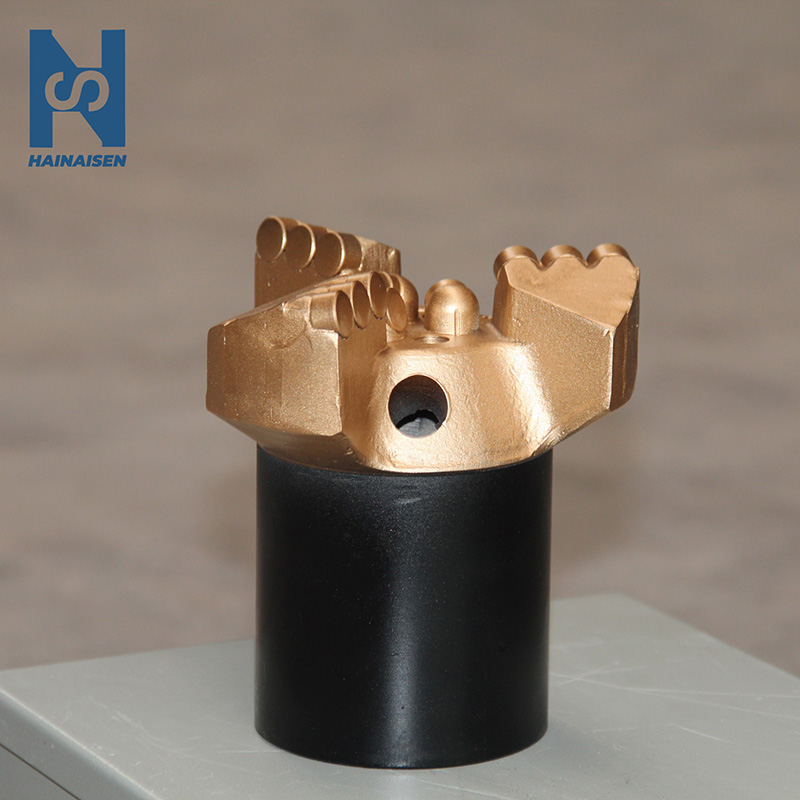

Steel Body PDC Drill Bit

Bit size: 113mm(50-150mm)

Number of Blade: 3

Number of Nozzle: 5

PDC cutter :1308

Connection type: 63.5cone buckle(customized)

Package Details: customized

Applicable strata:1-12

Minimum Order Quantity : 10 pieces

Price : To be negotiable

Delivery Time : 5-7 business days

Payment Terms : T/T, L/C

- Product Description

Steel Body PDC Drill Bit - High-Performance Drilling Solution

SHAANXI HAINAISEN INTELLIGENT EQUIPMENT MANUFACTURING CO.,LTD is a leading manufacturer and supplier of Steel Body PDC Drill Bits. With our cutting-edge technology and decades of industry expertise, we offer superior drilling solutions for oil, gas, and mining applications. Our products are designed for optimal performance, durability, and cost-effectiveness.

Why Choose Our Steel Body PDC Drill Bit?

- Advanced PDC cutter technology for superior drilling efficiency

- Durable steel body construction for extended bit life

- Optimized hydraulics for improved hole cleaning and cooling

- Customizable designs to meet specific drilling requirements

- Proven performance in various formation types

Applications:

Our Steel Body PDC Drill Bits are versatile tools suitable for a wide range of drilling applications:

- Oil and Gas Exploration:

- Offshore and onshore drilling operations

- Vertical, directional, and horizontal well drilling

- Shale and unconventional resource extraction

- Mining and Mineral Exploration:

- Coal bed methane (CBM) drilling

- Hard rock mining

- Mineral exploration and core sampling

- Geothermal Energy:

- Geothermal well drilling

- Heat extraction system installation

- Water Well Drilling:

- Municipal water supply projects

- Agricultural irrigation wells

- Industrial water well construction

- Construction and Infrastructure:

- Foundation drilling for large structures

- Tunnel boring and excavation

- Soil stabilization projects

Customization Service:

At HAINAISEN, we understand that every drilling project is unique. Our team of experienced engineers works closely with clients to design and manufacture custom products tailored to specific formation characteristics and drilling parameters. This ensures optimal performance and cost-effectiveness for your projects.

Material:

Our products are crafted using high-grade steel alloys and premium polycrystalline diamond compact (PDC) cutters. This combination ensures exceptional durability, wear resistance, and cutting efficiency in various drilling conditions.

Quality Control:

HAINAISEN upholds stringent quality control protocols at every stage of the manufacturing process, from sourcing premium raw materials to the final assembly. Each product undergoes rigorous testing and comprehensive inspections, including performance evaluations and compliance checks, to ensure they not only meet our exceptionally high internal standards but also adhere to all relevant industry regulations, delivering consistent reliability and superior quality.

Why Choose HAINAISEN:

- 10+ years of industry experience

- State-of-the-art manufacturing facilities

- Dedicated R&D team for continuous innovation

- Comprehensive technical support and after-sales service

- Competitive pricing and flexible solutions

Shipment Samples:

We offer sample products for evaluation upon request. Contact our sales team to discuss your specific requirements and arrange for sample shipment.

Packaging and Transportation:

Our products are carefully packaged in sturdy wooden crates or metal containers to ensure safe transportation. We work with reliable logistics partners to deliver your orders efficiently and securely.

Transaction Feedback:

We value customer feedback and continuously strive to improve our products and services. Share your experience with us to help us serve you better.

After-Sales Service:

HAINAISEN provides comprehensive after-sales support, including:

- Technical consultation

- On-site troubleshooting

- Repair and maintenance services

- Performance optimization recommendations

Qualification Certification:

HAINAISEN is ISO 9001:2015 certified, ensuring our commitment to quality management and customer satisfaction.

FAQ:

Q1: What is the typical lifespan of a product?

A1: The lifespan varies depending on formation characteristics and drilling parameters. On average, our bits can drill 3000-5000 meters in moderate formations.

Q2: Can you provide custom bit designs for specific formations?

A2: Yes, we offer customized product designs tailored to your unique drilling requirements.

Q3: What is the lead time for custom orders?

A3: Lead times for custom orders typically range from 4-6 weeks, depending on complexity and quantity.

Q4: Do you offer technical support for bit selection and optimization?

A4: Yes, our experienced technical team provides comprehensive support for bit selection, optimization, and troubleshooting.

Q5: Are your Steel Body PDC Drill Bits suitable for high-temperature applications?

A5: Yes, we offer specially designed bits for high-temperature environments, capable of withstanding temperatures up to 350°C (662°F).

Contact Us:

For inquiries or to place an order, please email us at hainaisen@hnsdrillbit.com.

VIEW MORE153mm PDC Concave Bit

VIEW MORE153mm PDC Concave Bit VIEW MOREThree Blade Concave Drill Bit Api For Manganese Coal Mines

VIEW MOREThree Blade Concave Drill Bit Api For Manganese Coal Mines VIEW MORE113mm 3 Blades Steel Body PDC Bit

VIEW MORE113mm 3 Blades Steel Body PDC Bit VIEW MOREThree Blades Steel Body PDC Bit

VIEW MOREThree Blades Steel Body PDC Bit VIEW MORE3 Blades Steel Body PDC Bit

VIEW MORE3 Blades Steel Body PDC Bit VIEW MOREDrilling Tool Coal Mining Bit

VIEW MOREDrilling Tool Coal Mining Bit VIEW MORECoal Mine Drilling Drill Bit Directional Three Blade PDC Drill Bit

VIEW MORECoal Mine Drilling Drill Bit Directional Three Blade PDC Drill Bit VIEW MOREPolycrystalline Diamond Compact Drill Bits

VIEW MOREPolycrystalline Diamond Compact Drill Bits