Heat Generation in Deep Drilling Operations

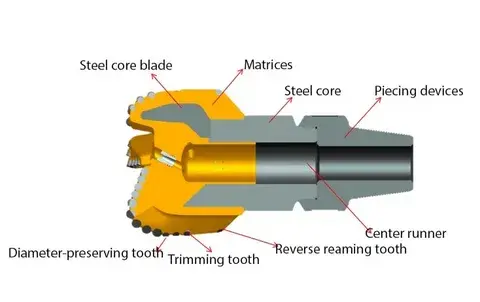

During deep drilling operations, Diamond Drill Bits For Oil Rigs encounter significant heat generation due to several factors:

Friction and Mechanical Energy

The essential source of warm in penetrating operations is grinding between the bore bit and the shake arrangement. As the bit turns and cuts through different strata, mechanical vitality is changed over into warm vitality. This handle is heightens in harder arrangements, where more drive is required to enter the shake, coming about in higher temperatures at the bit-rock interface.

Hydraulic Energy Dissipation

Drilling liquids, or muds, are pumped through the bore string to cool the bit and expel cuttings. Be that as it may, the high-pressure stream of these liquids too contributes to warm era through water powered vitality scattering. As the liquid experiences resistance in the borehole and bit spouts, a few of its vitality is changed over to warm, assist hoisting temperatures in the penetrating zone.

Formation Temperature

As boring profundity increments, so does the encompassing temperature of the encompassing shake arrangements. This geothermal angle can altogether affect the generally warm environment in which the bore bit works. In a few profound wells, arrangement temperatures can surpass 150°C (302°F), posturing extra challenges for bit warm management.

Impact on Bit Performance

Excessive heat can have detrimental effects on diamond drill bits:

- Thermal degradation of diamond cutters

- Accelerated wear of the bit body and matrix material

- Reduced cutting efficiency due to thermal softening of the bit structure

- Increased risk of bit failure or damage

To mitigate these issues, drill bit manufacturers focus on developing advanced materials and designs that can withstand high temperatures while maintaining optimal cutting performance.

Cooling Systems: Extending Bit Lifespan

Effective cooling systems are essential for maximizing the lifespan and performance of Diamond Drill Bits For Oil Rigs operations. These systems play a vital role in managing the thermal dynamics that affect bit integrity and cutting efficiency.

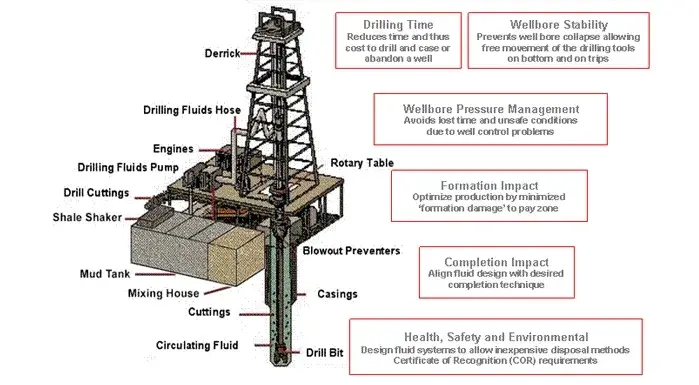

Drilling Fluid Circulation

The primary cooling mechanism for drill bits is the circulation of drilling fluids. These fluids serve multiple purposes:

- Heat dissipation from the bit and bottom hole assembly

- Lubrication of the bit-rock interface to reduce friction

- Transportation of rock cuttings to the surface

- Pressure control in the wellbore

Advanced boring liquid details are outlined to optimize warm exchange properties whereas keeping up other basic capacities such as wellbore solidness and cutting suspension.

Nozzle Design and Placement

The plan and vital arrangement of spouts on the penetrate bit play a significant part in cooling productivity. Advanced precious stone bore bits include optimized spout setups that coordinate cooling liquid accurately where it's required most:

- Cutter face cooling to prevent thermal degradation

- Junk slot flushing to remove cuttings and prevent bit balling

- Gauge area cooling to maintain bit diameter and stability

Computational liquid flow (CFD) reenactments are frequently utilized to refine spout plans for most extreme cooling viability over different boring conditions.

Thermal Stabilizers

Some advanced diamond drill bits incorporate thermal stabilizers within their structure. These components are designed to:

- Absorb and redistribute heat more evenly across the bit body

- Reduce thermal stress concentrations in critical areas

- Enhance overall thermal stability during prolonged drilling operations

Thermal stabilizers can be particularly beneficial in high-temperature formations or when drilling with limited fluid circulation.

Bit Design for Enhanced Cooling

The overall design of diamond drill bits has evolved to incorporate features that facilitate better cooling:

- Increased surface area for heat dissipation

- Optimized fluid flow paths to maximize cooling efficiency

- Integration of thermally conductive materials in strategic locations

- Reduced contact area between the bit and formation to minimize heat generation

These design enhancements work in concert with cooling systems to extend bit lifespan and maintain cutting efficiency under challenging thermal conditions.

Thermal Stress: Balancing Hardness and Toughness

Managing warm push is a basic perspective of precious stone bore bit plan and operation, especially for those utilized in oil fix situations. The challenge lies in adjusting the hardness required for effective cutting with the durability required to withstand warm variances and mechanical loads.

Material Selection and Engineering

The choice of materials for Diamond Drill Bits For Oil Rigs is crucial in addressing thermal stress:

- Synthetic diamonds: Engineered to withstand high temperatures and maintain cutting efficiency

- Tungsten carbide matrix: Provides a balance of hardness and thermal conductivity

- Advanced binder materials: Enhance overall bit toughness and thermal stability

Material scientists continually work on developing new composites and alloys that offer improved thermal resistance without compromising cutting performance.

Thermal Expansion Management

Differential thermal expansion between various components of the drill bit can lead to internal stresses and potential failure. To address this:

- Careful matching of thermal expansion coefficients among bit components

- Design of interfaces and joints to accommodate thermal expansion

- Use of flexible elements to absorb thermal stresses in critical areas

These strategies help maintain bit integrity across a wide range of operating temperatures encountered in deep drilling operations.

Stress Distribution Optimization

Advanced modeling techniques, such as finite element analysis (FEA), are employed to optimize stress distribution within diamond drill bits:

- Identifying and reinforcing high-stress areas

- Designing stress-relief features to prevent crack propagation

- Balancing load distribution across cutting elements

By carefully managing stress concentrations, engineers can create drill bits that are more resilient to thermal and mechanical loads encountered during drilling.

Thermal Fatigue Resistance

Repeated heating and cooling cycles can lead to thermal fatigue in drill bit components. To enhance resistance to this phenomenon:

- Development of materials with high thermal cycling tolerance

- Implementation of gradual cooling strategies during bit manufacturing

- Design of thermal barriers to protect sensitive components

These measures help extend the operational life of diamond drill bits in thermally demanding environments.

Adaptive Drilling Parameters

While much of thermal stress management is addressed through bit design and materials, operational practices also play a crucial role:

- Real-time monitoring of downhole temperatures

- Adjustment of drilling parameters (speed, weight on bit, fluid flow) to manage heat generation

- Implementation of cooling cycles during extended drilling operations

By adjusting penetrating parameters based on warm conditions, administrators can minimize warm push on the bit and optimize its execution and longevity.

Conclusion

nderstanding and overseeing the warm flow that influence Diamond Drill Bits For Oil Rigs is basic for fruitful oil fix operations. From warm era to cooling frameworks and warm push administration, each perspective plays a significant part in bit execution and life span. As penetrating operations proceed to thrust the boundaries of profundity and complexity, the significance of warm contemplations in bore bit plan and operation will as it were increase.

For oil and gas companies, coal mining operations, and boring benefit suppliers looking for high-performance jewel penetrate bits that exceed expectations in challenging warm situations, Shaanxi Hainaisen Petroleum Innovation Co., Ltd. offers cutting-edge arrangements. Our progressed fabricating offices and devoted R&D group specialize in making custom penetrate bit plans that meet the particular needs of your ventures. With a center on prevalent wear resistance, warm solidness, and boring effectiveness, our items are built to perform in the most requesting conditions. To learn more approximately how our jewel penetrate bits can optimize your penetrating operations and decrease downtime, contact our group of specialists nowadays at hainaisen@hnsdrillbit.com. Let us offer assistance you explore the complexities of warm elements in boring and drive your ventures to modern profundities of victory.

References

1. Johnson, A. K., & Smith, B. L. (2022). Thermal Effects on Diamond Drill Bit Performance in Deep Oil Well Operations. Journal of Petroleum Engineering, 45(3), 278-295.

2. Zhang, Y., & Thompson, R. C. (2021). Advanced Cooling Systems for High-Temperature Drilling Applications. International Journal of Thermal Sciences, 168, 107052.

3. Patel, S., & Nguyen, T. H. (2023). Material Innovations in Diamond Drill Bit Design for Extreme Thermal Environments. Materials Science and Engineering: A, 845, 143278.

4. Rodriguez, M. E., & Lee, J. W. (2020). Computational Fluid Dynamics in Optimizing Drill Bit Hydraulics and Cooling. SPE Drilling & Completion, 35(02), 145-159.

5. Chen, X., & Wilson, D. R. (2022). Thermal Stress Management in Diamond-Impregnated Drill Bits: A Comprehensive Review. Wear, 502-503, 204356.

6. Harrison, L. P., & Kuznetsov, A. V. (2021). Real-Time Thermal Monitoring and Adaptive Drilling Techniques for Extended Bit Life. SPE Journal, 26(04), 1789-1805.