Four blade PDC rock drill bit vs. Traditional Drill Bits Key Differences?

When it comes to rock drilling in challenging formations, the Four blade PDC rock drill bit stands out as a high-performance solution. Unlike traditional drill bits that often struggle in hard or abrasive terrains, this advanced design leverages polycrystalline diamond compact (PDC) technology to deliver faster penetration rates, better wear resistance, and longer operational life. Engineered specifically for high-efficiency drilling, the 4 Blade PDC Bit has redefined expectations in the oil, gas, and mining industries—especially where conventional methods fall short.

Why Does Four blade PDC rock drill bits Outperform Traditional Bits in Hard Rock?

Rock drilling in hard geological layers is one of the most technically demanding aspects of the oil and gas industry. Conventional roller cone and steel tooth bits, while serviceable in soft to medium formations, often fail to achieve consistent performance in abrasive, high-compressive-strength rocks. This is where the Four blade PDC rock drill bit comes into its own.

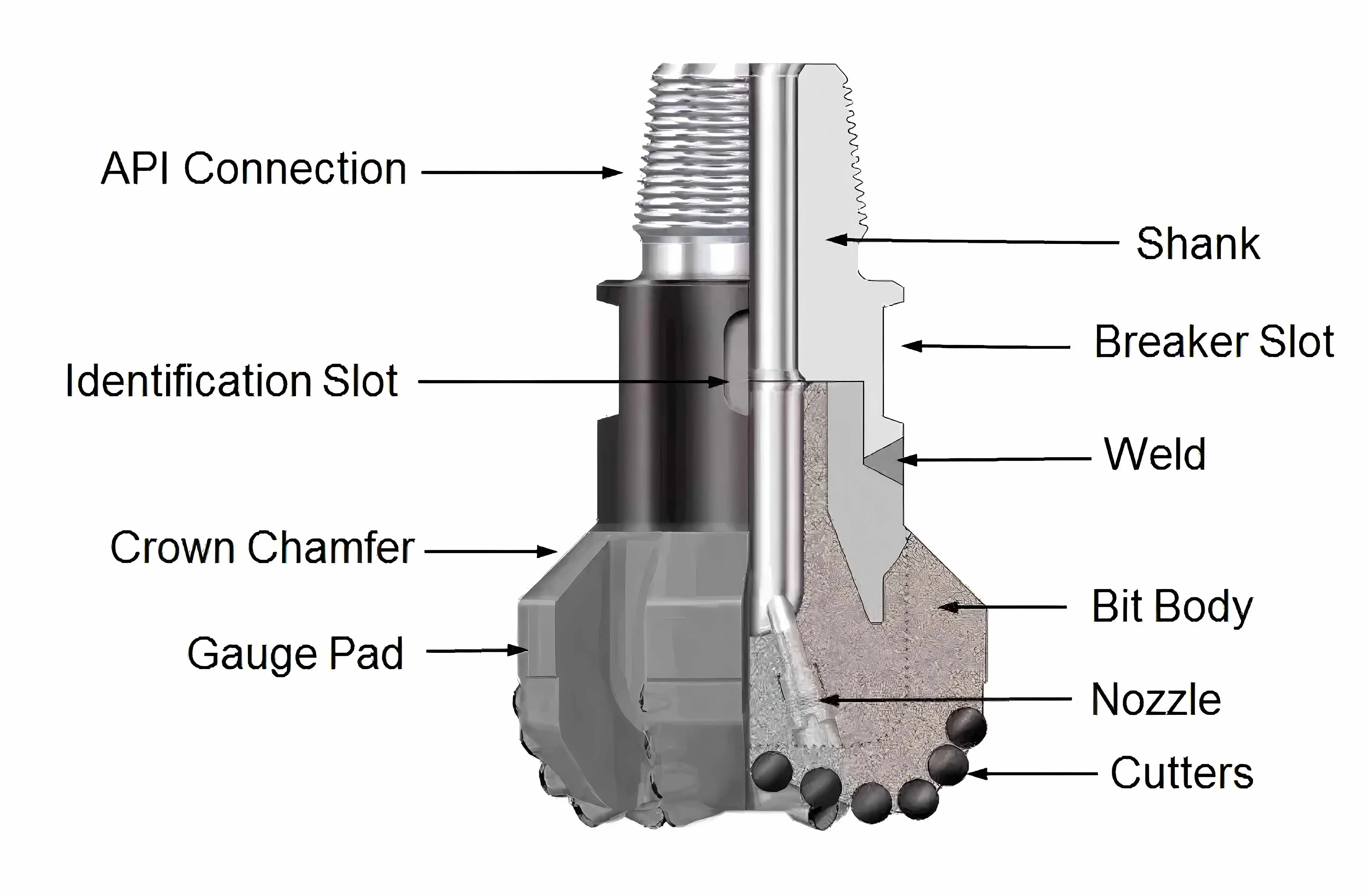

Optimized Blade Geometry

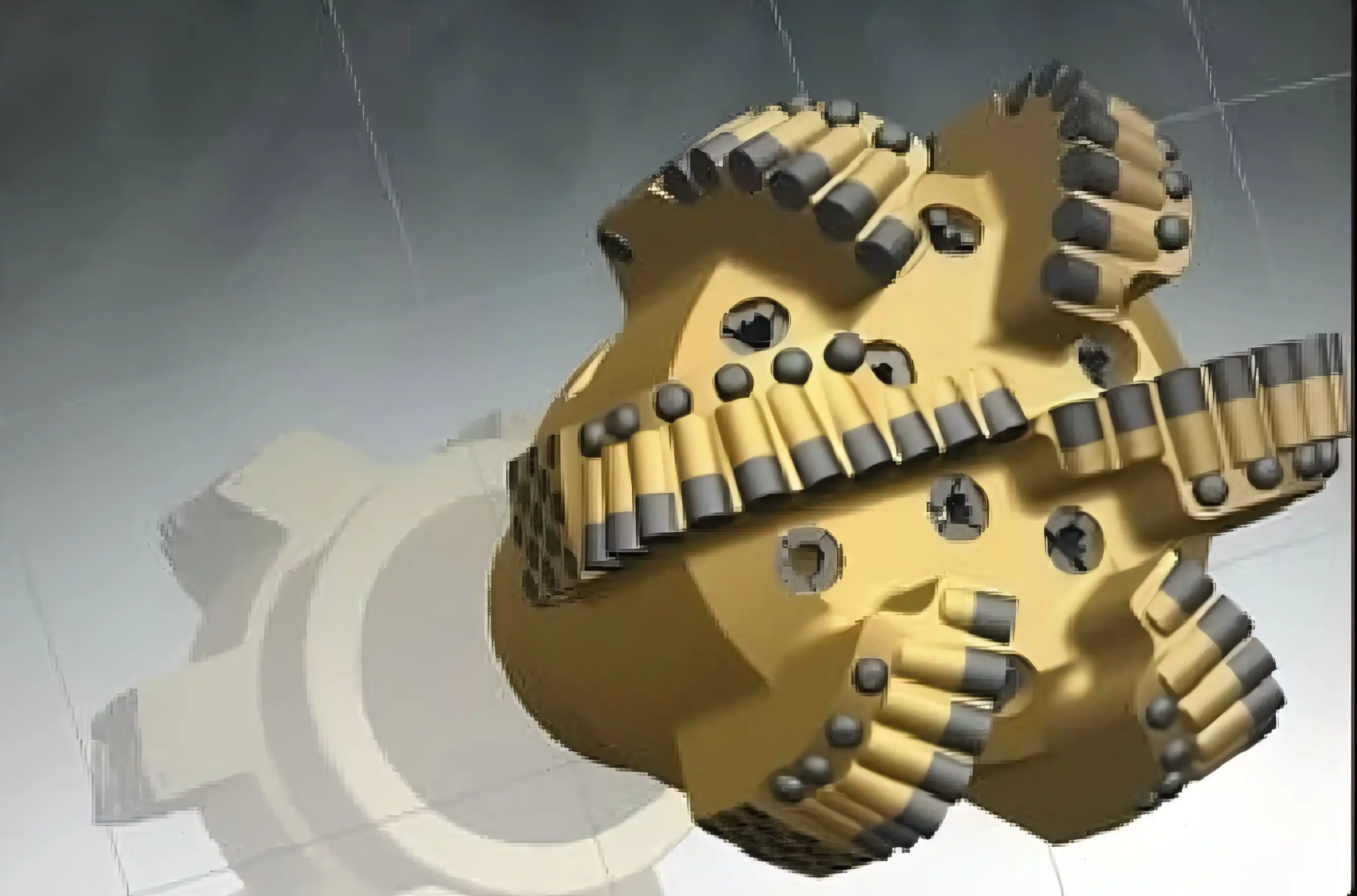

The blade count on a drill bit is not just a design choice—it’s a strategic decision. The 4-blade configuration strikes a fine balance between aggressive cutting and structural integrity. It ensures optimal engagement with the rock surface while maintaining enough durability to withstand high downhole stresses.

Where a traditional bit may chatter or stall, the Four blade PDC rock drill bit maintains smooth, uninterrupted rotation, reducing bit bounce and toolface instability. This makes it particularly effective in directional drilling applications, such as shale or granite beds, where precision and control are paramount.

Thermal and Mechanical Resilience

Hard rock formations like quartzite or basalt exert enormous pressure on drilling tools, both mechanically and thermally. Traditional bits wear down quickly or even shatter under such conditions. In contrast, the Four blade PDC rock drill bitt incorporates synthetic diamond cutters known for their exceptional hardness and heat resistance.

Combined with a robust steel or matrix body, this configuration resists cutter loss and edge degradation. The result? Significantly reduced bit trips, fewer equipment failures, and a higher return on investment for operators.

Stability in Complex Formations

Another key differentiator is the enhanced torque stability. Traditional drill bits often experience torque spikes in fractured formations, which can lead to string vibration, bit whirl, or even catastrophic failure. The 4-blade design, in synergy with its PDC cutters, absorbs torsional shocks more effectively, allowing for stable, continuous rock cutting.

In tests across limestone, dolomite, and high-density shale, operators noted improved steering response and reduced drilling time—metrics that directly impact rig productivity.

Shear Cutting vs. Crushing: Understanding Drilling Mechanisms

To appreciate the technical edge of Four blade PDC rock drill bit, one must explore the underlying science: the difference between shear cutting and crushing. These two mechanisms define the core performance of modern versus traditional drill bits.

The Traditional Crushing Paradigm

Traditional tri-cone or roller-cone bits primarily use a crushing mechanism. They rely on heavy weight-on-bit (WOB) to pulverize the rock surface. While this approach is suitable for soft, unconsolidated formations, it becomes increasingly inefficient as rock strength rises.

Crushing not only consumes more energy but also generates excessive vibration and bit wear. This leads to more frequent tool replacement, downtime, and operational costs.

The Shearing Revolution in PDC Technology

The Four blade PDC rock drill bit uses shear cutting—a far more energy-efficient method for removing rock. Instead of hammering the formation, PDC cutters slice through it, producing finer rock chips and less thermal damage.

This process requires less WOB and generates smoother torque responses. Shearing also enables higher rotary speeds, improving rate of penetration (ROP) without compromising bit longevity.

What’s more, the shearing action reduces the risk of micro-fractures extending into surrounding formation walls, which is crucial when drilling in hydrocarbon-rich zones or unstable rock columns.

Multi-Disciplinary Advantages

From an engineering standpoint, the shear mechanism translates to a lower specific energy requirement—a key performance indicator in drilling optimization. In real-world field studies, rigs using Four blade PDC rock drill bit consistently demonstrated higher ROPs while consuming less hydraulic horsepower.

This dual benefit—speed and efficiency—makes them indispensable for directional and extended-reach drilling where every inch drilled matters.

Superior Wear Resistance & ROP in Hard Rock Formations

High wear resistance and rate of penetration (ROP) are critical KPIs when selecting tools for rock drilling. The Four blade PDC rock drill bit excels in both, thanks to advanced materials, cutter technology, and structural design.

Material Superiority

The PDC cutters used in these bits are composed of micron-sized diamond particles sintered under high temperature and pressure. Their hardness, second only to natural diamond, allows the cutters to maintain sharpness even after extended exposure to hard rocks.

Moreover, these cutters are thermally stable, resisting breakdown at temperatures exceeding 700°C—conditions that would render traditional bits ineffective. Enhanced bonding between cutter and body ensures minimal cutter loss, even in high-impact zones.

Strategic Cutter Layout

The Four blade PDC rock drill bitt incorporates a cutter layout engineered for uniform wear and efficient heat dissipation. This layout minimizes localized stress concentrations and extends bit life, a crucial factor in reducing downtime for bit replacement.

Each blade is designed to carry a balanced load, which mitigates the risk of localized cutter wear and maintains consistent cutting action throughout the bit’s operational cycle.

Optimized ROP Through Design

Traditional drill bits suffer from inconsistent ROP due to vibration, toolface instability, or ineffective cutter engagement. The Four blade PDC rock drill bit improves this through balanced hydraulic flow, cutter orientation, and optimized blade spacing.

As a result, these bits can drill deeper, faster, and with less energy—often reducing total well cost by up to 30%. Operators benefit from shorter drilling cycles, reduced equipment stress, and higher overall productivity.

Real-World Performance Validation

Field data from operators working in high-density carbonate and volcanic formations report that Four blade PDC rock drill bit outperform their traditional counterparts by more than 40% in total footage drilled. Their ability to maintain cutting performance without frequent maintenance makes them the bit of choice in high-stakes projects.

Conclusion

The Four blade PDC rock drill bit represents a seismic shift in rock drilling performance. From its shear cutting capabilities to its superior wear resistance and enhanced ROP, it has proven time and again to be a game-changer for the oil and gas industry. Unlike traditional drill bits that falter in hard rock scenarios, this innovation continues to push the boundaries of what’s possible beneath the Earth’s surface.HAINAISEN has been at the forefront of this change with its deep expertise in advanced drilling solutions. To explore our cutting-edge solutions, reach out at hainaisen@hnsdrillbit.com.

References

1. Drilling Engineering," J.J. Azar – analysis of drilling mechanics and bit performance in rock formations.

2. Advanced Drilling Engineering," G. Robello Samuel – covers bit technology and rate of penetration dynamics.

3. Society of Petroleum Engineers (SPE) Technical Papers – multiple peer-reviewed papers on PDC bit advancements.

4. Applied Drilling Engineering," A.T. Bourgoyne et al. – widely used reference for understanding drilling tools and methods.

5. Handbook of Drilling Technology," M.R. Islam & A.B. Chhetri – discusses modern innovations in drill bit design.

6. International Association of Drilling Contractors (IADC) Reports – comprehensive data on bit performance and tool reliability.

VIEW MORESix Blade Wing Petroleum Drill Bit

VIEW MORESix Blade Wing Petroleum Drill Bit VIEW MOREFive Wing PDC Bit For Hard Rock Drilling

VIEW MOREFive Wing PDC Bit For Hard Rock Drilling VIEW MOREHigh Performance 5 Cutter PDC Bit

VIEW MOREHigh Performance 5 Cutter PDC Bit VIEW MORE113mm PDC Arc Angle Drill Bit

VIEW MORE113mm PDC Arc Angle Drill Bit VIEW MOREFive Blades PDC Drill Bits

VIEW MOREFive Blades PDC Drill Bits VIEW MOREDrilling Bit For Oil And Gas Rig

VIEW MOREDrilling Bit For Oil And Gas Rig VIEW MOREPetroleum Drilling Equipment PDC

VIEW MOREPetroleum Drilling Equipment PDC VIEW MOREHigh Quality PDC Drill Bits

VIEW MOREHigh Quality PDC Drill Bits