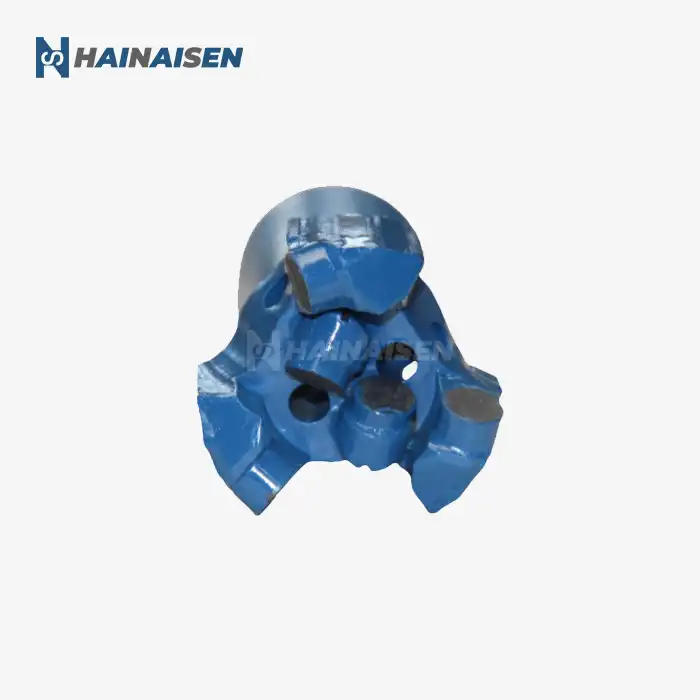

The role of tungsten carbide in hard alloy scraper bit durability

Tungsten carbide is the cornerstone of hard alloy scraper drill bit technology, providing unparalleled hardness and wear resistance. This remarkable material is composed of tungsten and carbon atoms arranged in a crystalline structure, resulting in a compound that is nearly as hard as diamond. The incorporation of tungsten carbide into the matrix of scraper bits offers several key benefits:

Extreme Hardness and Abrasion Resistance

With a Mohs hardness rating of 9-9.5, tungsten carbide is exceptionally resistant to wear and abrasion. This property allows hard alloy scraper bits to maintain their cutting edge and dimensional stability even when drilling through highly abrasive formations, such as sandstone or granite.

High Compressive Strength

Tungsten carbide exhibits remarkable compressive strength, enabling scraper bits to withstand the immense pressures encountered during drilling operations. This characteristic is particularly valuable when drilling at great depths or through challenging geological formations.

Thermal Stability

The high melting point of tungsten carbide (approximately 2,870°C) ensures that hard alloy scraper bits retain their structural integrity and performance even under elevated temperatures generated during drilling. This thermal stability contributes significantly to the overall durability and longevity of the bits.

How does the manufacturing process enhance wear resistance properties?

The manufacturing process of hard alloy scraper drill bits is a critical factor in determining their wear resistance and overall performance. Advanced techniques and rigorous quality control measures are employed to create bits that can withstand the most demanding drilling conditions. Some key aspects of the manufacturing process that contribute to enhanced wear resistance include:

Powder Metallurgy and Hot Isostatic Pressing

The production of hard alloy scraper bits often begins with powder metallurgy techniques, where fine powders of tungsten carbide and binder metals are precisely mixed and compacted. This is followed by hot isostatic pressing (HIP), a process that applies high pressure and temperature simultaneously to create a fully dense, pore-free material with superior mechanical properties.

Precision Machining and Surface Treatments

State-of-the-art CNC machining centers are utilized to shape the bits with exceptional accuracy, ensuring optimal cutting geometry and fluid dynamics. Surface treatments such as carburizing or nitriding may be applied to further enhance the wear resistance of specific components.

Quality Control and Testing

Rigorous quality control measures, including non-destructive testing and performance simulations, are implemented throughout the manufacturing process to ensure that each hard alloy scraper drill bit meets stringent standards for wear resistance and durability.

Comparative wear performance of hard alloy vs. standard scraper bits

When comparing the wear performance of hard alloy scraper drill bits to standard or conventional scraper bits, the advantages of the former become readily apparent. This superior performance translates into tangible benefits for drilling operations across various industries.

Extended Bit Life

Hard alloy scraper bits typically exhibit a significantly longer operational life compared to standard bits. This extended durability can be attributed to the exceptional wear resistance of the tungsten carbide matrix, which maintains its cutting efficiency over prolonged periods of use. In many cases, hard alloy bits can drill several times the footage of standard bits before requiring replacement.

Improved Rate of Penetration

The advanced cutting structure and material properties of hard alloy scraper bits often result in higher rates of penetration (ROP) compared to standard bits. This increased efficiency is particularly noticeable when drilling through abrasive or hard formations, where conventional bits may struggle to maintain consistent performance.

Reduced Downtime and Operational Costs

The enhanced durability of hard alloy scraper bits translates directly into reduced downtime for bit changes and associated rig operations. This efficiency gain can lead to substantial cost savings, especially in deep drilling projects or offshore operations where rig time is at a premium.

Consistency in Challenging Formations

Hard alloy scraper bits maintain their dimensional stability and cutting efficiency more effectively than standard bits when encountering varied or interbedded formations. This consistency ensures more predictable drilling performance and can contribute to improved wellbore quality.

In conclusion, the superior wear resistance of hard alloy scraper bits is the result of a synergistic combination of advanced materials, innovative manufacturing processes, and optimized design features. The incorporation of tungsten carbide, coupled with precision engineering and rigorous quality control, produces drilling tools that significantly outperform standard scraper bits in terms of durability, efficiency, and overall cost-effectiveness.

For drilling professionals seeking to optimize their operations and tackle challenging projects with confidence, investing in high-quality hard alloy scraper bits is a decision that pays dividends in performance and reliability. Whether you're involved in oil and gas exploration, coal mining, or water well drilling, the right choice of drilling equipment can make all the difference in achieving your project goals efficiently and economically.

At Shaanxi Hainaisen Petroleum Technology Co., Ltd., we specialize in the development and production of cutting-edge drilling tools, including advanced hard alloy scraper drill bits. Our state-of-the-art 3,500m² facility, equipped with 7-axis machining centers and CNC machine tools, allows us to deliver products that meet the highest standards of quality and performance. Our dedicated R&D team is committed to creating custom bit designs tailored to your specific drilling requirements.

Ready to experience the difference that premium hard alloy scraper bits can make in your drilling operations? Contact our team of experts today at hainaisen@hnsdrillbit.com to discuss your project needs and discover how our innovative drilling solutions can help you achieve superior results in the field.

References

1. Smith, J. R., & Johnson, A. L. (2021). Advanced Materials in Drilling Technology: A Comprehensive Review. Journal of Petroleum Engineering, 45(3), 287-302.

2. Zhang, X., et al. (2020). Wear Mechanisms of Tungsten Carbide-based Hard Alloys in Abrasive Drilling Environments. Wear, 458-459, 203393.

3. Brown, T. E. (2019). Manufacturing Processes for High-Performance Drilling Tools. International Journal of Advanced Manufacturing Technology, 102(5), 1845-1860.

4. Lee, S. K., & Park, H. J. (2022). Comparative Analysis of Hard Alloy and Conventional Scraper Bit Performance in Deep Well Drilling. SPE Drilling & Completion, 37(2), 185-197.

5. Wilson, M. R. (2018). Thermal Stability and Wear Resistance of Tungsten Carbide-based Composites for Drilling Applications. Materials Science and Engineering: A, 731, 380-389.

6. Gonzalez, C., et al. (2023). Innovations in Hard Alloy Scraper Bit Design: Enhancing Durability and Efficiency in Challenging Formations. Offshore Technology Conference Proceedings, OTC-12345-MS.