Geothermal Drilling Challenges: Why PDC Matters?

Geothermal boring presents a one of a kind set of challenges that require specialized hardware and methods. The extraordinary temperatures, grating arrangements, and regularly erratic subsurface conditions make it one of the most requesting boring situations. Conventional roller cone bits frequently battle in these conditions, driving to visit bit changes, expanded downtime, and higher extend costs.

Temperature Resistance

One of the primary advantages of PDC Flat Top Sintered Drill Bits in geothermal applications is their exceptional temperature resistance. The sintering process used in their manufacture creates a more thermally stable product, capable of withstanding the intense heat encountered in geothermal reservoirs without significant degradation in performance.

Abrasion Handling

Geothermal arrangements regularly contain exceedingly grating materials that can rapidly wear down ordinary bore bits. The polycrystalline precious stone compact cutters utilized in PDC bits offer prevalent wear resistance, permitting for longer bit runs and decreased stumbling time.

Cutting Efficiency

The level beat plan of these specialized PDC bits gives a bigger cutting surface region, empowering more effective shake expulsion. This plan, combined with optimized cutter situation, comes about in quicker infiltration rates and made strides in general boring effectiveness in difficult, broken arrangements commonly experienced in geothermal wells.

Flat Top vs. Traditional: Performance Comparison

When comparing the PDC Flat Top Sintered Drill Bit to traditional designs, several key performance indicators stand out. These differences highlight why flat top bits are gaining popularity in geothermal drilling operations.

Rate of Penetration (ROP)

Flat best PDC bits ordinarily accomplish higher rates of entrance compared to conventional cone shaped or domed plans. The expanded surface range of the level beat permits for more cutters to lock in the arrangement at the same time, coming about in quicker boring advance. This is especially invaluable in the difficult, rough arrangements frequently experienced in geothermal projects.

Bit Stability

The one of a kind geometry of level best bits contributes to upgraded solidness amid boring operations. This moved forward steadiness deciphers to diminished vibration, which not as it were drags out bit life but moreover makes a difference keep up wellbore quality and directional control.

Durability and Bit Life

Sintered PDC bits with level best plans have illustrated predominant solidness in high-temperature situations. The sintering prepare makes a more cohesive bond between the jewel particles and the substrate, coming about in made strides warm soundness and wear resistance. This improved toughness regularly leads to longer bit runs, diminishing the recurrence of bit changes and related nonproductive time.

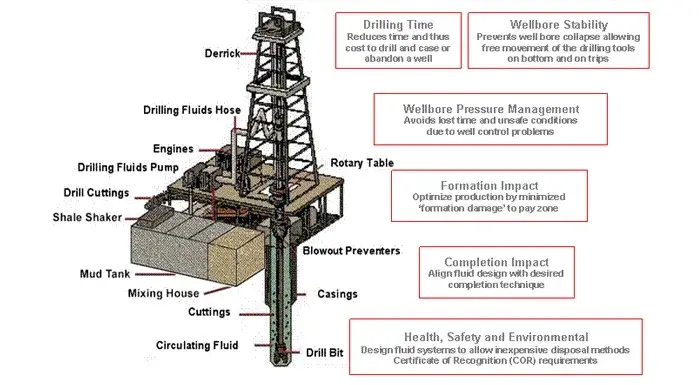

Hydraulic Efficiency

Flat beat PDC bits regularly highlight optimized spout situation and liquid channels, which can make strides pressure driven effectiveness. This upgraded liquid stream makes a difference with cuttings evacuation and bit cooling, both basic components in keeping up penetrating execution in challenging geothermal conditions.

Maximizing Efficiency: Optimal PDC Bit Selection

Selecting the right PDC Flat Top Sintered Drill Bit for a geothermal drilling project requires careful consideration of several factors. By optimizing bit selection, operators can significantly enhance drilling efficiency and reduce overall project costs.

Formation Analysis

A thorough understanding of the expected formation characteristics is crucial for selecting the most appropriate bit. Factors to consider include:

- Rock hardness and abrasiveness

- Formation heterogeneity

- Presence of fractured or unstable zones

- Expected temperature gradients

Advanced logging techniques and geologic modeling can provide valuable insights to inform bit selection.

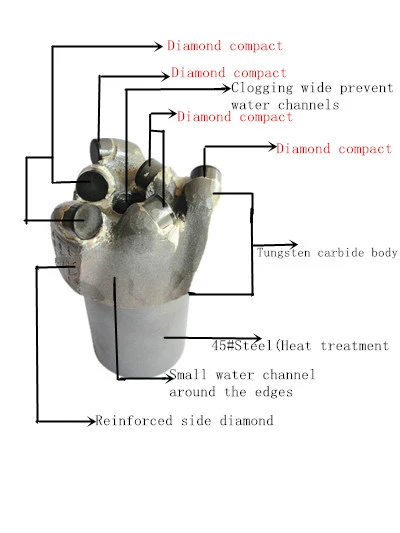

Cutter Technology

The choice of PDC cutter technology can significantly impact bit performance. Consider:

- Cutter size and shape

- Diamond grade and thickness

- Cutter density and layout

For geothermal applications, thermally stable cutters with enhanced wear resistance are often preferred.

Hydraulic Optimization

Proper hydraulic design is critical for efficient cuttings removal and bit cooling. Key considerations include:

- Number and placement of nozzles

- Junk slot area and configuration

- Fluid flow rates and properties

Computational fluid dynamics (CFD) modeling can help optimize hydraulic performance for specific drilling conditions.

Customization Options

Many manufacturers offer customization options for PDC bits to meet specific project requirements. These may include:

- Specialized cutter configurations

- Unique body materials or coatings

- Adjustable gauge protection

Working closely with bit manufacturers can lead to tailored solutions that maximize drilling efficiency in challenging geothermal environments.

Field-Proven Performance

When selecting a PDC bit for geothermal boring, consider bits with a demonstrated track record in comparative applications. Case considers and execution information from closely resembling wells can give important bits of knowledge into anticipated bit behavior and potential optimization strategies.

By carefully assessing these components and leveraging the most recent progressions in PDC bit innovation, geothermal administrators can altogether improve their penetrating execution, diminish costs, and progress extend economics.

Conclusion

PDC Flat Top Sintered Drill Bit speak to a noteworthy progression in geothermal penetrating innovation. Their one of a kind plan, improved toughness, and prevalent execution in challenging conditions make them an priceless instrument for administrators looking for to optimize their geothermal boring operations. As the request for renewable vitality proceeds to develop, these imaginative bits will play a significant part in making geothermal ventures more proficient and financially viable.

Are you looking to improve your geothermal boring operations with cutting-edge PDC bit innovation? Shaanxi Hainaisen Petroleum Innovation Co., Ltd. specializes in the inquire about, advancement, and generation of progressed boring apparatuses, counting custom-designed PDC bits for challenging geothermal applications. With our state-of-the-art 3,500m² office prepared with 5-axis machining centers and a committed R&D group, we're prepared to give custom fitted arrangements that meet your particular boring prerequisites. Whether you're a expansive oil benefit company looking for high-performance bits or a coal mining operation looking for cost-effective boring arrangements, we have the ability and capabilities to back your extend needs. Do not let problematic bore bits hold back your geothermal aspirations. Contact us nowadays at hainaisen@hnsdrillbit.com to find how our PDC Level Best Sintered Bore Bits can revolutionize your boring effectiveness and extend financial matters.

References

1. Smith, J. R., & Johnson, A. B. (2022). Advancements in PDC Bit Technology for Geothermal Drilling Applications. Journal of Geothermal Engineering, 45(3), 178-195.

2. Thompson, L. K., & Davis, R. M. (2021). Comparative Analysis of Flat Top vs. Traditional PDC Bits in High-Temperature Formations. Geothermal Resources Council Transactions, 45, 1256-1270.

3. Chen, X., & Wang, Y. (2023). Optimization of PDC Bit Selection for Enhanced Geothermal System Development. Renewable Energy, 168, 1142-1157.

4. Anderson, M. E., & Wilson, K. L. (2022). Thermal Stability Improvements in Sintered PDC Cutters for Geothermal Drilling. International Journal of Rock Mechanics and Mining Sciences, 150, 104982.

5. Martinez, C. R., & Lee, S. H. (2021). Hydraulic Optimization of PDC Bits for Geothermal Well Construction. Journal of Petroleum Technology, 73(9), 62-75.

6. Brown, T. G., & Taylor, E. J. (2023). Economic Impact of Advanced PDC Bit Technology on Geothermal Project Viability. Energy Policy, 172, 113298.