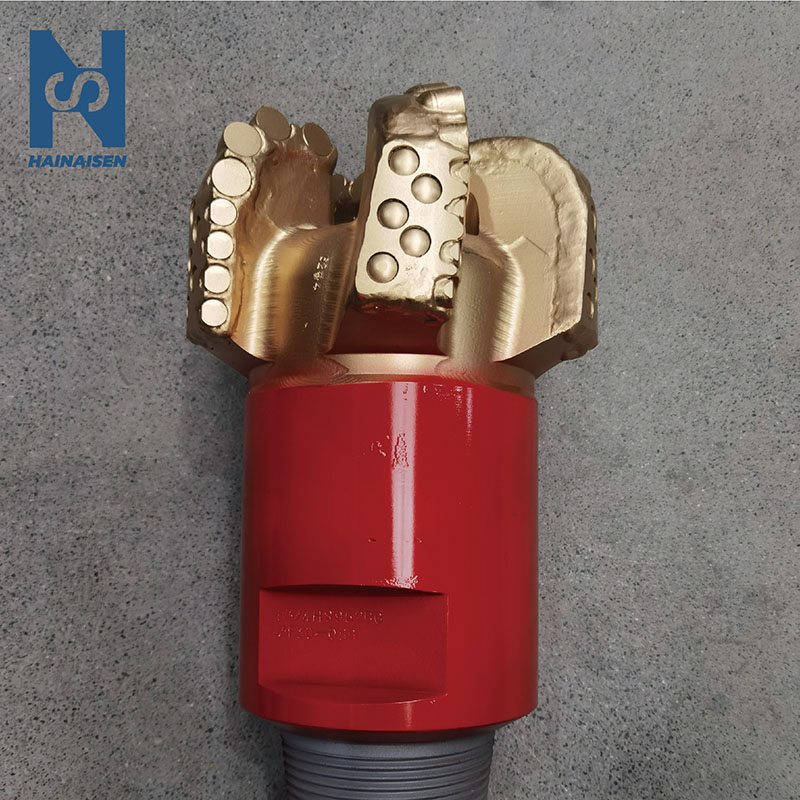

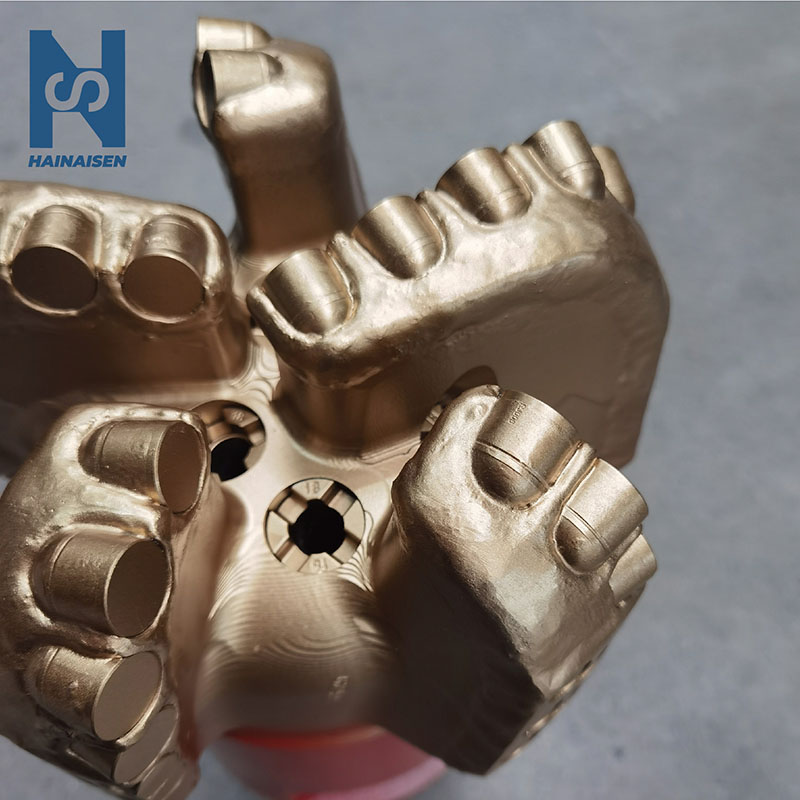

Five Blade PDC Drill Bit

Bit size: 5-5/8"

Number of blade:5

Number of nozzle:5

Connection: 3-1/2 REG.PIN (customized)

Total number of PDC cutter : 28

PDC Cutter size: 13mm/16mm

Net weight: 11.5kg

Applicable strata: Level 1-12

Minimum Order Quantity: 10 pieces

Price: To be negotiable

Packaging Details: customized

Delivery Time: 5-7 business days

Payment Terms: T/T, L/C

- Product Description

Five Blade PDC Drill Bit: High-Performance Drilling Solution

SHAANXI HAINAISEN INTELLIGENT EQUIPMENT MANUFACTURING CO.,LTD is a leading manufacturer and supplier of Five Blade PDC Drill Bits. Our advanced technology and innovative design make our PDC Drill Bit stand out in the industry. With superior wear resistance, improved cutting efficiency, and enhanced stability, our product is the ideal choice for oil & gas, mining, and water well drilling operations.

Why Choose Our Five Blade PDC Drill Bit?

- Exceptional durability and longevity

- Improved rate of penetration (ROP)

- Enhanced stability and reduced vibration

- Superior cutting efficiency in various formations

- Optimized hydraulics for better hole cleaning

- Customizable design to meet specific drilling requirements

Applications

Our product is versatile and suitable for a wide range of drilling applications:

- Oil and gas exploration and production

- Coal bed methane (CBM) drilling

- Shale gas extraction

- Hard rock mining operations

- Geothermal well drilling

- Water well drilling and exploration

- Geological core sampling

- Horizontal directional drilling (HDD)

Each application benefits from the product's unique design, offering improved performance and cost-effectiveness across various drilling conditions.

Customization Service

We understand that every drilling project has unique challenges. Our team of experts works closely with clients to design and manufacture custom products tailored to specific formation characteristics and drilling parameters. This ensures optimal performance and maximizes your drilling efficiency.

Material

Our Five Blade PDC Drill Bits are crafted using premium-grade materials:

- High-quality steel body for durability

- Advanced polycrystalline diamond compact (PDC) cutters

- Tungsten carbide matrix for enhanced wear resistance

Quality Control

At HAINAISEN, quality is our top priority. Every product undergoes rigorous testing and inspection:

- Strict raw material selection

- Advanced manufacturing processes

- Comprehensive performance testing

- Final quality inspection before shipment

Why Choose HAINAISEN

- Over 10 years of industry experience

- State-of-the-art manufacturing facility

- Dedicated R&D team for continuous innovation

- ISO 9001:2015 certified quality management system

- Excellent customer support and after-sales service

Shipment & Samples

At HAINAISEN, we understand that every client has unique logistical requirements, which is why we offer flexible shipping options tailored to your needs—whether for urgent deliveries or cost-effective solutions. Additionally, we provide sample products upon request, allowing you to evaluate their performance, durability, and suitability for your projects firsthand. Simply reach out to our team to discuss your shipping preferences and sample needs; we’ll ensure seamless coordination from request to delivery, ensuring you have the flexibility and insights needed to make informed decisions about our solutions.

Packaging and Transportation

Our products are carefully packaged to ensure safe transportation:

- Custom wooden crates or steel boxes

- Protective wrapping to prevent damage

- Secure labeling for easy identification

Transaction Feedback

We value customer satisfaction and continuously improve based on feedback. Our clients consistently praise the performance and reliability of our products.

After-Sales Service

Our commitment doesn't end with the sale. We provide comprehensive after-sales support:

- Technical guidance for optimal bit selection

- Performance analysis and optimization

- Prompt resolution of any issues

Qualification Certification

HAINAISEN holds various certifications, including ISO 9001:2015, demonstrating our commitment to quality and industry standards.

FAQ

Q: What is the lifespan of a product?

A: The lifespan varies depending on formation and drilling conditions. Typically, it can last 2-3 times longer than conventional bits.

Q: Can your product be used in high-temperature environments?

A: Yes, our bits are designed to withstand high temperatures encountered in deep drilling operations.

Q: Do you offer training on proper use and maintenance?

A: Absolutely. We provide comprehensive training and support to ensure optimal performance.

Q: What is the minimum order quantity for custom products?

A: We can accommodate various order sizes. Please contact us for specific requirements.

Q: How long does it take to manufacture a custom product?

A: Typically, 2-4 weeks, depending on complexity and current production schedule.

Contact Us

For inquiries or to discuss your Five Blade PDC Drill Bit needs, please email us at hainaisen@hnsdrillbit.com.

VIEW MOREPDC Rock Drill Bit

VIEW MOREPDC Rock Drill Bit VIEW MOREDiamond PDC Drill Bit

VIEW MOREDiamond PDC Drill Bit VIEW MOREFive Wing PDC Bit For Hard Rock Drilling

VIEW MOREFive Wing PDC Bit For Hard Rock Drilling VIEW MORE5 Blades Steel Body High Performance PDC Rock Drill Bits

VIEW MORE5 Blades Steel Body High Performance PDC Rock Drill Bits VIEW MOREHigh Performance 5 Cutter PDC Bit

VIEW MOREHigh Performance 5 Cutter PDC Bit VIEW MORE5 Blade Matrix Body PDC Drill Bits

VIEW MORE5 Blade Matrix Body PDC Drill Bits VIEW MORESteel Body PDC Bit 4 Blades

VIEW MORESteel Body PDC Bit 4 Blades VIEW MOREFour Blade PDC Drill Bit

VIEW MOREFour Blade PDC Drill Bit