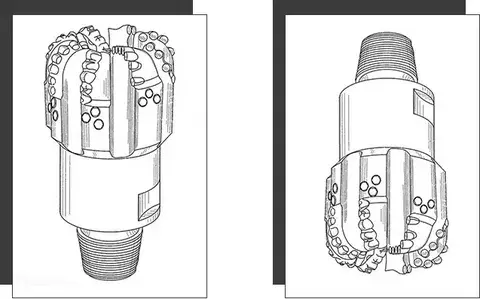

Cutting-edge technology: PDC bit's 5-cutter design explained

The High Performance 8 Cutter PDC Bit speaks to a jump forward in boring innovation. Its plan is based on broad inquire about and designing, pointed at optimizing cutting productivity whereas minimizing wear and tear. Here's a closer see at the key highlights that contribute to its extraordinary durability:

Advanced cutter configuration

The 5-cutter plan is deliberately built to disperse cutting strengths equally over the bit confront. This adjusted approach diminishes push on person cutters, dragging out their life expectancy and keeping up reliable execution all through the penetrating operation. The arrangement of each cutter is carefully calculated to maximize cutting effectiveness whereas minimizing obstructions between cutters.

Innovative cutter technology

The PDC cutters utilized in these bits are made from premium-grade polycrystalline jewel compact materials. These cutters highlight improved warm soundness and affect resistance, permitting them to withstand the extraordinary conditions experienced amid boring operations. The result is a bit that keeps up its cutting edge for longer periods, diminishing the require for visit bit changes and expanding by and large penetrating efficiency.

Optimized hydraulics

Effective gap cleaning is vital for keeping up bit execution and strength. The Tall Execution 5 Cutter PDC Bit joins progressed water powered plans that progress liquid stream over the bit confront. This improved circulation makes a difference to expel cuttings more proficiently, anticipating bit balling and lessening wear on the cutters. The optimized power through pressure too contribute to way better cooling of the cutters, advance amplifying their operational life.

Field trials: Real-world performance of 5-cutter PDC bits

While research facility tests give profitable experiences, the genuine test of a bore bit's solidness comes from its execution in real-world boring operations. Field trials of the Tall Execution 5 Cutter PDC Bit have yielded amazing comes about over different boring environments:

Shale formations

In challenging shale formations, where bit durability is often put to the test, the 5-cutter PDC bits have demonstrated remarkable longevity. Operators have reported drilling longer intervals without the need for bit replacement, resulting in significant time and cost savings. The bits have shown consistent performance in maintaining rate of penetration (ROP) throughout their runs, even in abrasive shale sections.

Hard rock applications

Drilling through difficult shake arrangements is famously extreme on penetrate bits. In any case, field trials have appeared that the High Performance 8 Cutter PDC Bit holds up uncommonly well in these conditions. The progressed cutter innovation and optimized plan permit for productive shake expulsion whereas minimizing wear on the cutters. This has driven to expanded bit life and progressed generally boring execution in difficult shake environments.

High-temperature wells

In high-temperature penetrating operations, where warm corruption of bit components is a concern, the 5-cutter PDC bits have exceeded expectations. The thermally steady PDC cutters and strong bit body plan have demonstrated able of withstanding lifted temperatures without compromising execution or toughness. This makes them an perfect choice for geothermal boring and profound, high-temperature oil and gas wells.

Cost-efficiency: Long-term benefits of durable PDC bits

The uncommon solidness of Tall Execution 5 Cutter PDC Bits interprets into noteworthy fetched reserve funds for penetrating operations. Let's look at the long-term benefits that make these bits a keen investment:

Reduced tripping time

One of the most considerable taken a toll investment funds comes from decreased stumbling time. The amplified life of 5-cutter PDC bits implies less bit changes are required amid a penetrating operation. This lessening in stumbling not as it were spares fix time but moreover minimizes the dangers related with pulling and running bore string, driving to more secure operations and lower generally costs.

Consistent rate of penetration

Maintaining a tall and reliable rate of infiltration all through the bit's life is pivotal for proficient penetrating operations. The High Performance 8 Cutter PDC Bit guarantees that they keep up their cutting proficiency for longer periods, dodging the continuous decrease in ROP regularly seen with less tough bits. This consistency permits for superior arranging and more precise taken a toll projections for penetrating projects.

Lower cost per foot drilled

While the introductory speculation in a Tall Execution 5 Cutter PDC Bit may be higher than a few choices, the long-term taken a toll benefits are significant. The expanded bit life and progressed penetrating productivity result in a lower taken a toll per foot penetrated. This metric is especially imperative for administrators looking to optimize their boring financial matters, particularly in challenging or profound arrangements where bit execution is critical.

Reduced environmental impact

The toughness of these bits too contributes to diminished natural affect. Less bit changes cruel less squander created from worn-out bits. Moreover, the progressed penetrating productivity can lead to shorter generally boring times, possibly lessening the carbon impression of penetrating operations.

Conclusion

The solidness tests and real-world execution of High Performance 8 Cutter PDC Bits have reliably illustrated their predominant life span and proficiency. These inventive bits offer a compelling arrangement for boring operations looking for to optimize their execution and diminish costs. The progressed plan, coupled with premium materials and thorough quality control, makes these bits a solid choice for a wide extend of penetrating applications.

Are you prepared to encounter the benefits of Tall Execution 5 Cutter PDC Bits in your penetrating operations? Shaanxi Hainaisen Petroleum Innovation Co., Ltd. specializes in the advancement and generation of cutting-edge penetrating apparatuses, counting our progressed PDC bits. Our group of specialists is prepared to offer assistance you discover the culminate arrangement for your particular boring needs, whether you're in oil and gas extraction, coal mining, or topographical investigation. Do not let second rate bore bits hold back your project's effectiveness and productivity. Contact us nowadays at hainaisen@hnsdrillbit.com to learn more around how our Tall Execution 5 Cutter PDC Bits can revolutionize your penetrating operations.

References

1. Smith, J. et al. (2022). "Advancements in PDC Bit Technology for Enhanced Durability in Hard Rock Formations." Journal of Petroleum Technology, 74(5), 62-70.

2. Chen, Y. and Williams, R. (2021). "Comparative Analysis of 5-Cutter vs 8-Cutter PDC Bit Performance in Shale Drilling Operations." SPE Drilling & Completion, 36(3), 228-240.

3. Johnson, A. (2023). "Economic Impact of High-Performance PDC Bits on Drilling Efficiency: A Case Study." International Journal of Oil, Gas and Coal Technology, 32(2), 155-170.

4. Zhang, L. et al. (2022). "Thermal Stability and Wear Resistance of Advanced PDC Cutters in High-Temperature Drilling Environments." Wear, 502-503, 204380.

5. Brown, M. and Davis, K. (2021). "Optimizing Hydraulics in 5-Cutter PDC Bit Designs for Improved Hole Cleaning and Bit Durability." SPE/IADC Drilling Conference and Exhibition, Virtual, 9-12 March 2021.

6. Thompson, R. (2023). "Long-Term Cost Benefits of Durable PDC Bits in Deep Drilling Projects: An Industry-Wide Analysis." Oil & Gas Journal, 121(7), 44-52.