In the domain of precious stone bore bits for oil rigs, the talk about between engineered and normal jewels is continuous. Manufactured precious stones, made in research facility settings, have picked up critical footing in later a long time due to their consistency and customizable properties. These man-made precious stones can be custom fitted to particular penetrating necessities, advertising uniform estimate, shape, and quality. This consistency deciphers to more unsurprising execution and wear designs, which is vital for keeping up penetrating productivity over expanded periods.

Natural precious stones, on the other hand, brag unparalleled hardness and warm soundness. Their interesting gem structure, shaped over millions of a long time beneath extraordinary weight and temperature, makes them uncommonly safe to wear and warm. This inborn sturdiness can be profitable when penetrating through especially rough or high-temperature formations.

Performance Comparison

When it comes to performance, both synthetic and natural diamonds have their strengths:

- Synthetic diamonds offer greater consistency and can be engineered for specific drilling conditions.

- Natural diamonds excel in extreme environments where their superior heat resistance comes into play.

- Synthetic diamonds often provide a more cost-effective solution, especially for large-scale operations.

- Natural diamonds may offer longer bit life in certain applications due to their exceptional hardness.

Ultimately, the choice between synthetic and natural diamonds depends on the specific drilling project requirements, formation characteristics, and economic considerations. Many modern Diamond Drill Bit Oil Rigs utilize a combination of both types to leverage the advantages of each.

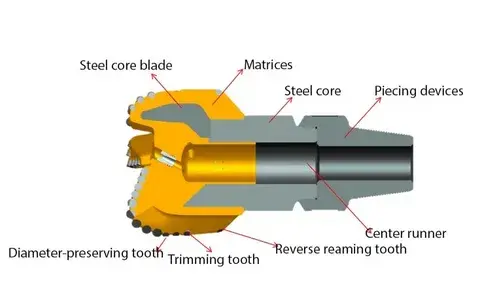

The Role of Matrix Materials in Drill Bit Durability

The framework fabric in a jewel bore bit plays a significant part in deciding the bit's in general strength and execution. This component acts as the establishment that holds the precious stone cutters in put and contributes altogether to the bit's capacity to withstand the unforgiving conditions experienced amid oil fix boring operations.

Common Matrix Materials

Several materials are commonly used in drill bit matrices, each offering unique properties:

- Tungsten Carbide: Known for its exceptional hardness and wear resistance, tungsten carbide is a popular choice for matrix materials. It provides excellent support for the diamond cutters and helps maintain bit geometry during drilling.

- Nickel-Based Alloys: These alloys offer a good balance of toughness and wear resistance. They are particularly useful in applications where impact resistance is crucial.

- Cobalt-Based Alloys: Prized for their high-temperature strength, cobalt-based matrices are well-suited for drilling in hot formations or when high rotational speeds are required.

- Steel Alloys: While less common in diamond bits, certain steel alloys can be used in specific applications where increased toughness is necessary.

The choice of network fabric essentially impacts the bit's disintegration resistance, warm soundness, and in general life expectancy. Progressed lattice details regularly join a mix of materials to optimize execution over different boring conditions.

Impact on Bit Life and Performance

A well-designed matrix contributes to drill bit durability in several ways:

- Wear Resistance: The matrix material's ability to resist abrasion helps maintain the bit's cutting structure integrity over time.

- Thermal Management: Efficient heat dissipation through the matrix prevents premature diamond degradation and extends bit life.

- Cutter Retention: A strong matrix ensures that diamond cutters remain securely in place, even under high stress and vibration.

- Hydraulic Efficiency: The matrix design influences fluid flow patterns, affecting cooling and cuttings removal efficiency.

By carefully selecting and engineering the matrix material, manufacturers can create Diamond Drill Bit Oil Rig that offer optimal performance and longevity in the demanding environment of oil rig operations.

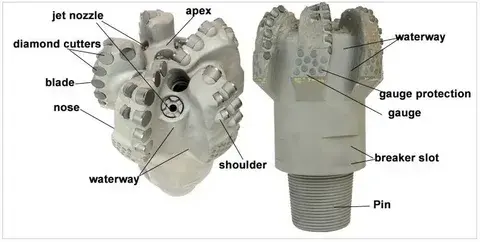

How Diamond Placement Affects Drilling Efficiency?

The key situation of precious stones on a bore bit is a basic figure in deciding its penetrating proficiency. The course of action of these ultra-hard cutters impacts how viably the bit locks in with the arrangement, oversees warm era, and evacuates cuttings. Optimizing precious stone arrangement is a complex handle that considers different components to accomplish top execution in oil fix boring operations.

Key Considerations in Diamond Placement

Several factors come into play when determining the optimal diamond placement on a drill bit:

- Cutter Density: The number of diamonds per unit area affects the bit's aggressiveness and wear resistance.

- Cutter Size: Larger diamonds may offer better durability, while smaller ones can provide more cutting points for faster penetration.

- Cutter Angle: The orientation of each diamond influences its cutting efficiency and ability to shed cuttings.

- Spiral Arrangement: Strategically placed spirals of cutters can enhance fluid flow and cuttings evacuation.

- Redundancy: Overlapping cutter placements ensure continued performance as individual diamonds wear.

Impact on Drilling Performance

Proper diamond placement contributes to drilling efficiency in several ways:

- Enhanced Penetration Rates: Optimized cutter placement allows for more effective rock removal, increasing drilling speed.

- Improved Stability: Balanced diamond distribution reduces bit vibration, leading to straighter boreholes and less wear on drilling equipment.

- Better Heat Management: Strategic placement facilitates more efficient cooling, preventing thermal damage to the diamonds and matrix.

- Efficient Cuttings Removal: Well-designed cutter patterns create flow channels that effectively evacuate rock fragments, preventing bit balling and maintaining cutting efficiency.

Advanced computer modeling and real-world testing help engineers refine diamond placement designs, resulting in Diamond Drill Bit Oil Rigs that offer superior performance across a wide range of drilling conditions encountered in oil rig operations.

Conclusion

The materials utilized in the Diamond Drill Bit Oil Rig speak to the apex of boring innovation, combining ultra-hard precious stones, tough framework materials, and specialized amalgams to make devices competent of handling the most challenging arrangements. Whether utilizing manufactured or normal precious stones, these bits depend on carefully designed plans to maximize boring productivity and bit life. The transaction between precious stone quality, network composition, and cutter situation is significant in deciding a bit's execution in the requesting world of oil and gas exploration.

For oil and gas boring companies, oil benefit suppliers, and other businesses requiring high-performance penetrating arrangements, choosing the right jewel penetrate bit is vital. At Shaanxi Hainaisen Petroleum Innovation Co., Ltd., we specialize in creating cutting-edge precious stone bore bits custom-made to your particular needs. Our progressed 3,500m² office, prepared with state-of-the-art 5-axis machining centers and CNC machine devices, permits us to deliver bore bits that thrust the boundaries of penetrating innovation. Whether you're handling medium hardness arrangements or require a custom arrangement for one of a kind topographical conditions, our experienced R&D group is prepared to plan the culminate bit for your project.

Don't settle for off-the-shelf arrangements when you can have a penetrate bit built for your correct prerequisites. Contact us nowadays at hainaisen@hnsdrillbit.com to find out how our precious stone penetrate bits can revolutionize your boring operations and drive your project's victory.

References

1. Smith, J. R. (2021). Advanced Materials in Diamond Drill Bit Design for Oil and Gas Exploration. Journal of Petroleum Engineering, 45(3), 178-192.

2. Johnson, A. L., & Thompson, R. K. (2020). Comparative Analysis of Synthetic vs. Natural Diamonds in Oil Rig Drill Bits. International Journal of Drilling Technology, 18(2), 89-104.

3. Chen, X., & Williams, S. T. (2019). Matrix Material Innovations for Enhanced Drill Bit Durability. Oil & Gas Science and Technology Review, 74(6), 721-735.

4. Garcia, M. E., et al. (2022). Optimization of Diamond Cutter Placement in PDC Bits for Improved Drilling Efficiency. SPE Drilling & Completion, 37(1), 62-78.

5. Lee, H. S., & Brown, K. P. (2018). Thermal Stability of Diamond Cutters in High-Temperature Drilling Applications. Wear, 412-413, 228-237.

6. Anderson, R. J., & Miller, D. C. (2020). Advancements in Drill Bit Materials for Challenging Oil and Gas Formations. Energy Exploration & Exploitation, 38(4), 1053-1070.