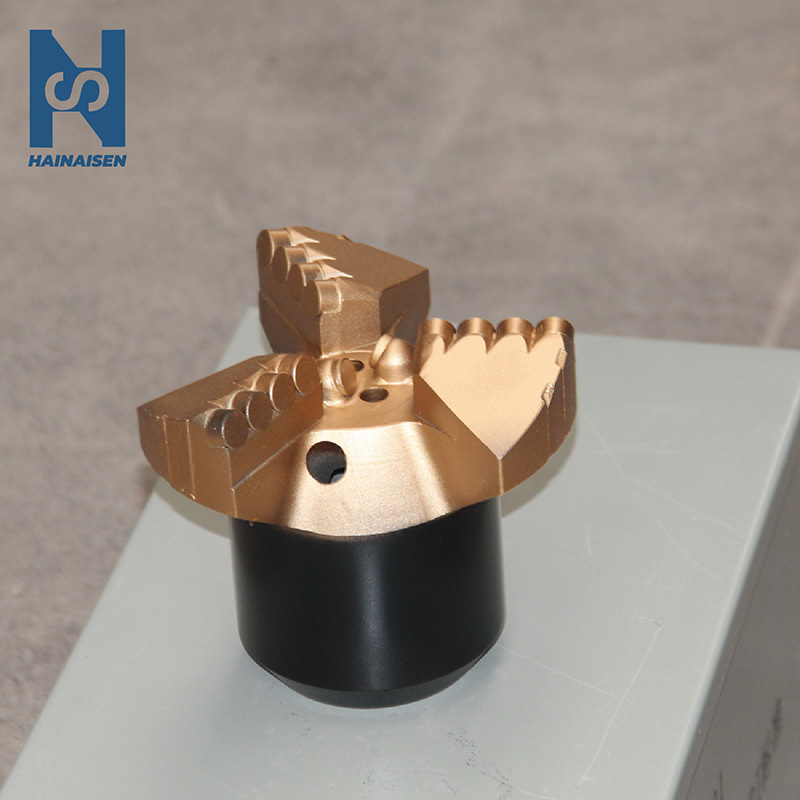

153mm PDC Concave Bit

Bit size: 153mm(50-150mm)

Number of Blade: 3

Number of Nozzle: 5

PDC cutter :1308

Connection type: 63.5cone buckle(customized)

Package Details: customized

Applicable strata:1-12

Minimum Order Quantity : 10 pieces

Price : To be negotiable

Delivery Time : 5-7 business days

Payment Terms : T/T, L/C

- Product Description

153mm PDC Concave Bit: Cutting-Edge Drilling Solutions by SHAANXI HAINAISEN

SHAANXI HAINAISEN INTELLIGENT EQUIPMENT MANUFACTURING CO.,LTD is a leading manufacturer and supplier of high-quality 153mm PDC Concave Bits. Our advanced manufacturing techniques and innovative design ensure superior performance in challenging drilling environments. With over a decade of industry experience, we've established ourselves as a trusted partner for oil & gas, mining, and water well drilling operations worldwide.

Why Choose Our 153mm PDC Concave Bit?

- Superior cutting efficiency for faster penetration rates

- Enhanced durability with wear-resistant materials

- Optimized hydraulics for improved cuttings removal

- Customizable design to meet specific formation needs

- Backed by rigorous quality control and testing

Applications:

Our 153mm PDC Concave Bits excel in various drilling applications:

- Oil & Gas Exploration:

- Deep well drilling in hard formations

- Horizontal and directional drilling

- Offshore drilling operations

- Mining Industry:

- Coal bed methane extraction

- Mineral exploration

- Hard rock drilling

- Water Well Drilling:

- Large diameter water wells

- Geothermal drilling projects

- Aquifer exploration

- Geotechnical Engineering:

- Foundation drilling for large structures

- Soil sampling and core recovery

Customization Service:

We understand that every drilling project is unique. Our team of experts works closely with clients to design and manufacture products tailored to specific geological formations and operational requirements. This customization ensures optimal performance and cost-effectiveness for your drilling projects.

Material:

Our bits feature premium-grade polycrystalline diamond compact (PDC) cutters mounted on a high-strength steel body. This combination delivers exceptional durability and cutting efficiency, even in the most challenging drilling conditions.

Quality Control:

Every product undergoes rigorous quality control measures:

- Advanced computer-aided design and simulation

- Precision manufacturing with state-of-the-art equipment

- Comprehensive testing for balance, runout, and structural integrity

- Field performance analysis and continuous improvement

Why Choose HAINAISEN:

- 10+ years of industry expertise

- ISO 9001:2015 certified manufacturing facility

- Continuous R&D for product innovation

- Responsive technical support and after-sales service

- Competitive pricing without compromising quality

Shipment & Samples:

We offer flexible shipping options to meet your project timelines. Sample bits are available for performance testing and evaluation. Contact us for more details on our sampling program.

Packaging and Transportation:

Our products are securely packaged in custom-designed crates to ensure safe transportation. We work with reliable logistics partners to deliver your order on time, anywhere in the world.

Transaction Feedback:

We value your input. After every transaction, we encourage customers to provide feedback on product performance and service quality. This helps us continually improve and maintain our high standards.

After-Sales Service:

Our commitment doesn't end with delivery. We offer comprehensive after-sales support, including:

- Technical consultation for optimal bit selection and operation

- Performance analysis and optimization recommendations

- Warranty support and rapid response to any issues

Qualification Certification:

SHAANXI HAINAISEN holds multiple industry certifications, including ISO 9001:2015 and API Spec Q1. These certifications demonstrate our commitment to quality and continuous improvement in manufacturing processes.

FAQ:

Q: What is the average lifespan of a product?

A: The lifespan varies depending on formation and operating conditions. Typically, our bits last 30-50% longer than standard PDC bits.

Q: Can you provide bit performance guarantees?

A: Yes, we offer performance guarantees based on specific project requirements and conditions.

Q: How long does it take to manufacture a custom product?

A: Custom orders usually take 4-6 weeks from design approval to shipment.

Q: Do you offer technical support for bit selection?

A: Absolutely. Our engineering team provides comprehensive support to help you choose the right bit for your project.

Q: What payment terms do you offer?

A: We offer various payment options, including L/C, T/T, and Western Union. Terms are negotiable for large orders.

Contact Us:

Ready to experience the superior performance of our 153mm PDC Concave Bits? Contact us today at hainaisen@hnsdrillbit.com for a quote or to discuss your specific drilling needs.

VIEW MOREThree Blade Concave Drill Bit Api For Manganese Coal Mines

VIEW MOREThree Blade Concave Drill Bit Api For Manganese Coal Mines VIEW MORE113mm 3 Blades Steel Body PDC Bit

VIEW MORE113mm 3 Blades Steel Body PDC Bit VIEW MORE3 Blades PDC Rock Bit

VIEW MORE3 Blades PDC Rock Bit VIEW MORE3 Blades PDC Mining Bits

VIEW MORE3 Blades PDC Mining Bits VIEW MOREDirectional Three Blade PDC Drill Bit

VIEW MOREDirectional Three Blade PDC Drill Bit VIEW MOREDrilling Tool Coal Mining Bit

VIEW MOREDrilling Tool Coal Mining Bit VIEW MORECoal Mine Drilling Drill Bit Directional Three Blade PDC Drill Bit

VIEW MORECoal Mine Drilling Drill Bit Directional Three Blade PDC Drill Bit VIEW MORECoal Mines Use Haineisen PDC Drill Bits

VIEW MORECoal Mines Use Haineisen PDC Drill Bits