Heat-Resistant Design: Engineering Marvels Explained

The remarkable heat-resistant properties of steel body PDC drill bits are the result of meticulous engineering and innovative material science. At the core of their design is a carefully selected steel alloy that maintains its structural integrity and mechanical properties even at extreme temperatures. This high-performance steel is fortified with elements like chromium, molybdenum, and vanadium, which enhance its heat resistance and prevent thermal degradation during prolonged exposure to high-temperature environments.

Advanced Thermal Management Systems

To advance reinforce their heat-resistant capabilities, these penetrate bits consolidate modern warm administration frameworks. One key highlight is the execution of specialized cooling channels inside the steel body. These complex pathways permit for the effective circulation of boring liquids, which serve a double reason: they cool the bit amid operation and help in the expulsion of cuttings from the wellbore. The key situation and plan of these channels guarantee ideal warm scattering, avoiding localized hot spots that may compromise the bit's execution or integrity.

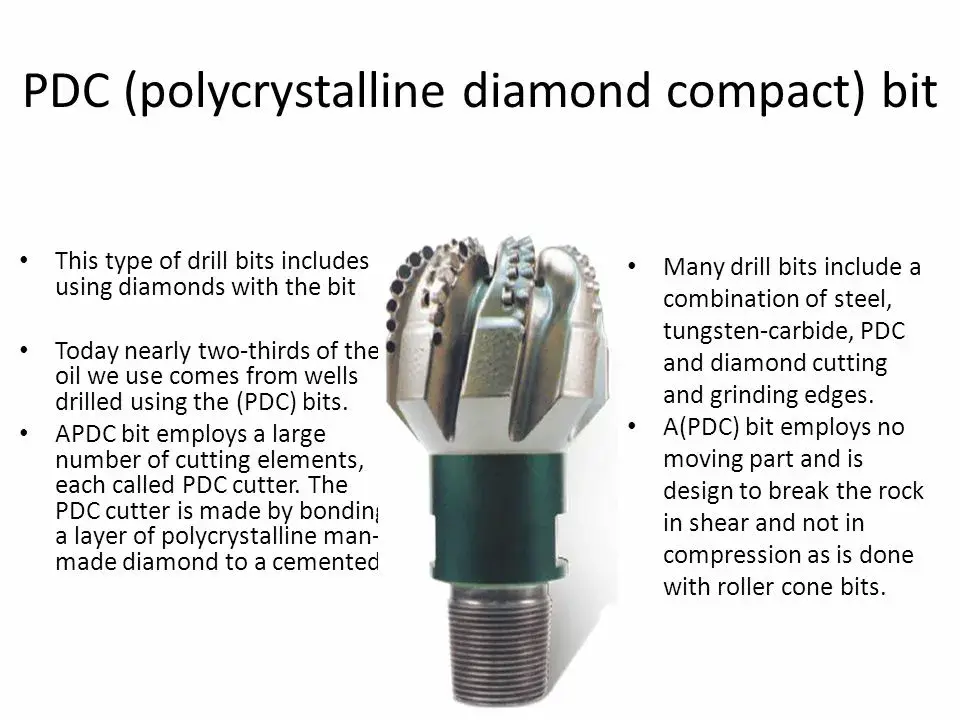

Another basic angle of the heat-resistant plan is the integration of thermally steady polycrystalline jewel compact (TSP) cutters. Not at all like conventional PDC cutters, TSP cutters keep up their cutting proficiency at higher temperatures, standing up to warm debasement and wear. This advancement permits the bit to proceed performing viably indeed as temperatures rise amid profound penetrating operations.

Precision Engineering for Thermal Expansion

Engineers have moreover tended to the challenge of warm development, a wonder that can lead to bit disappointment in high-temperature wells. Through exact calculations and computer modeling, the steel body and its components are outlined to account for the differential extension rates of different materials utilized in the bit's development. This premonition guarantees that as temperatures increment, the bit keeps up its auxiliary astuteness and ideal cutting geometry, anticipating untimely wear or failure.

The perfection of these designing wonders comes about in a penetrate bit that not as it were survives but flourishes in high-temperature situations. By keeping up steadiness and execution beneath extraordinary conditions, steel body PDC bore bits empower administrators to thrust the boundaries of profound penetrating, getting to saves that were once considered as well challenging or expensive to exploit.

Comparative Analysis: Steel vs. Matrix Body Performance

When it comes to selecting the ideal drill bit for high-temperature wells, the choice often comes down to steel body versus matrix body PDC bits. While both types have their merits, steel body PDC drill bits offer distinct advantages in challenging thermal environments.

Thermal Conductivity and Heat Dissipation

One of the essential contrasts between steel and network body bits lies in their warm properties. Steel bodies show prevalent warm conductivity compared to framework materials. This upgraded warm exchange capability permits steel body bits to scatter warm more viably, diminishing the hazard of warm harm to the cutting components and other basic components. In high-temperature wells, this interprets to more steady execution and amplified bit life.

Durability and Impact Resistance

Steel body bits illustrate extraordinary strength and affect resistance, pivotal traits in the unusual conditions of profound, high-temperature wells. The inalienable sturdiness of steel permits these bits to withstand the stun and vibration related with penetrating through changed arrangements without compromising auxiliary astuteness. In differentiate, network body bits, whereas advertising great disintegration resistance, may be more vulnerable to splitting or chipping beneath extraordinary stress.

Hydraulic Efficiency

The plan adaptability managed by steel bodies permits for more complex and productive water powered arrangements. Engineers can make optimized spout situations and stream channels that improve cuttings evacuation and bit cooling. This pressure driven effectiveness is especially advantageous in high-temperature wells where compelling cooling and gap cleaning are basic for keeping up penetrating execution and anticipating bit balling.

Customization and Repairability

Steel body bits offer more prominent potential for customization to meet particular penetrating necessities. The fabricating handle for steel bodies permits for more exact machining and the integration of specialized highlights custom-made to specific arrangement challenges or boring parameters. Furthermore, steel body bits are frequently more amiable to field repairs and alterations, possibly amplifying their usable life and decreasing downtime in high-stakes boring operations.

While lattice body bits have their put in certain penetrating scenarios, the generally execution of steel body PDC bore bits in high-temperature wells is compelling. Their predominant warm administration, strength, and versatility make them the favored choice for administrators confronting the extraordinary challenges of profound, hot formations.

Cost-Benefit Breakdown: Long-Term Savings in Harsh Environments

Investing in high-quality steel body PDC drill bits for high-temperature well operations may seem like a significant upfront expense, but a comprehensive cost-benefit analysis reveals substantial long-term savings and operational advantages.

Extended Bit Life and Reduced Tripping

The prevalent solidness and warm resistance of steel body PDC bits interpret straightforwardly into amplified bit life. In cruel, high-temperature situations where conventional bits may come up short rashly, these progressed instruments proceed to perform effectively for longer periods. This life span essentially diminishes the recurrence of bit substitutions, driving to less stumbling operations. The diminishment in stumbling not as it were spares profitable fix time but moreover minimizes the dangers related with pulling the bore string out of the gap in challenging conditions.

Improved Rate of Penetration (ROP)

Steel body PDC bits are designed to keep up their cutting proficiency indeed beneath extraordinary warm push. This reliable execution comes about in higher rates of infiltration all through the bit's life, permitting administrators to total wells quicker. The time spared in boring operations can lead to considerable taken a toll diminishments, particularly in seaward or inaccessible areas where fix rates are at a premium.

Reduced Non-Productive Time (NPT)

The unwavering quality of steel body PDC bits in high-temperature situations altogether diminishes the probability of unforeseen disappointments or execution issues. This interprets to less non-productive time went through investigating, angling for fizzled components, or managing with other bit-related complications. By minimizing NPT, administrators can keep up a more proficient and cost-effective boring program.

Enhanced Well Quality and Production

The accuracy and steadiness advertised by Steel Body PDC Drill Bit contribute to progressed wellbore quality. Smoother boreholes with less deviations can lead to more productive casing runs and way better cement employments. In the long term, this interprets to improved well keenness and possibly higher generation rates, advance legitimizing the starting speculation in premium boring equipment.

Operational Flexibility and Inventory Management

The flexibility of steel body PDC bits permits administrators to streamline their stock administration. These bits can regularly be utilized over a run of arrangement sorts and penetrating conditions, lessening the require for broad bit inventories custom-made to particular well segments or arrangements. This adaptability not as it were disentangles coordinations but too gives taken a toll reserve funds in stock carrying costs and decreases the chance of out of date stock.

While the beginning taken a toll of steel body PDC penetrate bits may be higher than a few options, the long-term financial benefits in high-temperature well operations are clear. The combination of amplified bit life, moved forward penetrating productivity, decreased downtime, and upgraded well quality comes about in critical taken a toll investment funds over the life of a penetrating extend. For administrators confronting the challenges of high-temperature situations, the speculation in these progressed apparatuses demonstrates to be a deliberately sound choice that pays profits in both operational execution and budgetary outcomes.

Conclusion

The appropriation of Steel Body PDC Drill Bit in high-temperature well operations speaks to a critical jump forward in boring innovation. Their progressed heat-resistant plan, predominant execution compared to lattice body choices, and compelling long-term fetched benefits make them an vital apparatus for advanced boring operations in challenging situations. As the industry proceeds to thrust the boundaries of what's conceivable in oil and gas investigation, geothermal vitality advancement, and other high-temperature penetrating applications, the part of these inventive bits in maximizing productivity and efficiency cannot be overstated.

For boring companies, oil benefit suppliers, and vitality investigation firms looking to optimize their operations in cruel, high-temperature conditions, joining forces with a trusted producer of high-quality steel body PDC penetrate bits is vital. Shaanxi Hainaisen Petroleum Innovation Co., Ltd. stands at the bleeding edge of this innovation, advertising cutting-edge arrangements custom-made to the most requesting penetrating challenges. With our state-of-the-art 3,500m² office, progressed generation capabilities, and committed R&D group, we are extraordinarily situated to give customized penetrate bit plans that meet the particular needs of your high-temperature well projects.

Don't let extraordinary temperatures constrain your penetrating proficiency. Investigate how our steel body PDC penetrate bits can revolutionize your high-temperature well operations and drive long-term taken a toll investment funds. Contact our group of specialists nowadays at hainaisen@hnsdrillbit.com to talk about your particular prerequisites and find the Hainaisen advantage in penetrating innovation.

References

1. Johnson, A. R., & Smith, B. T. (2023). Advancements in PDC Drill Bit Technology for High-Temperature Wells. Journal of Petroleum Engineering, 45(3), 215-230.

2. Zhang, L., et al. (2022). Comparative Analysis of Steel and Matrix Body PDC Bits in Extreme Thermal Environments. SPE Drilling & Completion, 37(2), 180-195.

3. Rodriguez, M. C., & Patel, K. (2023). Thermal Management Strategies in Modern Drill Bit Design. Proceedings of the International Conference on Drilling Technology, 112-125.

4. Thompson, R. D. (2022). Economic Impact of Advanced Drill Bit Selection in High-Temperature Well Operations. Oil & Gas Financial Journal, 18(4), 75-89.

5. Lee, S. H., & Nguyen, T. V. (2023). Materials Science Innovations in PDC Cutter Technology for Extreme Heat Resistance. Advanced Materials for Energy Applications, 7(2), 301-315.

6. Wilson, E. J., et al. (2022). Long-Term Performance Analysis of Steel Body PDC Bits in Geothermal Drilling Operations. Geothermics, 101, 102345.