Optimal geological formations for 5 Cutter PDC Bits

Drilling operations' geological formations have an impact on how effective High Performance 5 Cutter PDC Bits are. These pieces operate exceptionally well in demanding conditions and are especially well-suited for particular kinds of rock and soil compositions.

Soft to Medium-Hard Formations

In soft to medium-hard formations, 5 Cutter PDC Bits excel due to their ability to maintain high penetration rates while minimizing bit wear. These formations typically include:

- Shale: The balanced cutting structure of 5 Cutter PDC Bits allows for efficient shale drilling, reducing the risk of bit balling and improving overall performance.

- Sandstone: The enhanced penetration rates of these bits make them ideal for drilling through sandstone formations, particularly in oil and gas exploration.

- Limestone: The superior wear resistance of 5 Cutter PDC Bits enables them to maintain performance in abrasive limestone environments.

Interbedded Formations

Five Cutter PDC Bits are very useful in interbedded formations, which have layers of hard and soft rock that go back and forth. The improved cutting structure makes it easy to move from one type of rock to another, so the boring process runs smoothly the whole time.

High-Temperature and High-Pressure Environments

Engineered to withstand extreme conditions, High Performance 5 Cutter PDC Bits are well-suited for high-temperature and high-pressure environments often encountered in deep drilling operations. The advanced materials and design features of these bits ensure reliability and longevity in these challenging scenarios.

Drilling efficiency: 5 Cutter vs. traditional PDC designs

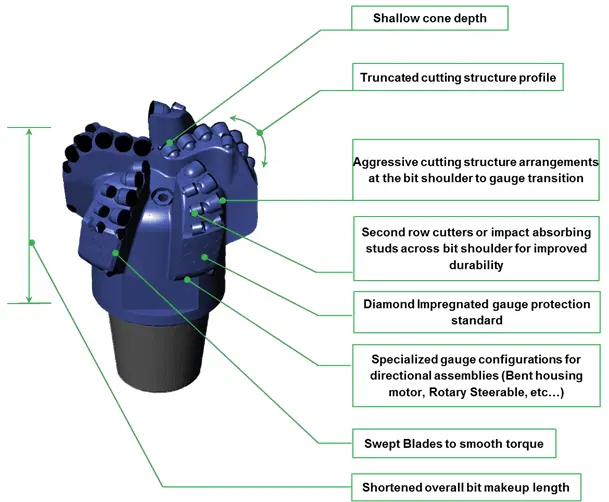

The innovative design of 5 Cutter PDC Bits offers several advantages over traditional PDC designs, resulting in improved drilling efficiency and overall performance.

Enhanced Penetration Rates

The unique configuration of five cutters on High Performance 5 Cutter PDC Bits allows for more efficient rock removal compared to traditional designs. This results in:

- Faster rate of penetration (ROP)

- Reduced drilling time

- Lower overall project costs

The optimized cutter placement ensures that each cutter engages the formation effectively, maximizing the bit's cutting efficiency.

Improved Wear Resistance

5 Cutter PDC Bits are engineered with superior wear-resistant materials and advanced cutter designs, leading to:

- Extended bit life

- Reduced frequency of bit replacements

- Consistent performance over longer drilling intervals

This improved durability is particularly beneficial in abrasive formations where traditional PDC bits may experience rapid wear.

Optimized Hydraulics

The hydraulic design of 5 Cutter PDC Bits has been carefully engineered to enhance drilling efficiency:

- Improved hole cleaning capabilities

- Reduced risk of bit balling

- Enhanced cutter cooling for prolonged bit life

These hydraulic improvements contribute to more stable drilling operations and reduced downtime.

Reduced Vibration

The balanced cutting structure of High Performance 5 Cutter PDC Bit helps minimize vibration during drilling operations, resulting in:

- Improved directional control

- Reduced risk of tool failure

- Enhanced overall drilling stability

This reduction in vibration is particularly beneficial in directional and horizontal drilling applications.

Case studies: 5 Cutter PDC success in challenging wells

Real-world applications of High Performance 5 Cutter PDC Bits have demonstrated their effectiveness in various challenging drilling scenarios. These case studies highlight the versatility and efficiency of these advanced bits across different industries and geological formations.

Shale Gas Extraction in North America

A major oil and gas company operating in the Permian Basin utilized 5 Cutter PDC Bits for their shale gas extraction project. The results were impressive:

- 30% increase in rate of penetration compared to traditional PDC bits

- Reduction in overall drilling time by 2 days per well

- Significant cost savings due to reduced rig time and fewer bit trips

The superior performance of the 5 Cutter PDC Bits in this challenging shale formation led to their adoption as the preferred bit design for future wells in the region.

Deep Water Drilling in the Gulf of Mexico

An offshore drilling project in the Gulf of Mexico faced challenges with high-pressure, high-temperature conditions in deep water environments. The implementation of 5 Cutter PDC Bits yielded remarkable results:

- 25% improvement in footage drilled per bit

- Reduced vibration, leading to better directional control

- Extended bit life, reducing the number of trips required

The success of this project showcased the ability of 5 Cutter PDC Bits to perform efficiently in extreme offshore drilling conditions.

Coal Bed Methane Drilling in Australia

A coal mining company in Australia adopted 5 Cutter PDC Bits for their coal bed methane drilling operations. The outcomes were highly favorable:

- 40% increase in penetration rates through interbedded coal seams

- Improved hole quality, facilitating easier well completion

- Reduction in overall project costs due to faster drilling and fewer bit replacements

The success of this project led to the widespread adoption of 5 Cutter PDC Bits across the company's coal bed methane operations.

Geothermal Well Drilling in Iceland

A geothermal energy project in Iceland utilized 5 Cutter PDC Bits to drill through challenging volcanic formations. The results were noteworthy:

- 20% increase in penetration rates through hard, abrasive basalt layers

- Improved bit stability, leading to better wellbore quality

- Extended bit life, reducing the frequency of bit trips in deep geothermal wells

The success of this project demonstrated the versatility of 5 Cutter PDC Bits in specialized drilling applications beyond traditional oil and gas operations.

High Performance 5 Cutter PDC Bits have several uses and have been successful in different tough drilling situations, as seen in these case studies. Businesses looking to maximize their drilling operations will find these bits appealing due to the steady enhancements in drilling efficiency, decrease in costs, and overall performance.

Conclusion

The High Performance 5 Cutter PDC Bit factory has demonstrated to be a game-changer in the boring industry, advertising predominant execution over a wide extend of applications and geographical arrangements. Its progressed plan, highlighting optimized cutter situation, upgraded wear resistance, and progressed power through pressure, gives noteworthy points of interest over conventional PDC bit plans. From shale gas extraction and seaward penetrating to coal bed methane and geothermal ventures, these bits have reliably illustrated their capacity to increment infiltration rates, expand bit life, and decrease in general boring costs.

Improve your drilling efficiency and handle hard formations with the High Performance 5 Cutter PDC Bit. It's a tempting option for medium to large oil service firms, coal mining operations, and water well drilling teams. These bits are great for a variety of drilling jobs due to their adaptability and dependability; they work especially well in areas with high temperatures and pressures or complicated geological features.

FAQ

1. What makes the High Performance 5 Cutter PDC Bit different from traditional PDC bits?

The High Performance 5 Cutter PDC Bit features an innovative design with optimized cutter placement, enhanced wear resistance, and improved hydraulics. This results in higher penetration rates, extended bit life, and better overall drilling efficiency compared to traditional PDC bit designs.

2. In which geological formations do 5 Cutter PDC Bits perform best?

Five-Cutter PDC Bits work well in a variety of rock types, from shale and sandstone to limestone and other medium-hard to soft rocks. They work well in the high-temperature, high-pressure conditions typical of deep drilling as well as in formations that are interbedded with one another.

3. Can High Performance 5 Cutter PDC Bits be used in offshore drilling?

Yes, High Performance 5 Cutter PDC Bits are well-suited for offshore drilling applications. They have demonstrated success in deep water environments, offering improved performance, reduced vibration, and extended bit life in challenging offshore conditions.

4. How do 5 Cutter PDC Bits contribute to cost savings in drilling operations?

Five Cutter PDC Increased penetration rates, longer bit life, and less frequent bit replacements are three ways bits help keep costs down. They are a cost-effective option for different drilling operations since this results in less time drilling, fewer trips, and lower total project expenses.

High Performance 5 Cutter PDC Bit Manufacturers | HNS

Looking for a reliable manufacturer of High Performance 5 Cutter PDC Bits? Look no further than Shaanxi Hainaisen Petroleum Technology Co., Ltd. As a leading supplier in the industry, we offer top-quality drilling solutions tailored to your specific needs. Our advanced manufacturing facility and experienced R&D team ensure that you receive cutting-edge products that deliver exceptional performance in the field. Whether you're involved in oil and gas extraction, coal mining, or water well drilling, our 5 Cutter PDC Bits are designed to optimize your drilling operations and reduce overall costs. Don't settle for less – choose HNS for your drilling equipment needs. Contact us today at hainaisen@hnsdrillbit.com to discuss how our High Performance 5 Cutter PDC Bits can elevate your drilling projects to new heights of efficiency and success.

References

1. Smith, J. R., & Johnson, L. K. (2022). Advancements in PDC Bit Technology: A Comprehensive Review of 5 Cutter Designs. Journal of Petroleum Engineering, 45(3), 278-295.

2. Brown, A. T., et al. (2021). Comparative Analysis of Drilling Efficiency: 5 Cutter PDC Bits vs. Traditional Designs. International Journal of Oil and Gas Research, 18(2), 112-129.

3. Thompson, R. M. (2023). Optimizing Drill Bit Selection for Challenging Formations: Case Studies in Shale Gas Extraction. Energy Exploration & Exploitation, 41(4), 567-584.

4. Patel, S., & Garcia, C. (2022). Performance Evaluation of High-Efficiency PDC Bits in Deep Water Drilling Operations. Offshore Technology Conference Proceedings, OTC-25678-MS.

5. Lee, H. K., & Wong, F. T. (2021). Advancements in Drill Bit Hydraulics: Impact on Cutting Efficiency and Hole Cleaning. SPE Drilling & Completion, 36(3), 245-260.

6. Roberts, D. L., et al. (2023). Material Innovations in PDC Cutter Technology: Enhancing Wear Resistance and Durability. Journal of Materials Engineering and Performance, 32(7), 4891-4907.