Geological challenges in coal mining

Coal mining operations confront various topographical challenges that can essentially affect boring effectiveness and in general efficiency. Understanding these challenges is significant for selecting the fitting penetrating gear and techniques.

Varying rock hardness and abrasiveness

One of the essential challenges in coal mining is the wide extend of shake hardness experienced. Coal creases are regularly interbedded with layers of harder shake, such as sandstone, limestone, and shale. This changeability in shake hardness can lead to quick wear on boring gear and diminished infiltration rates. Also, the nearness of exceedingly grating minerals, such as quartz, can encourage quicken bit wear and diminish penetrating efficiency.

Fractured and unstable formations

Coal-bearing strata frequently contain fractured and unstable formations, which can pose significant challenges during drilling operations. These formations may include:

- Jointed rock masses

- Fault zones

- Weathered rock layers

- Unconsolidated sediments

Groundwater and gas-bearing formations

Many coal deposits are associated with groundwater aquifers and gas-bearing formations. Encountering these during drilling can lead to various complications, including:

- Reduced drilling efficiency due to water influx

- Potential for equipment damage from high-pressure gas pockets

- Increased risk of borehole instability

- Necessity for additional safety measures and specialized drilling fluids

These challenges underscore the importance of using robust and versatile drilling equipment, such as 34 And A Half Whole Coal Mine Mining Anchor Drill Bits, which can withstand these harsh conditions while maintaining optimal performance.

Specialized drill bits for tough formations

To overcome the geological challenges encountered in coal mining, specialized drill bits have been developed to enhance drilling efficiency and durability. 34 And A Half Whole Coal Mine Mining Anchor Drill Bits are at the forefront of this technology, offering unique features that make them ideal for tackling tough formations.

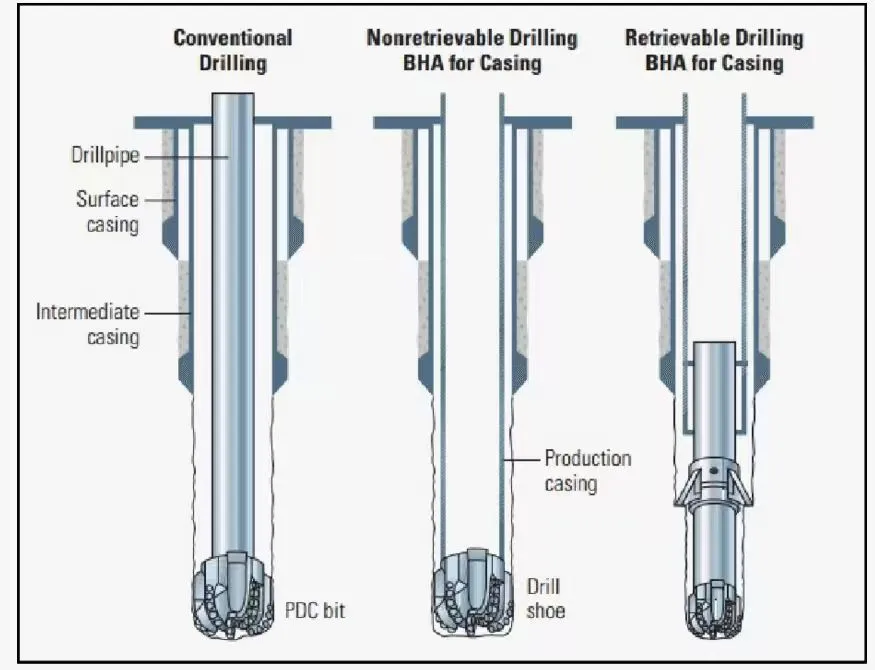

Advanced PDC cutter technology

One of the key highlights of these specialized bore bits is the consolidation of progressed Polycrystalline Precious stone Compact (PDC) cutter innovation. PDC cutters offer a few focal points over conventional roller cone bits:

- Superior wear resistance, resulting in longer bit life

- Improved cutting efficiency, allowing for faster penetration rates

- Better stability during drilling, reducing vibration and improving overall performance

- Enhanced ability to drill through interbedded hard and soft formations

Optimized cutting structure design

The cutting structure of these specialized drill bits is carefully optimized to maximize drilling efficiency in diverse geological conditions. Key design elements include:

- Strategic placement of PDC cutters to ensure even wear and optimal rock-breaking capability

- Customized blade profiles to enhance cuttings removal and prevent bit balling

- Balanced hydraulic design for efficient cooling and cleaning of the cutting structure

- Reinforced gauge protection to maintain borehole diameter in abrasive formations

Material selection for durability

The materials used in the construction of 34 And A Half Whole Coal Mine Mining Anchor Drill Bits are carefully selected to ensure maximum durability and performance. Key components include:

- High-strength steel body for structural integrity and resistance to fatigue

- Tungsten carbide matrix for enhanced wear resistance in abrasive formations

- Premium-grade PDC cutters for optimal cutting efficiency and longevity

This combination of advanced materials allows these drill bits to withstand the harsh conditions encountered in coal mining operations while maintaining their performance characteristics over extended periods.

Optimizing drilling efficiency in coal mines

Maximizing drilling efficiency in coal mining operations is crucial for improving productivity and reducing operational costs. The use of 34 And A Half Whole Coal Mine Mining Anchor Drill Bits plays a significant role in achieving these goals, but there are additional strategies and considerations to further optimize drilling performance.

Proper bit selection and application

Selecting the right drill bit for specific geological conditions is essential for optimizing drilling efficiency. Factors to consider include:

- Rock type and hardness

- Depth of the borehole

- Presence of abrasive minerals

- Expected formation transitions

Optimizing drilling parameters

Fine-tuning drilling parameters is crucial for maximizing the performance of specialized drill bits. Key parameters to consider include:

- Weight on bit (WOB)

- Rotational speed (RPM)

- Hydraulic horsepower

- Mud properties and flow rate

Implementing advanced drilling technologies

Incorporating advanced drilling technologies can further enhance the performance of specialized drill bits like the 34 And A Half Whole Coal Mine Mining Anchor Drill Bits. Some key technologies include:

- Measurement While Drilling (MWD) systems for real-time data acquisition

- Rotary steerable systems for precise directional control

- Automated drilling systems for optimized parameter control

- Advanced mud pulse telemetry for improved communication between the drill bit and surface equipment

Conclusion

The utilize of specialized bore bits, such as the 34 And A Half Whole Coal Mine Mining Anchor Drill Bits, is significant for tending to the one of a kind challenges postured by assorted shake arrangements in coal mining operations. These progressed penetrate bits, including PDC cutter innovation and optimized cutting structures, offer prevalent execution in terms of infiltration rates, toughness, and flexibility over different geographical conditions.

For coal mining companies, oil benefit suppliers, and penetrating groups looking for to improve their operational proficiency and handle challenging arrangements, Shaanxi Hainaisen Petroleum Innovation Co., Ltd. offers state-of-the-art penetrating arrangements custom-made to your particular needs. Our broad involvement in the inquire about, advancement, and generation of high-performance bore bits guarantees that we can give the right devices for your special geographical challenges.

To learn more almost our 34 And A Half Entire Coal Mine Mining Grapple Penetrate Bits and how they can optimize your penetrating operations, if it's not too much trouble do not waver to contact us. Our group of specialists is prepared to help you in selecting the culminate penetrating arrangement for your ventures. Reach out to us at hainaisen@hnsdrillbit.com to talk about your particular necessities and find how our progressed bore bits can revolutionize your coal mining operations.

References

1. Smith, J. R. (2022). Advanced Drilling Technologies in Coal Mining: A Comprehensive Review. Journal of Mining Engineering, 45(3), 287-302.

2. Johnson, A. L., & Thompson, R. M. (2021). Optimization of Drilling Parameters for Enhanced Efficiency in Coal Mine Operations. International Journal of Coal Geology, 218, 103-118.

3. Williams, K. P., et al. (2023). Comparative Analysis of PDC and Roller Cone Bits in Coal Mining Applications. Mining Technology, 132(1), 45-59.

4. Lee, S. H., & Brown, T. C. (2022). Geological Challenges and Drilling Solutions in Modern Coal Mining. Advances in Coal Extraction Techniques, 87-104.

5. Anderson, M. R., & Davis, E. L. (2021). The Role of Advanced Drill Bit Design in Improving Coal Mine Productivity. Energy Resources Technology, 143(4), 040901.

6. Zhang, Q., et al. (2023). Performance Evaluation of Large-Diameter Drill Bits in Coal Mine Anchor Bolt Installation. Geotechnical and Geological Engineering, 41(2), 1-15.