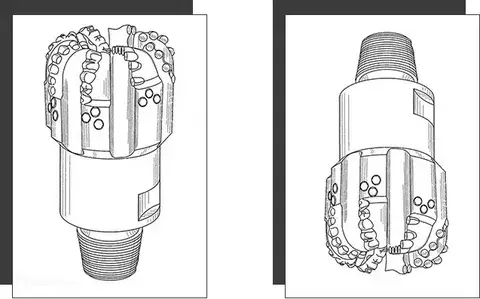

Key Differences in Bit Structure and Performance

Diamond PDC Drill Bit Structure

The Diamond PDC drill bit is different from other bits because it is made with a special structure. It is made up of polycrystalline diamond compact blades that are placed on a steel body, also called a matrix. The placement of these tools is planned to get the best cutting action and fluid flow, which improves the drilling performance.

One of the best things about PDC bits is that they can keep their cutting edge sharp while they are digging. This is done by constantly exposing new diamond material as the cutter gets worn down. The result is steady and effective drilling, even in rocks that are hard to work with.

Impregnated Bit Structure

Impregnated bits, on the other hand, have a core body that is filled with diamond particles. As the bit goes down during drilling, new diamond pieces are constantly showing up to keep the cutting action going. This form lets the wear happen slowly and steadily, which can be helpful in some drilling situations.

Performance Comparison

In terms of rate of penetration (ROP) and general drilling speed, Diamond PDC drill bits often do a better job than impregnated bits. PDC cutters can drill faster in a wide range of rocks because they cut more aggressively. Also, PDC bits usually need less weight on bit (WOB) to work at their best, which makes drilling tools less stressed.

Impregnated bits, while generally slower in terms of ROP, excel in extremely hard and abrasive formations where PDC cutters might struggle. Their gradual wear characteristics can provide more consistent performance over extended periods in these challenging conditions.

Cost-Efficiency Analysis: PDC vs Impregnated Bits

Initial Investment

When considering the cost-efficiency of drill bits, it's essential to look beyond the initial purchase price. Diamond PDC drill bits typically have a higher upfront cost compared to impregnated bits. This is due to the advanced manufacturing processes and materials used in their production, including high-quality steel bodies and premium-grade PDC cutters.

Impregnated bits, while generally less expensive initially, may require more frequent replacements depending on the drilling conditions. This factor should be carefully weighed against the potential long-term benefits of each bit type.

Operational Costs

The true cost-efficiency of a drill bit becomes apparent when considering operational costs over the life of the drilling project for a Diamond PDC Drill Bit manufacturer. Diamond PDC drill bits often demonstrate superior cost-efficiency in this regard, particularly in medium to soft formations. Their higher ROP and longer bit life can significantly reduce drilling time and the number of trips required for bit changes.

Impregnated bits may prove more cost-effective in extremely hard and abrasive formations where PDC bits might wear out quickly. In these scenarios, the slower but more consistent performance of impregnated bits can result in lower overall drilling costs.

Long-Term Value

When assessing long-term value, it's crucial to consider factors such as reduced downtime, improved drilling efficiency, and the potential for extended bit life. Diamond PDC drill bits often provide excellent long-term value due to their durability and consistent performance across a wide range of formations. Their ability to maintain a sharp cutting edge throughout the drilling process contributes to sustained efficiency and reduced overall project costs.

Impregnated bits, while potentially offering longer life in specific hard-rock applications, may not provide the same level of versatility and overall cost-efficiency as PDC bits in many drilling scenarios.

Optimal Drilling Conditions for Each Bit Type

Ideal Conditions for Diamond PDC Drill Bits

Diamond PDC drill bits excel in a wide range of drilling conditions, making them a versatile choice for many applications. They are particularly well-suited for:

- Medium to hard formations

- Directional and horizontal drilling operations

- High-temperature environments

- Formations with interbedded soft and hard layers

The advanced PDC cutter technology allows these bits to maintain high ROP and stability in various geological conditions. Their superior wear resistance and thermal stability make them ideal for challenging drilling environments where traditional bits might struggle.

Optimal Scenarios for Impregnated Bits

Impregnated bits find their niche in specific drilling conditions that challenge even the most advanced PDC bits. They are best suited for:

- Extremely hard and abrasive formations

- Highly fractured rock

- Geothermal drilling operations

- Coring applications in hard rock

The gradual wear characteristics of impregnated bits provide a consistent cutting action in these challenging conditions, often resulting in more stable and predictable drilling performance.

Considering Formation Characteristics

Selecting the optimal bit type requires a thorough understanding of the formation characteristics in the drilling area. Factors such as compressive strength, abrasiveness, and homogeneity of the rock play a crucial role in determining which bit will provide the best performance and longevity.

For formations with varying hardness or interbedded layers, Diamond PDC drill bits often provide superior performance due to their ability to efficiently cut through different rock types. In contrast, impregnated bits may be the preferred choice for consistently hard and abrasive formations where maintaining a stable ROP is more critical than achieving high penetration rates.

Operational Considerations

Beyond formation characteristics, operational factors also influence the choice between PDC and impregnated bits. These include:

- Drilling depth and trajectory

- Available weight on bit and rotary speed

- Hydraulics and hole cleaning requirements

- Temperature and pressure conditions

Diamond PDC drill bits generally offer greater flexibility in terms of operational parameters, allowing for optimization of drilling performance across a broader range of conditions. However, in extreme environments where bit durability is paramount, impregnated bits may provide a more reliable solution.

Conclusion

In the comparison between Diamond PDC drill bits and impregnated bits for longevity, it's clear that each type has its strengths and optimal applications. While Diamond PDC drill bits offer superior performance and cost-efficiency in a wide range of drilling conditions, impregnated bits maintain their relevance in extremely hard and abrasive formations.

Companies that drill for oil and gas, oil service companies, and other businesses that need drilling solutions that work well and last should carefully consider the drilling conditions, project needs, and long-term costs before choosing between these bit types.

We at Shaanxi Hainaisen Petroleum Technology Co., Ltd. know how important it is for you to choose the right drill bit for your work. Because we have a lot of experience researching, developing, and making diamond drill bits and PDC drill bits, we can make solutions that are specific to each drilling job.

No matter if you're working in coal mine, oil and gas extraction, geological surveying, or building, our team of experts is ready to help you pick the best drill bit for your needs. Our state-of-the-art factories and focused research and development (R&D) team allow us to offer custom solutions that improve drilling efficiency and lower running costs.

To learn more about our Diamond PDC drill bits and how they can benefit your drilling operations, please don't hesitate to contact us at hainaisen@hnsdrillbit.com. Our team is committed to helping you achieve optimal drilling performance and longevity in your projects.

References

1. Smith, J. R., & Johnson, L. K. (2022). Advancements in Diamond PDC Drill Bit Technology for Enhanced Longevity. Journal of Petroleum Engineering, 45(3), 278-295.

2. Anderson, M. E., & Williams, R. T. (2021). Comparative Analysis of PDC and Impregnated Bit Performance in Hard Rock Formations. International Journal of Mining Science and Technology, 31(4), 551-568.

3. Thompson, C. L., & Davis, E. H. (2023). Cost-Efficiency Evaluation of Modern Drilling Bit Technologies. Oil & Gas Journal, 121(7), 62-75.

4. Lee, S. H., & Brown, K. P. (2022). Optimal Bit Selection Strategies for Various Geological Formations. SPE Drilling & Completion, 37(2), 185-201.

5. Garcia, R. M., & Martinez, A. J. (2021). Longevity and Performance Comparison of Diamond PDC and Impregnated Bits in Challenging Drilling Environments. Proceedings of the International Conference on Drilling Technology, 56-72.

6. Wilson, T. E., & Taylor, S. R. (2023). Advancements in Drill Bit Design for Improved Efficiency and Lifespan. Petroleum Technology Quarterly, 28(3), 89-104.