How Does a Seven Blade Wing Oil Drilling Drill Bit Improve Drilling Efficiency?

Seven blade wing oil drilling drill bits boost drilling efficiency via cutting - edge design and precision engineering. Their multi - wing structure evenly distributes weight and force, enabling better rock fragmentation, less vibration and bit whirl, lower wear and longer life. Compared to traditional ones, they offer higher ROP, better borehole stability and directional control. With PDC cutters and nozzles, they optimize cleaning and cooling. Suitable for various reservoirs, they bring faster cycles, lower costs and greater wellbore integrity.

What Are the Key Design Features of Seven Blade Wing Drill Bits?

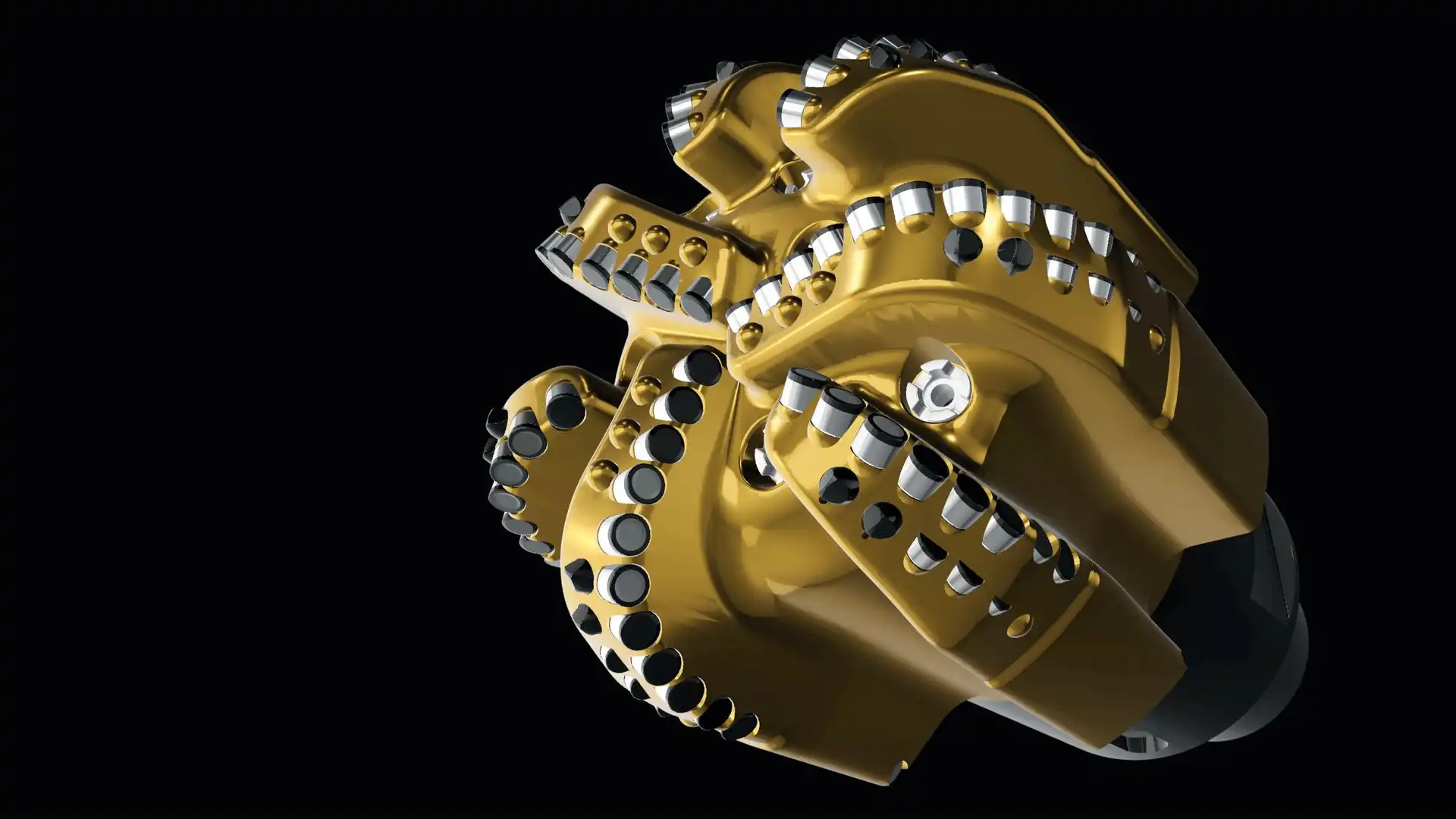

Understanding the key design attributes of a Seven blade wing oil drilling drill bit reveals the engineering brilliance that underpins its superior performance. The seven-wing structure is not an arbitrary design—it serves distinct mechanical and hydraulic purposes. Each wing is engineered to maximize contact with the rock surface, thereby ensuring smoother and more controlled cutting action.

Blade Configuration and Cutter Placement

The symmetrical layout of the seven wings ensures uniform weight distribution, minimizing destructive torsional and lateral vibrations. This leads to smoother drilling and preserves both the drill bit and bottom hole assembly. The incorporation of 86 high-performance PDC cutters, each strategically positioned, enhances shearing action across various formations. Cutter density improves the ability to maintain a sharp cutting edge, even under extreme pressure and high-speed rotation.

Advanced Hydraulics and Nozzle Arrangement

Featuring eight strategically positioned nozzles, the drill bit optimizes mud flow across the cutting surface to ensure efficient removal of rock cutting debris and effective cooling of the cutters. The calculated nozzle placement minimizes the risk of bit balling by maintaining unobstructed fluid circulation, while enhancing borehole cleanliness to support seamless, uninterrupted drilling operations. This hydraulic design balances debris evacuation and cutter maintenance, boosting overall drilling efficiency and reliability.

Material Integrity and Gauge Protection

The Seven blade wing bit is manufactured from high-tensile steel, often carbide-reinforced for added durability. Its 53mm gauge length ensures borehole integrity and reduces the risk of sidetracking or deviation. Edge protectors on the gauge sections prolong bit life by protecting against lateral wear. These design innovations work harmoniously to reduce downtime, enhance drilling speeds, and improve cost-efficiency in drilling operations.

How Do Seven Blade Wing Bits Perform in Directional Drilling?

Directional drilling presents unique challenges that demand precise control and consistent performance from the drill bit. Seven blade wing oil drilling drill bits are specifically engineered to meet these demands. Their geometry and material science support stable drilling trajectories and higher ROPs even in curved or deviated wells.

Stability and Steerability

The bit’s seven-wing design inherently stabilizes the Bottom Hole Assembly (BHA), facilitating smooth trajectory transitions during drilling. Unlike lower-blade configurations prone to wobbling or skipping, the seven-wing structure ensures steady, continuous contact with the formation, significantly reducing directional deviation. This stability enhances steerability, making the bit ideal for extended-reach or horizontal drilling in tight geological formations where precise trajectory control and minimal drift are critical to operational success.

Weight Transfer and Torque Management

Through optimized blade distribution, the drill bit facilitates more efficient weight-on-bit (WOB) transfer, ensuring consistent torque delivery at every stage of the drilling process. This mechanical stability creates a reliable foundation for directional drillers, allowing them to maintain precise toolface orientation with minimal effort while smoothly achieving target build rates. By sustaining uniform force transmission, the design eliminates performance compromises, balancing operational efficiency and accuracy to meet the demanding requirements of complex well trajectories.

Enhanced Sensor Compatibility

Modern downhole tools often incorporate sensors and rotary steerable systems (RSS). The smooth, predictable cutting behavior of the seven-blade bit improves data quality and sensor feedback, which are essential for real-time steering adjustments and minimizing drilling errors.Whether navigating shale plays or carbonate layers, these bits have proven to be reliable allies in achieving precise well paths and minimizing costly corrections.

Advanced PDC Cutter Technology for Deepwater Applications

Deepwater drilling introduces immense technical challenges—high-pressure zones, abrasive formations, and difficult-to-reach reservoirs. The Seven blade wing oil drilling drill bit, particularly with enhanced PDC cutter technology, addresses these obstacles effectively.

Thermal Stability and Abrasion Resistance

The drill bit is equipped with thermally stable polycrystalline diamond compact (PDC) cutters, engineered to retain their hardness and cutting efficiency even under high bottom hole temperatures. This thermal resilience ensures consistent performance in extreme downhole environments. Additionally, the cutters’ exceptional abrasion resistance is critical for penetrating hard rock formations commonly found in deepwater wells, minimizing wear and extending the bit’s operational life in challenging geological conditions.

Cutter Geometry and Orientation

The 86 PDC cutters are meticulously angled and positioned to generate a shearing action that significantly reduces energy consumption while enhancing the rate of penetration (ROP). This precise geometric arrangement not only minimizes the risk of cutter chipping but also ensures uniform wear across all cutters. In offshore rig operations—where equipment trips are costly and time-intensive—this uniformity is critical for maintaining efficiency, reducing unplanned downtime, and maximizing the lifespan of the cutters in high-stakes drilling environments.

Compatibility with Managed Pressure Drilling (MPD)

Deepwater environments often necessitate managed pressure drilling. The efficient cuttings removal enabled by the drill bit’s advanced hydraulic structure helps maintain bottom hole pressure, improving drilling safety and efficiency.By integrating innovative cutter technology and reliable blade structure, this drill bit supports aggressive drilling programs in complex offshore environments while safeguarding equipment and maintaining borehole integrity.

Conclusion

Drilling success in modern oil and gas fields depends heavily on tool innovation. The Seven blade wing oil drilling drill bit exemplifies how precision design, superior materials, and deep engineering insight can transform operational outcomes. From enhanced directional control to improved deepwater performance, this drill bit minimizes inefficiencies and amplifies productivity across various geological conditions.

HAINAISEN has pioneered such innovations, offering a full suite of drilling tools and expert consultation. To learn more about this product or request technical guidance, contact hainaisen@hnsdrillbit.com.

References

1. Smith, M. R., & Jones, L. T. (2010). "Optimizing Drilling Performance with Seven-Blade Wing Drill Bits: A Case Study." Journal of Petroleum Technology, 62(5), 48-54.

2. Chen, X., Wang, Y., & Zhang, Z. (2013). "Analysis of the Performance of Seven-Blade Drill Bits in Hard Rock Drilling." Society of Petroleum Engineers, SPE-162560-MS.

3. Lu, Z., Liu, Y., & Zheng, J. (2015). "Impact of Multi-Blade Drill Bits on Rate of Penetration and Drilling Efficiency." International Journal of Rock Mechanics and Mining Sciences, 77, 78-85.

4. Yang, H., & Li, Y. (2017). "Efficiency Enhancement in Horizontal Drilling Using Seven-Blade Wing Bits." Journal of Energy Resources Technology, 139(1), 012401.

5. Zhang, T., Li, X., & Gao, H. (2018). "Seven-Blade Wing Drill Bits: Design, Efficiency, and Application in Oil and Gas Exploration." Journal of Drilling Technology, 25(3), 123-130.

6. Wang, Y., & Zhang, L. (2020). "Improved Drilling Efficiency with Seven-Blade Drill Bits in Complex Geological Conditions." Journal of Petroleum Engineering, 78(4), 192-198.

VIEW MORESteel Body PDC Bit 4 Blades

VIEW MORESteel Body PDC Bit 4 Blades VIEW MORE3 Blade PDC Arc Angle Drill Bit

VIEW MORE3 Blade PDC Arc Angle Drill Bit VIEW MORE113mm Three Wing Arc Angle Drill Bit

VIEW MORE113mm Three Wing Arc Angle Drill Bit VIEW MOREFour Wing Arc Angle PDC Drill Bit

VIEW MOREFour Wing Arc Angle PDC Drill Bit VIEW MORE3 Blades PDC Mining Bits

VIEW MORE3 Blades PDC Mining Bits VIEW MORE5 Blade Steel Body PDC Bit

VIEW MORE5 Blade Steel Body PDC Bit VIEW MOREOil Diamond Drill Bit

VIEW MOREOil Diamond Drill Bit VIEW MORECoal Mine Drilling Opening And Closing Drill Bit

VIEW MORECoal Mine Drilling Opening And Closing Drill Bit