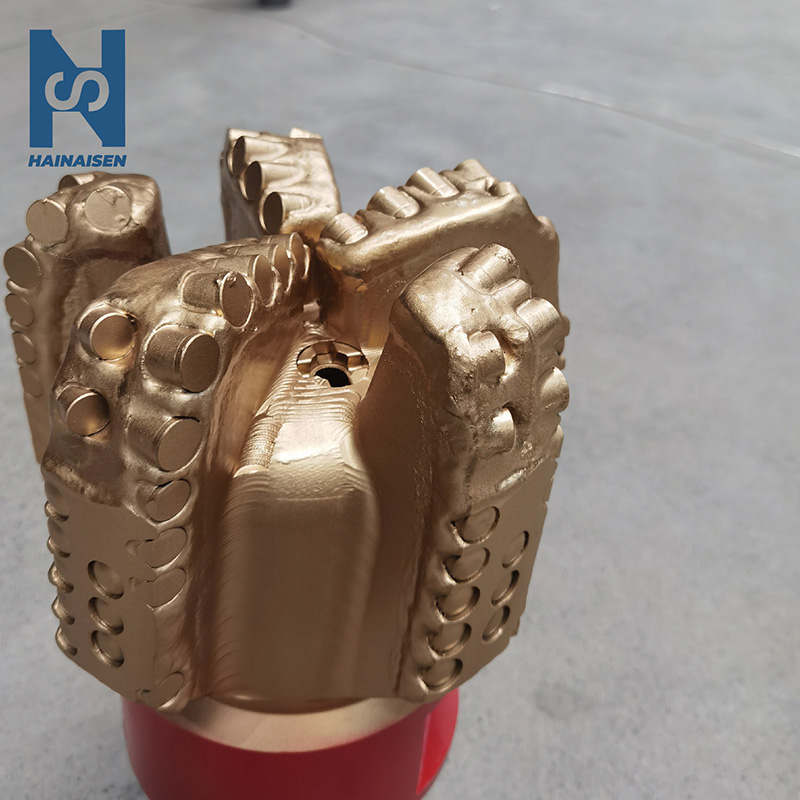

Five Blade Wing Oil Drilling

Bit size:12.25”(311mm)

Number of blade: 5

Number of nozzle: 7

PDC cutter size:13mm/16mm

Total number of PDC cutters : 109

Height of bit:510mm

Gauge length: 90mm

API Connection: 6 -5/8 REG.PIN

Net weight: 95KGS

- Product Description

Five Blade Wing Oil Drilling: Revolutionizing Efficiency in Oil Exploration

Are you looking to enhance your oil drilling operations? SHAANXI HAINAISEN INTELLIGENT EQUIPMENT MANUFACTURING CO.,LTD, a leading manufacturer of Five Blade Wing Oil Drilling equipment, offers cutting-edge solutions for the energy sector. Our innovative product tools combine advanced technology with durability, ensuring optimal performance in challenging environments.

Why Choose Our Five Blade Wing Oil Drilling Equipment?

- Superior drilling efficiency with five-blade design

- Enhanced stability and control during operation

- Increased penetration rates in various formations

- Reduced vibration for smoother drilling experience

- Longer lifespan compared to traditional drill bits

- Customizable options to meet specific project needs

Operating Parameters

| Parameter | Specification |

|---|---|

| Speed (R/min) | 60-250 |

| Drilling Pressure (KN) | 30-180 |

| Flow Rate (LPS) | 45-80 |

| Applicable Strata | Medium hardness, low compressive strength (e.g., shale, limestone, sandstone, gypsum) |

Applications

Our Five Blade Wing Oil Drilling equipment is versatile and suitable for various applications:

- Offshore and onshore oil exploration

- Natural gas drilling operations

- Geothermal energy projects

- Coal bed methane extraction

- Water well drilling

- Mineral exploration in medium-hard formations

Customization Services

At HAINAISEN, we understand that every drilling project is unique. Our team of experts works closely with clients to tailor product solutions to their specific requirements. We offer:

- Custom blade configurations

- Specialized coatings for harsh environments

- Adjustable cutting structures for different formations

- Integration with existing drilling systems

Material and Quality Control

Our product equipment is manufactured using premium-grade materials and undergoes rigorous quality control measures. We employ advanced testing techniques to ensure each product meets the highest industry standards.

Why Choose HAINAISEN?

- Over a decade of experience in drilling tool manufacturing

- State-of-the-art production facilities

- Dedicated R&D team constantly innovating

- Comprehensive after-sales support

- Competitive pricing without compromising quality

Shipment and Packaging

We place great emphasis on the safe and secure transportation of our product equipment. Our packaging is thoughtfully designed with durable materials and protective features to shield against potential damage during transit, ensuring that your tools arrive in pristine condition, ready for immediate use. We understand the importance of reliability in every stage of the process, and our commitment to robust packaging reflects our dedication to delivering quality products that meet your expectations from shipment to arrival.

Customer Feedback

Our clients consistently commend the exceptional performance and reliability of our product equipment. Across various industries, numerous users report significant boosts in productivity and notable reductions in downtime following their transition to HAINAISEN products. These testimonials underscore our commitment to delivering solutions that not only meet but exceed operational expectations, ensuring lasting value and trust for our partners.

After-Sales Service

We offer comprehensive after-sales support, including:

- Technical consultation

- On-site training

- Maintenance guidance

- Prompt resolution of any issues

Qualification Certifications

HAINAISEN holds a range of industry certifications, which serve as a testament to our unwavering commitment to quality and safety in product technology. These certifications validate that our solutions meet rigorous international standards, undergoing strict evaluations to ensure reliability, compliance, and performance. By upholding these benchmarks, we aim to provide our clients with confidence in our products’ integrity and our dedication to fostering safe, innovative technological advancements.

Frequently Asked Questions

Q: What makes product more efficient?

A: The five-blade design provides better stability and faster penetration rates.

Q: How long does a typical product bit last?

A: Lifespan varies based on conditions, but our bits generally outlast traditional options by 30-50%.

Q: Can your product equipment be used in hard rock formations?

A: While designed for medium hardness strata, we offer specialized versions for harder formations.

Q: Do you provide training for using product equipment?

A: Yes, we offer comprehensive training as part of our after-sales service.

Q: What's the lead time for custom product orders?

A: Lead times vary, but we typically fulfill custom orders within 4-6 weeks.

Contact Us

Ready to revolutionize your drilling operations with our Five Blade Wing Oil Drilling solutions? Contact us at hainaisen@hnsdrillbit.com for more information or to request a quote.

VIEW MORE30mm Half Blade Anchor Bit For Mine Coal Fields

VIEW MORE30mm Half Blade Anchor Bit For Mine Coal Fields VIEW MORE113mm PDC Arc Angle Drill Bit

VIEW MORE113mm PDC Arc Angle Drill Bit VIEW MORE3 Blades PDC Mining Bits

VIEW MORE3 Blades PDC Mining Bits VIEW MOREHard Alloy Scraper Drill Bit

VIEW MOREHard Alloy Scraper Drill Bit VIEW MORE5 Blades PDC Oil Bit

VIEW MORE5 Blades PDC Oil Bit VIEW MOREFour Blade Wing High Performance Petroleum Drill Bit

VIEW MOREFour Blade Wing High Performance Petroleum Drill Bit VIEW MOREPetroleum PDC Oil Drill Bit

VIEW MOREPetroleum PDC Oil Drill Bit VIEW MOREFive Blades Oil Well Drill Head

VIEW MOREFive Blades Oil Well Drill Head