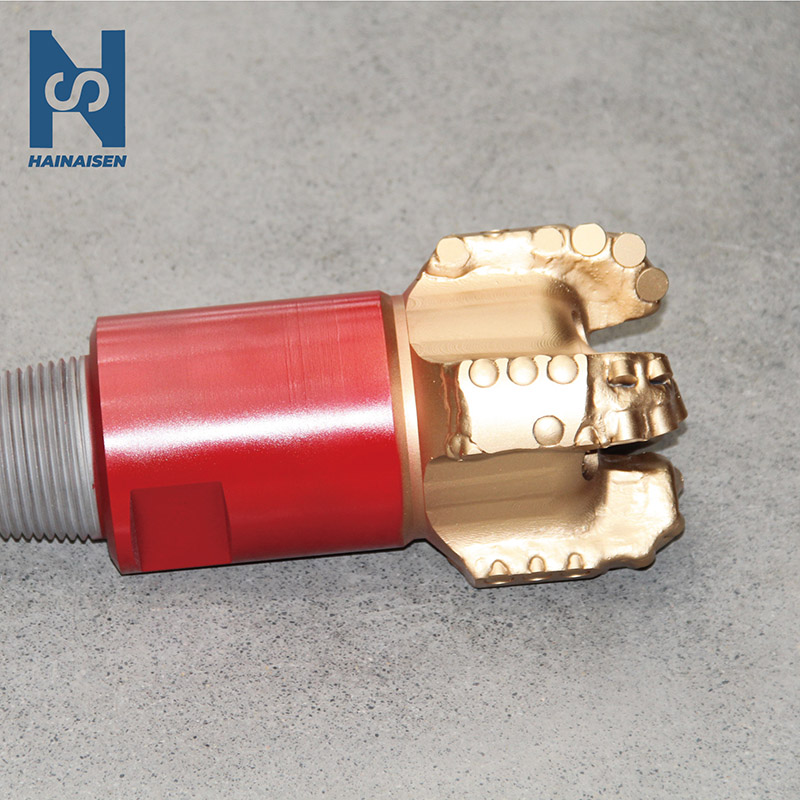

4 Blade PDC Bit

Bit size: 140mm

Number of blade:4

Number of nozzle:4

Connection: 3-1/2 REG.PIN

(customized)

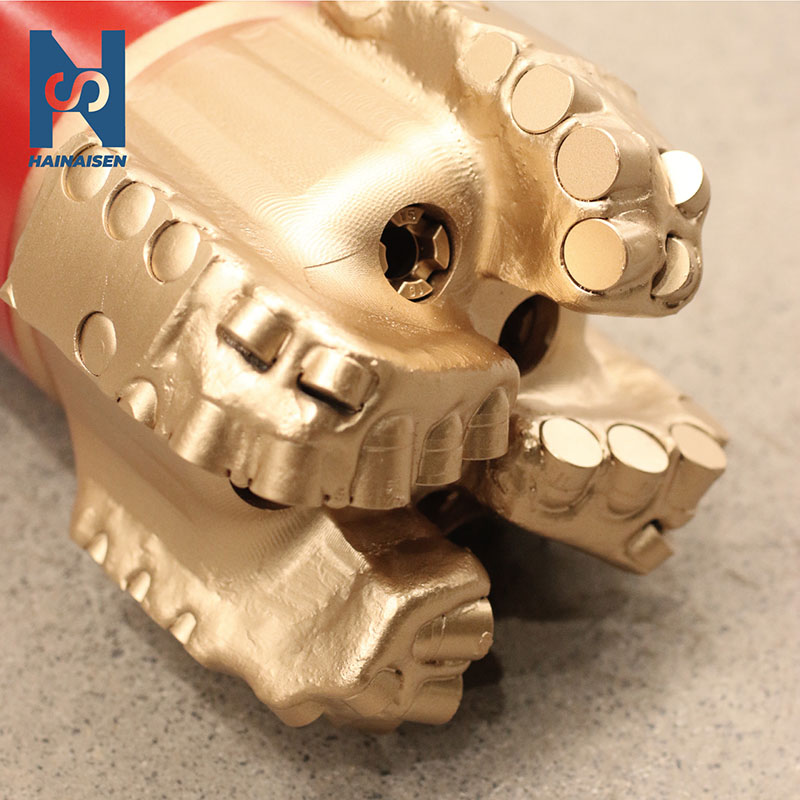

Total number of PDC cutter : 24

PDC Cutter size: 13mm/16mm

Net weight: 12kg

Applicable strata: Level 1-12

Minimum Order Quantity: 10 pieces

Price: To be negotiable

Packaging Details: customized

Delivery Time: 5-7 business days

Payment Terms: T/T, L/C

- Product Description

4 Blade PDC Bit: High-Performance Drilling Solution

SHAANXI HAINAISEN INTELLIGENT EQUIPMENT MANUFACTURING CO.,LTD is a leading manufacturer and supplier of 4 Blade PDC Bits. Our cutting-edge technology and decades of industry expertise allow us to produce high-quality, efficient drilling tools. Our products offer superior performance, durability, and cost-effectiveness for various drilling applications.

Why Choose Our 4 Blade PDC Bit?

- Advanced PDC cutter technology for enhanced drilling efficiency

- Optimized blade design for improved cutting action and debris removal

- Heat and impact-resistant materials for extended bit life

- Customizable options to meet specific drilling requirements

- Rigorous quality control ensuring consistent performance

- Competitive pricing without compromising on quality

Applications

Our 4 Blade PDC Bits are versatile tools suitable for various industries and drilling conditions:

- Oil and Gas Exploration: Ideal for both onshore and offshore drilling operations

- Coal Mining: Efficient for coal seam exploration and extraction

- Water Well Drilling: Perfect for drilling deep water wells in various soil types

- Geothermal Energy: Suitable for creating geothermal wells

- Mineral Exploration: Effective for hard rock drilling in mineral prospecting

- Construction: Used in foundation drilling and tunnel boring operations

Customization Service

We understand that every drilling project has unique challenges. That's why we offer tailored product solutions to meet your specific needs. Our experienced engineers work closely with clients to design and manufacture custom bits that optimize performance for your particular geological conditions and drilling parameters.

Material

Our products are crafted using premium materials:

- High-grade steel body for durability and strength

- Advanced PDC cutters for superior cutting efficiency

- Tungsten carbide matrix for enhanced wear resistance

- Special coating options for improved heat and abrasion resistance

Quality Control

At HAINAISEN, quality is our top priority. We employ a rigorous quality control process:

- Strict material selection and testing

- Precision manufacturing with advanced CNC machinery

- Comprehensive performance testing before shipment

- ISO 9001:2015 certified quality management system

Why Choose HAINAISEN

- 10+ years of industry experience

- Strong R&D capabilities

- Modern manufacturing facilities

- Experienced technical support team

- Competitive pricing and flexible terms

- Commitment to customer satisfaction

Shipment Samples

We offer sample products for testing and evaluation. Contact us to discuss your requirements and arrange for a sample shipment.

Packaging and Transportation

Our products are carefully packaged in sturdy wooden cases to ensure safe transportation. We work with reliable logistics partners to deliver your order efficiently and securely.

Transaction Feedback

We value customer feedback and continuously strive to improve our products and services. After each transaction, we welcome your comments and suggestions to help us serve you better.

After-Sales Service

Our commitment doesn't end with the sale. We offer comprehensive after-sales support:

- Technical consultation

- Performance optimization advice

- Prompt response to inquiries

- Warranty support

Qualification Certification

HAINAISEN holds several industry certifications, including:

- ISO 9001:2015 Quality Management System

- High-tech Enterprise Certification

- Various product patents and certifications

FAQ

Q: What is the lifespan of a product?

A: The lifespan varies depending on drilling conditions, but our bits typically last 30-50% longer than conventional bits.

Q: Can your products be used in high-temperature environments?

A: Yes, our bits are designed to withstand high temperatures common in deep drilling operations.

Q: Do you offer technical support for bit selection?

A: Absolutely. Our experienced engineers can help you choose the right bit for your specific drilling requirements.

Q: What's the lead time for custom products?

A: Lead times for custom bits typically range from 2-4 weeks, depending on complexity and quantity.

Q: Are your products suitable for horizontal drilling?

A: Yes, our bits are designed to perform well in both vertical and horizontal drilling applications.

Contact Us

For more information about our 4 Blade PDC Bits or to discuss your drilling needs, please contact us at hainaisen@hnsdrillbit.com.

VIEW MOREDiamond PDC Drill Bit

VIEW MOREDiamond PDC Drill Bit VIEW MOREFive Wing PDC Bit For Hard Rock Drilling

VIEW MOREFive Wing PDC Bit For Hard Rock Drilling VIEW MORE5 Blades Steel Body High Performance PDC Rock Drill Bits

VIEW MORE5 Blades Steel Body High Performance PDC Rock Drill Bits VIEW MOREHigh Performance 5 Cutter PDC Bit

VIEW MOREHigh Performance 5 Cutter PDC Bit VIEW MORE5 Blade Matrix Body PDC Drill Bits

VIEW MORE5 Blade Matrix Body PDC Drill Bits VIEW MOREFive Blade PDC Drill Bit

VIEW MOREFive Blade PDC Drill Bit VIEW MORESteel Body PDC Bit 4 Blades

VIEW MORESteel Body PDC Bit 4 Blades VIEW MOREFour Blade PDC Drill Bit

VIEW MOREFour Blade PDC Drill Bit