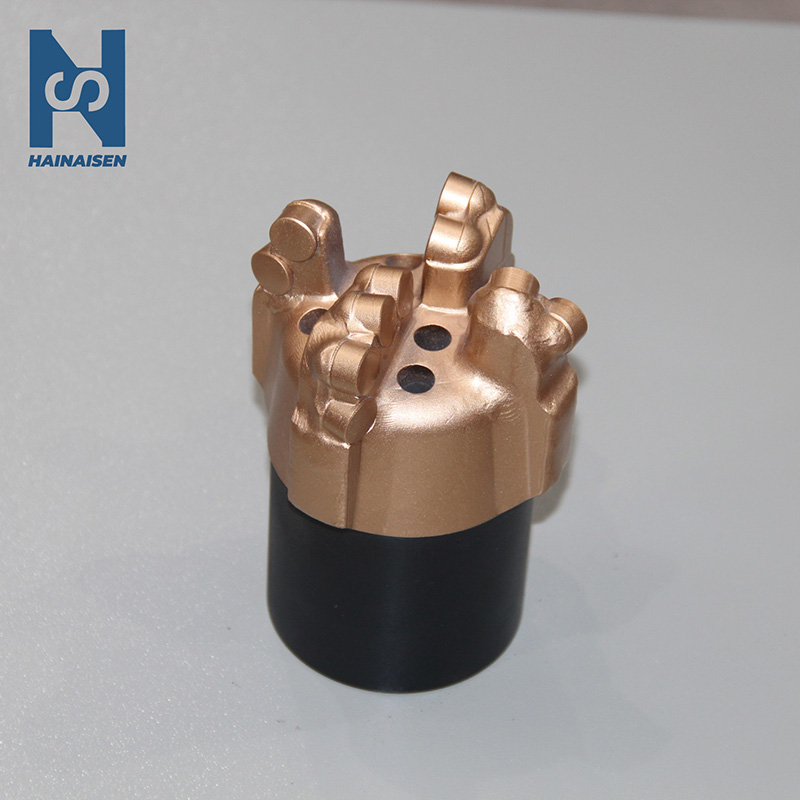

94mm Four Wing Arc Angle Drill Bit

Bit size: 94mm(60-165mm)

Number of Blade: 4

Number of Nozzle: 4

PDC cutter :1308

Connection type: 63.5cone buckle(customized)

Package Details: customized

Applicable strata:1-12

Minimum Order Quantity : 10 pieces

Price : To be negotiable

Delivery Time : 5-7 business days

Payment Terms : T/T, L/C

- Product Description

SHAANXI HAINAISEN Your Trusted 94mm Four Wing Arc Angle Drill Bit Manufacturer

As a leading manufacturer and supplier, SHAANXI HAINAISEN offers superior 94mm Four Wing Arc Angle Drill Bits. Our advanced technology, rigorous quality control, and decades of industry expertise ensure top-notch performance. These drill bits excel in durability, impact resistance, and thermal stability, making them ideal for oil, gas, and mining operations. Choose HAINAISEN for unmatched reliability and efficiency in your drilling projects.

Why Choose Our 94mm Four Wing Arc Angle Drill Bit?

- Enhanced durability with wear-resistant materials

- Optimized cutting structure for improved drilling efficiency

- Superior thermal stability for extended lifespan

- Customizable design to meet specific project requirements

- Backed by comprehensive technical support and after-sales service

Applications:

Our 94mm Four Wing Arc Angle Drill Bit is versatile and widely used across various industries:

- Oil and Gas Exploration:

- Offshore and onshore drilling operations

- Directional and horizontal drilling

- Hard formation penetration

- Mining Industry:

- Coal mining and exploration

- Mineral extraction projects

- Geothermal drilling operations

- Water Well Drilling:

- Deep water well construction

- Groundwater exploration

- Irrigation system development

- Construction and Infrastructure:

- Foundation drilling for large structures

- Tunnel boring operations

- Bridge pier construction

- Geotechnical Engineering:

- Soil sampling and core drilling

- Environmental site investigations

- Geothermal energy projects

Customization Service:

We understand that every drilling project has unique requirements. Our team of experts works closely with clients to tailor the product to specific needs. We offer customization in:

- Cutting structure design

- Material composition

- Special coatings for enhanced performance

- Gauge protection features

- Hydraulic optimization

Material:

Our products are crafted using premium-grade materials, including:

- High-strength steel body

- Polycrystalline Diamond Compact (PDC) cutters

- Tungsten carbide matrix

Quality Control:

We maintain strict quality standards throughout the manufacturing process:

- ISO 9001:2015 certified quality management system

- Rigorous testing at each production stage

- Final inspection using advanced measurement tools

Why Choose HAINAISEN:

10+ years of industry experience: With more than a decade immersed in the industry, we've accumulated deep insights, overcome numerous challenges, and built a solid foundation of expertise.

State-of-the-art manufacturing facility: Our advanced manufacturing facility is outfitted with the latest equipment and technology, enabling us to produce high-quality products with precision and efficiency.

Dedicated R&D team for continuous innovation: Staffed by passionate experts, our R&D team constantly explores new ideas and technologies, driving innovation to keep our offerings at the forefront.

Competitive pricing without compromising quality: We carefully optimize our processes to offer prices that stand out in the market, all while upholding strict quality standards.

Excellent customer support and technical assistance: Our friendly and knowledgeable support team is always ready to help, providing prompt solutions and guidance to ensure your satisfaction.

Shipment and Samples:

- Fast and secure worldwide shipping

- Sample availability for performance testing

- Flexible order quantities to suit your needs

Packaging and Transportation:

- Robust packaging to ensure safe delivery

- Multiple shipping options available

- Real-time tracking for peace of mind

Transaction Feedback:

We value customer satisfaction and continuously improve based on feedback. Our clients appreciate our:

- Responsive communication

- On-time delivery

- Product performance reliability

After-Sales Service:

- Comprehensive warranty coverage

- Technical support for optimal bit performance

- Maintenance and repair services available

Qualification Certification:

- ISO 9001:2015 certified

- API Spec Q1 compliant

- CE marked for European market

FAQ:

Q1: What is the lifespan of a 94mm Four Wing Arc Angle Drill Bit?

A1: The lifespan varies depending on operating conditions, but our bits typically outperform industry standards.

Q2: Can these bits be used in high-temperature environments?

A2: Yes, our bits are designed to withstand high temperatures common in deep drilling operations.

Q3: Do you offer training for proper bit usage?

A3: We provide comprehensive training and documentation to ensure optimal bit performance.

Q4: What is the average delivery time for custom orders?

A4: Custom orders usually take 2-4 weeks, depending on specifications and quantity.

Q5: Are your drill bits environmentally friendly?

A5: Yes, our bits are designed for efficiency, reducing energy consumption and environmental impact.

Contact Us:

For inquiries or to place an order, please email us at hainaisen@hnsdrillbit.com.