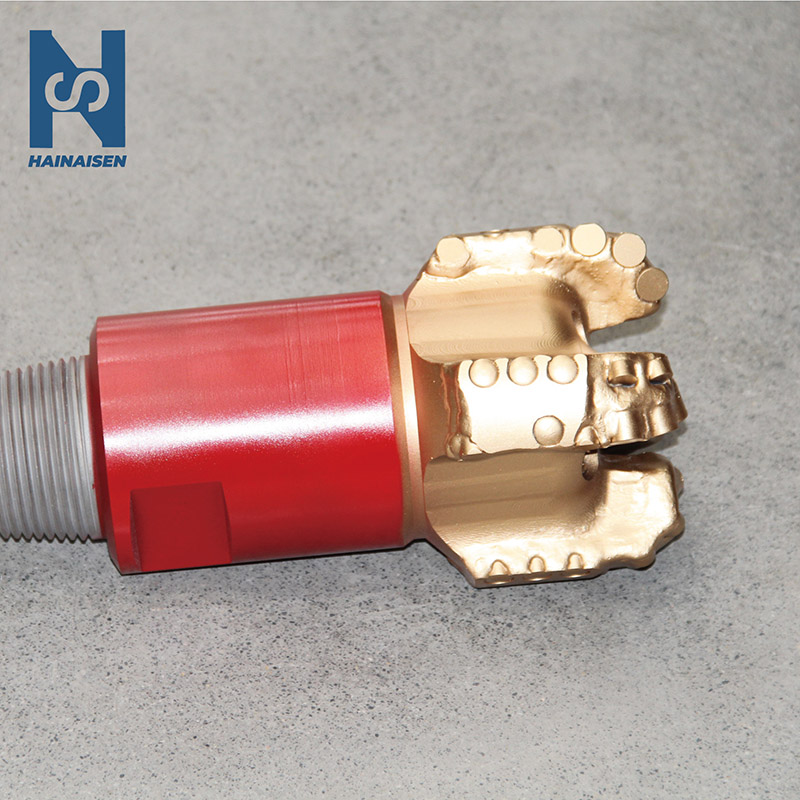

Petroleum PDC Oil Drill Bit

Bit size:6.5”(165.1mm)

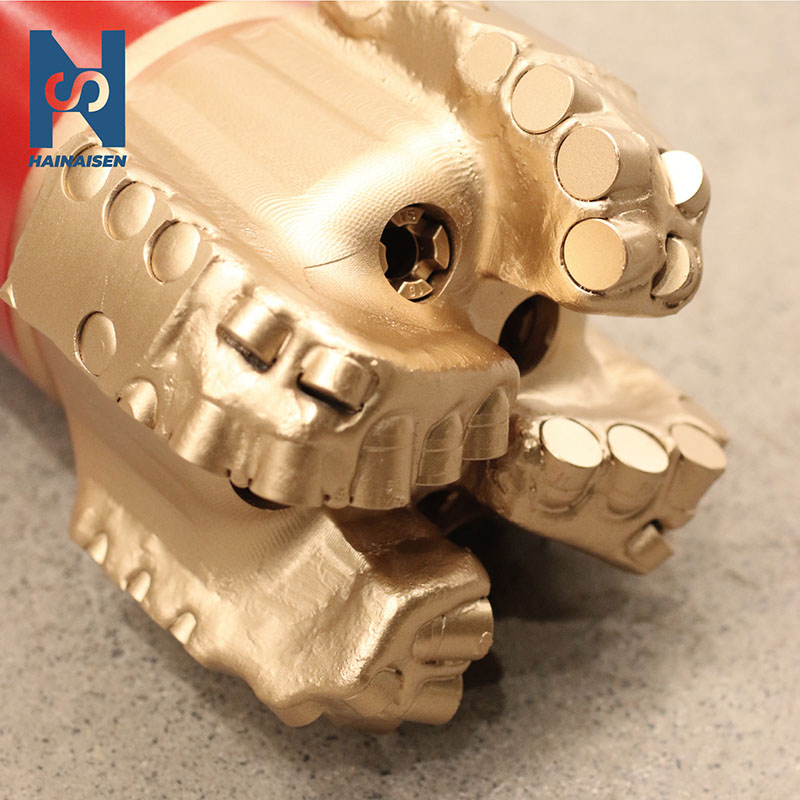

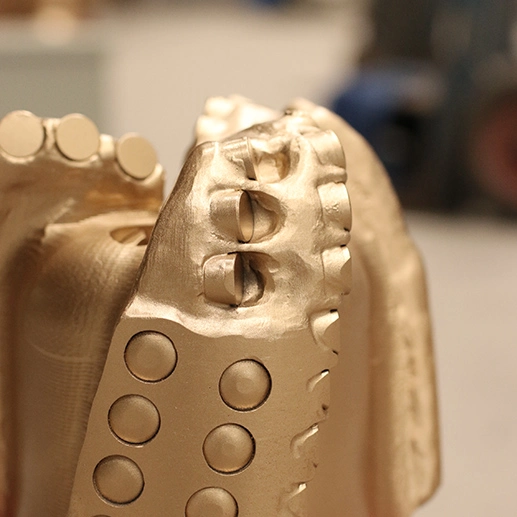

Number of blade: 4

Number of nozzle: 4

PDC cutter size:13mm/16mm

Total number of PDC cutters : 50

Height of bit:230mm

Gauge length: 51mm

API Connection: 3 -1/2 REG.PIN

Net weight: 22 KGS

- Product Description

Revolutionize Your Drilling Operations with HAINAISEN's Petroleum PDC Oil Drill Bits

As a leading manufacturer and supplier of high-performance drilling tools, SHAANXI HAINAISEN INTELLIGENT EQUIPMENT MANUFACTURING CO.,LTD proudly presents our cutting-edge Petroleum PDC Oil Drill Bits. With over a decade of industry expertise, we've engineered these bits to maximize efficiency and durability in oil and gas exploration. Our products stand out for their advanced polycrystalline diamond compact technology, ensuring superior wear resistance and penetration rates in challenging formations.

Why Choose Our Petroleum PDC Oil Drill Bits?

- Superior Durability: Engineered with premium-grade materials for extended bit life

- Enhanced Performance: Optimized cutter placement for faster penetration rates

- Versatile Application: Suitable for various formation types, from soft to medium-hard

- Cost-Effective: Reduced trips and increased ROP for improved operational efficiency

- Customizable Design: Tailored solutions to meet specific drilling requirements

Operating Parameters

| Parameter | Value Range |

|---|---|

| Speed (R/min) | 80-300 |

| Drilling Pressure (KN) | 10-100 |

| Flow Rate (LPS) | 20-35 |

| Applicable Strata | Medium hardness, low compressive strength (e.g., shale, limestone, sandstone, gypsum) |

Application

Our Petroleum PDC Oil Drill Bits excel in:

- Offshore and onshore oil exploration

- Natural gas drilling operations

- Geothermal well construction

- Hard rock mining projects

- Water well drilling in challenging formations

- Geological core sampling and exploration

These versatile bits are designed to tackle a wide range of drilling conditions, offering consistent performance across various depths and formations. Their advanced design ensures optimal weight transfer and hydraulic efficiency, resulting in smoother operations and reduced drilling time.

Customization Service

At HAINAISEN, we understand that every drilling project is unique. Our team of expert engineers works closely with clients to develop customized products tailored to specific geological challenges and operational requirements. We offer personalized consultations to determine the ideal bit configuration, cutter size, and blade design for your project needs.

Material

Our products feature high-grade steel bodies and premium polycrystalline diamond compact cutters. This combination ensures exceptional strength, thermal stability, and wear resistance, even in the most demanding drilling environments.

Quality Control

HAINAISEN maintains rigorous quality control measures throughout the manufacturing process. Each product undergoes thorough inspections and testing to ensure it meets our stringent performance and safety standards before leaving our facility.

Why Choose HAINAISEN

- Industry-leading R&D capabilities

- Proven track record of successful global projects

- Comprehensive technical support and after-sales service

- Competitive pricing without compromising on quality

- Commitment to continuous innovation and improvement

Shipment Samples

We offer sample products for evaluation upon request. Contact our sales team to discuss your specific requirements and arrange for a sample shipment.

Packaging and Transportation

Our products are carefully packaged in sturdy, protective cases to ensure safe transportation. We work with reliable logistics partners to deliver your order efficiently and securely, anywhere in the world.

Transaction Feedback

We value customer satisfaction and continuously seek feedback to improve our products and services. Our team follows up after each transaction to ensure your products meet or exceed expectations.

After Sales Service

HAINAISEN provides comprehensive after-sales support, including:

- Technical guidance for optimal bit selection and operation

- Troubleshooting assistance

- Performance analysis and recommendations

- Warranty support and timely replacements if needed

Qualification Certification

Our products are manufactured in compliance with international industry standards. HAINAISEN holds relevant certifications, including ISO 9001:2015 for quality management systems.

FAQ

Q: What is the typical lifespan of your products?

A: The lifespan varies depending on formation and operating conditions, but our bits typically outperform conventional options by 30-50%.

Q: Can your bits be re-sharpened or refurbished?

A: Yes, we offer re-sharpening and refurbishment services to extend the life of your products.

Q: Do you provide field support for your products?

A: Absolutely. Our technical team can provide on-site support and training upon request.

Q: What's the lead time for custom products?

A: Lead times for custom orders typically range from 4-6 weeks, depending on complexity and quantity.

Q: Are your products compatible with standard drilling equipment?

A: Yes, our bits are designed to be compatible with industry-standard drilling systems and equipment.

Contact Us

Ready to enhance your drilling operations with our high-performance Petroleum PDC Oil Drill Bits? Contact us today at hainaisen@hnsdrillbit.com for inquiries, quotes, or to discuss your specific drilling challenges.

VIEW MOREDiamond Oil Drill Bit

VIEW MOREDiamond Oil Drill Bit VIEW MOREFive Wing PDC Bit For Hard Rock Drilling

VIEW MOREFive Wing PDC Bit For Hard Rock Drilling VIEW MOREOil Diamond Drill Bit

VIEW MOREOil Diamond Drill Bit VIEW MOREDiamond Drill Bits For Oil Rigs

VIEW MOREDiamond Drill Bits For Oil Rigs VIEW MOREDrilling Bit For Oil And Gas Rig

VIEW MOREDrilling Bit For Oil And Gas Rig VIEW MOREPetroleum Drilling Equipment PDC

VIEW MOREPetroleum Drilling Equipment PDC VIEW MOREHigh Quality PDC Drill Bits

VIEW MOREHigh Quality PDC Drill Bits VIEW MOREDiamond Drill Bit Oil Rig

VIEW MOREDiamond Drill Bit Oil Rig