What Are the Applications of a 153mm Coal Mine Concave Drill Bit with 3 Blade Wings for Rock Drilling?

The 153mm coal mine concave drill bit with 3 blade wings for rock drilling is a specialized tool engineered for complex geological environments such as those encountered in coal mining and mineral exploration. This particular drill bit excels in penetrating layered rock structures, extracting core samples, and enhancing directional stability in high-pressure underground operations. Its concave geometry, reinforced by three robust blade wings and integrated PDC cutters, ensures high-efficiency drilling with reduced vibration and extended tool life. This makes it ideal for coal seam development, exploratory rock coring, and hard formation drilling across the mining and energy sectors.

How Does the 153mm Concave Design Enhance Rock Drilling Efficiency in Mines?

Concentrated Energy Distribution for Faster Penetration

The concave design of the drill bit facilitates energy concentration at the center, enhancing the initial point of contact with rock. Unlike flat or convex bits, this curvature enables a self-centering effect, reducing lateral drift and increasing drilling precision. In complex formations where maintaining borehole trajectory is critical, this geometry provides superior control.

Superior Cuttings Evacuation through Nozzle Configuration

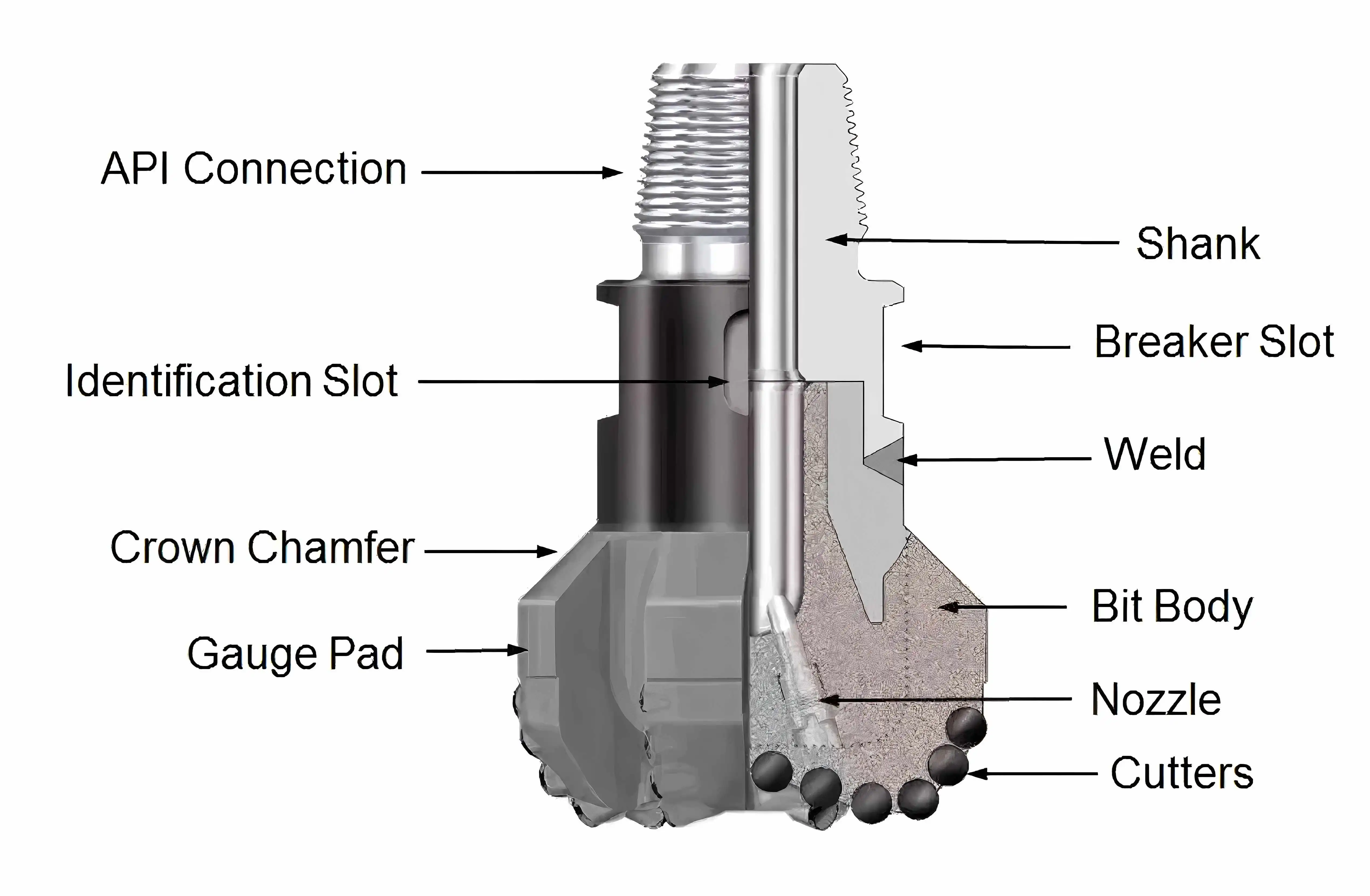

The bit is designed with five precision nozzles that optimize fluid circulation, ensuring effective removal of cuttings. This design actively washes away debris, preventing clogging and maintaining constant exposure of the cutters to fresh rock surfaces. By continuously clearing away cuttings, it not only preserves the drilling speed but also helps to extend the lifespan of the PDC cutters, improving overall drilling efficiency.

Reduced Torque and Wear

A major advantage of the concave profile is its ability to reduce overall torque during drilling. This limits the strain on drilling equipment and lessens the probability of mechanical failure in harsh environments. With less resistance and improved force transmission, wear on both the bit and the rig's drive system is minimized, reducing maintenance costs over time.

Enhanced Thermal Management

By improving fluid dynamics around the bit face, the concave design helps dissipate heat more effectively. This cooling effect protects the PDC cutters from thermal damage, maintaining structural integrity and cutting sharpness over longer operational periods.

What Rock Types Are Ideal for 153mm Coal Mine Concave Drill Bits?

Performance in Medium-Hard to Hard Rock Strata

The bit performs exceptionally in lithologies that include sandstone, shale, siltstone, and limestone. These formations are commonly encountered in coal mine strata, where drilling demands both aggressiveness and control. The PDC cutter grade 1308 is chosen specifically for its resilience in high-impact scenarios.

Adaptability in Stratified and Heterogeneous Formations

Coal seams are seldom found alone and are typically interspersed with different rock layers. The concave bit's design allows it to quickly adjust to variations in material density, enabling it to drill seamlessly through alternating strata. This adaptability eliminates the need for frequent tool changes, ensuring continuous drilling without interruptions, even in complex and heterogeneous geological formations.

Capable of Vertical and Deviated Drilling

While optimal in vertical drilling, the bit also supports deviated wellbores, which are increasingly used to reach otherwise inaccessible coal deposits. Its self-guiding concave structure stabilizes bit trajectory in both axial and angled directions, improving the precision of horizontal and directional drilling operations.

Optimized for Dry and Wet Conditions

Mining environments can vary greatly, ranging from dry, dusty conditions to water-saturated strata. This bit is designed to perform efficiently in both extremes, thanks to its advanced nozzle configuration and enhanced cutter protection. These features prevent slippage, ensuring consistent cutting performance and stability, whether the bit is operating in arid, dry environments or in wet, challenging, water-saturated formations.

Advantages of 3-Blade Wings vs. Traditional Designs in Mining Operations

Balanced Structure for Stable Operation

The 3-blade wing configuration ensures equal load distribution across all contact points. Unlike 2-blade bits that can wobble or 4-blade models that may over-complicate cutting paths, the tri-blade system achieves structural symmetry. This minimizes eccentric wear and promotes balanced bit rotation, crucial for maintaining borehole quality.

Increased Rate of Penetration (ROP)

Each blade wing of the bit is engineered to independently engage with the rock surface, enabling the use of more aggressive cutting angles while maintaining overall bit stability. This design results in an increased rate of penetration (ROP), significantly boosting drilling efficiency. Such enhanced performance makes the bit especially ideal for time-sensitive drilling projects, particularly in coalfields, where fast and effective penetration is crucial to meet project deadlines.

Improved Debris Channeling and Fluid Dynamics

Compared to more complex bit designs with additional blades, this bit features fewer blades, which results in larger spaces between each wing. This design allows for more efficient cuttings transport, enhancing the removal of debris. The improved flow dynamics support consistent fluid circulation and pressure, ensuring cleaner holes and reducing the need for extensive post-drilling cleanup, thus improving overall drilling efficiency.

Lower Energy Consumption

Efficiency in drilling goes beyond just speed; it also involves minimizing energy usage. The tri-wing bit design is specifically engineered to reduce the need for excessive rotational force and hydraulic power. This results in lower overall energy consumption, making the drilling process more cost-effective. Additionally, the reduced strain on equipment helps extend the service life of machinery, contributing to long-term operational savings.

Compatibility with Various Rig Types

The 153mm coal mine concave drill bit with 3 blade wings for rock drilling is adaptable to multiple drilling rigs due to its customizable connection types. This cross-platform compatibility simplifies logistics and enhances its usability in different mining operations.

Conclusion

The 153mm coal mine concave drill bit with 3 blade wings for rock drilling represents a fusion of modern engineering and practical field insight. With a design that maximizes rock engagement, promotes optimal debris clearance, and ensures structural stability, it serves as an essential asset in coal mine development and hard formation drilling. Its versatility across rock types, environmental conditions, and drilling orientations make it a reliable choice for efficient, high-performance operations.

For tailored consultation and expert advice, please contact us at hainaisen@hnsdrillbit.com.

References

1. "PDC Bit Design for Enhanced Performance in Coal Mining Environments," Journal of Mining Technology

2. "Comparative Analysis of Concave vs. Convex Bit Profiles in Hard Rock Drilling," Geological Engineering Reports

3. "The Impact of Nozzle Configuration on Drilling Fluid Dynamics," Mining Tools and Systems Review

4. "Optimizing Cutter Engagement in Multi-Blade Drill Bits," International Drilling Innovations Conference

5. "Evaluation of Bit Performance in Layered Geological Formations," Rock Mechanics Case Studies

6. "Structural Benefits of Asymmetric Bit Wing Designs," Advanced Mining Equipment Engineering Journal

VIEW MORESix Blade Wing Petroleum Drill Bit

VIEW MORESix Blade Wing Petroleum Drill Bit VIEW MORERock Roller Drill Bit

VIEW MORERock Roller Drill Bit VIEW MOREPDC Flat Top Sintered Drill Bit

VIEW MOREPDC Flat Top Sintered Drill Bit VIEW MORE113mm Three Wings PDC Arc Angle Drill Bit

VIEW MORE113mm Three Wings PDC Arc Angle Drill Bit VIEW MOREThree Blade Concave Drill Bit Api For Manganese Coal Mines

VIEW MOREThree Blade Concave Drill Bit Api For Manganese Coal Mines VIEW MOREFive Blade Wing Oil Drilling

VIEW MOREFive Blade Wing Oil Drilling VIEW MORE5 Blade Steel Body PDC Bit

VIEW MORE5 Blade Steel Body PDC Bit VIEW MOREThree Blades Rock Drill Bit

VIEW MOREThree Blades Rock Drill Bit