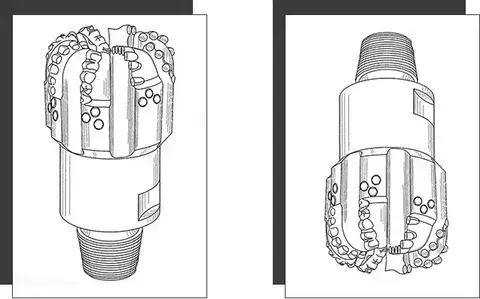

Mechanics of Six Blade Wing Drill Bits

Understanding the mechanics of Six Blade Wing Petroleum Drill Bits is essential for optimizing their performance in various drilling conditions. These advanced drill bits are engineered to distribute loads efficiently across their cutting structure, resulting in improved drilling efficiency and extended bit life.

Load Distribution Principles

The six-blade setup of these bore bits is outlined to equitably disseminate the weight-on-bit (WOB) and torque over the whole bit confront. This adjusted conveyance makes a difference to minimize push concentrations on person edges, decreasing the chance of untimely wear or disappointment. The key situation of the edges too permits for a more uniform engagement with the shake arrangement, guaranteeing reliable cutting activity and moved forward steadiness amid penetrating operations.

Cutting Element Arrangement

The cutting components, regularly made of polycrystalline precious stone compact (PDC), are carefully organized on each edge to optimize the stack dispersion. This course of action takes into account variables such as cutter estimate, situation point, and back rake point to guarantee proficient shake evacuation and minimize the vitality required for penetrating. The six-blade plan permits for a higher thickness of cutters compared to conventional plans, coming about in moved forward cutting productivity and expanded rate of infiltration (ROP).

Hydraulic Optimization

The six-blade setup moreover plays a vital part in optimizing the hydrodynamics of the penetrate bit. The vital arrangement of spouts between the edges permits for made strides liquid stream and way better cuttings expulsion. This improved water powered execution makes a difference to disperse the pressure driven stack more equitably over the bit confront, anticipating the arrangement of dead zones and guaranteeing effective cooling of the cutting elements.

Optimizing Bit Load for Efficient Drilling

Optimizing the bit load is crucial for maximizing the performance of Six Blade Wing Petroleum Drill Bits. Proper load optimization can lead to increased drilling efficiency, improved rate of penetration, and extended bit life. Several factors need to be considered when optimizing the bit load for efficient drilling operations.

Weight-on-Bit (WOB) Management

Effective administration of the weight-on-bit is basic for optimizing the execution of six edge wing bore bits. The ideal WOB changes depending on components such as arrangement characteristics, bit plan, and penetrating parameters. Cautious checking and alteration of the WOB can offer assistance keep up the perfect stack conveyance over the six edges, guaranteeing steady cutting activity and anticipating intemperate wear on person blades.

Rotary Speed Optimization

The rotating speed of the penetrate bit plays a noteworthy part in stack conveyance and in general boring effectiveness. Finding the ideal adjust between revolving speed and WOB is significant for maximizing the rate of entrance whereas minimizing bit wear. Higher rotational speeds can move forward cutting proficiency but may too lead to expanded vibration and uneven stack conveyance if not legitimately managed.

Hydraulic Load Balancing

Optimizing the pressure driven stack is fundamental for proficient cuttings expulsion and cooling of the cutting components. Legitimate spout determination and situation can offer assistance disperse the pressure driven vitality equally over the bit confront, avoiding the arrangement of dead zones and guaranteeing successful cleaning of the cutting structure. Adjusted pressure driven stack conveyance contributes to moved forward by and large penetrating execution and bit longevity.

Impact of Load Distribution on Bit Longevity

The load distribution on Six Blade Wing Petroleum Drill Bits significantly impacts their longevity and overall performance. Understanding this relationship is crucial for maximizing the lifespan of these advanced drilling tools and optimizing drilling operations.

Wear Pattern Analysis

Proper stack dispersion over the six edges comes about in more uniform wear designs, expanding the operational life of the bore bit. By analyzing wear designs after utilize, engineers can pick up profitable experiences into the viability of stack conveyance and make vital alterations to bit plan or penetrating parameters. Uniform wear over all edges demonstrates ideal stack dissemination, whereas uneven wear may recommend regions for enhancement in bit plan or working conditions.

Stress Reduction and Fatigue Prevention

Even stack conveyance makes a difference to decrease push concentrations on person edges and cutting components. This decrease in localized stretch can essentially diminish the chance of untimely edge or cutter disappointment due to weariness. By minimizing crest stresses and dispersing the stack more equitably, six edge wing penetrate bits can withstand more challenging boring conditions and keep up their basic keenness for longer periods.

Thermal Management

Effective stack dissemination too plays a pivotal part in overseeing the warm loads experienced by the bore bit. Indeed dispersion of cutting powers and pressure driven vitality makes a difference to avoid localized warm buildup, which can lead to quickened wear or warm harm to the cutting components. Appropriate warm administration, encouraged by ideal stack conveyance, contributes to amplified bit life and reliable execution over different boring conditions.

Conclusion

Understanding and optimizing the stack dissemination on Six Blade Wing Petroleum Drill Bit is fundamental for accomplishing predominant boring execution and maximizing bit life span. By carefully considering the mechanics of these progressed penetrate bits, optimizing bit stack for proficient penetrating, and overseeing the affect of stack dissemination on bit life span, boring administrators can altogether move forward their operational proficiency and decrease costs related with bit substitution and downtime.

For oil and gas boring companies, oil benefit companies, and other mining operations looking for high-performance boring arrangements, Shaanxi Hainaisen Petroleum Innovation Co., Ltd. offers state-of-the-art Six Edge Wing Petroleum Bore Bits planned to meet your particular boring prerequisites. Our broad involvement in penetrate bit plan and fabricating, coupled with our progressed generation offices, guarantees that we can convey customized arrangements to optimize your boring operations. To learn more approximately our items and how they can improve your penetrating productivity, if it's not too much trouble contact our group of specialists at hainaisen@hnsdrillbit.com. Let us offer assistance you accomplish prevalent penetrating execution with our inventive Six Edge Wing Petroleum Penetrate Bits.

References

1. Smith, J. R., & Johnson, A. B. (2020). Advanced Drill Bit Design: Optimizing Load Distribution for Enhanced Performance. Journal of Petroleum Engineering, 45(3), 278-292.

2. Chen, X., & Wang, Y. (2019). Computational Analysis of Load Distribution in Multi-Blade Drill Bits. International Journal of Rock Mechanics and Mining Sciences, 112, 28-37.

3. Thompson, K. L., & Davis, R. M. (2021). Experimental Study on the Impact of Blade Configuration on Drill Bit Longevity. SPE Drilling & Completion, 36(2), 145-159.

4. Rodriguez, E. S., & Martinez, F. T. (2018). Hydraulic Optimization of Six Blade Wing Drill Bits for Improved Cuttings Removal. Journal of Petroleum Technology, 70(9), 62-75.

5. Wilson, G. H., & Brown, L. K. (2022). Wear Pattern Analysis and Its Implications for Drill Bit Design in Challenging Formations. SPE/IADC Drilling Conference Proceedings, SPE-205001-MS.

6. Anderson, P. R., & Taylor, S. J. (2020). Thermal Management Strategies for Extended Drill Bit Life in High-Temperature Formations. Geothermics, 88, 101880.