Unveiling the Science: Matrix Body Advantage

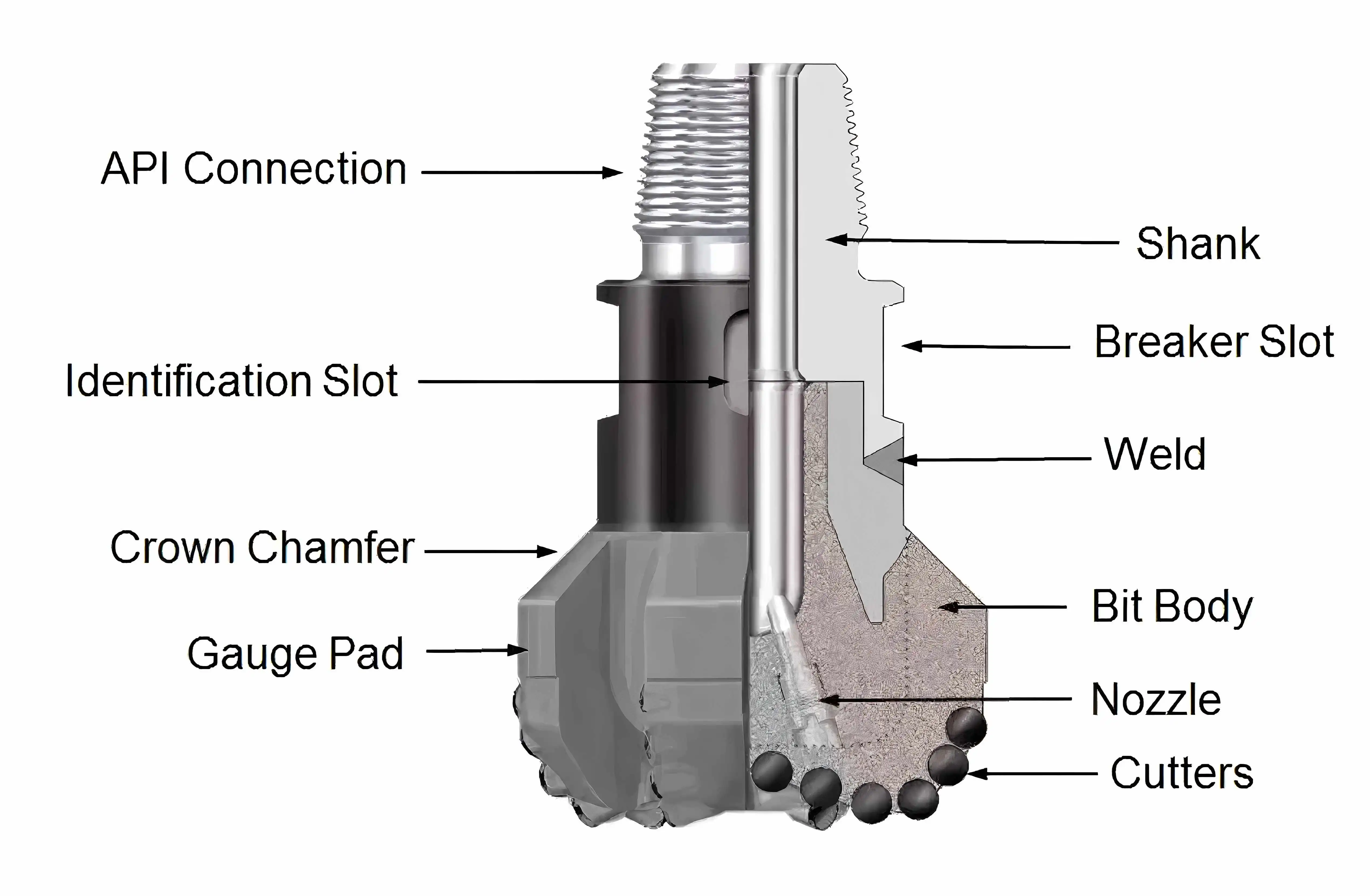

The matrix body of PDC drill bits is a big step forward in the technology of drilling. Matrix bodies are different from traditional steel bodies because they are made up of tungsten carbide bits mixed with a metal binder. This makes a composite material that has special benefits when cutting.

Superior Wear Resistance

One great thing about matrix bodies is that they don't wear down easily. The tungsten carbide particles give the bit unmatched strength and resistance to wear, so it can keep its shape and keep cutting for a long time. Because of this quality, it is very helpful when digging through rough rock layers, where regular steel bodies might wear out quickly.

Enhanced Thermal Stability

It is also true that 5 Blade Matrix Body PDC Drill Bits matrix bodies are more thermally stable than steel bodies. Because the matrix material is made up of different parts, it can better get rid of heat during cutting. This better heat control keeps the cutter from breaking too soon and makes the drill bit last longer, even in high-temperature situations that are common in deep drilling.

Customizable Properties

The flexibility of matrix bodies to adapt their characteristics to particular drilling needs is another important benefit. Manufacturers may fine-tune the bit's properties by varying the size and composition of the tungsten carbide particles as well as the kind and quantity of metallic binder utilized. A degree of adaptability that is hard to get with conventional steel bodies is made possible by this modification, which enables optimal performance in a variety of formation types and drilling situations.

Improved Hydraulics

Additionally, more complex and effective hydraulic designs are made possible by the matrix body architecture. Cuttings evacuation and bit cooling are enhanced by the flexibility to design intricate internal fluid passageways and nozzle arrangements. This increased hydraulic efficiency lowers the chance of bit balling in sticky formations and improves overall drilling performance.

5 Blades: Optimizing Drilling Efficiency and Stability

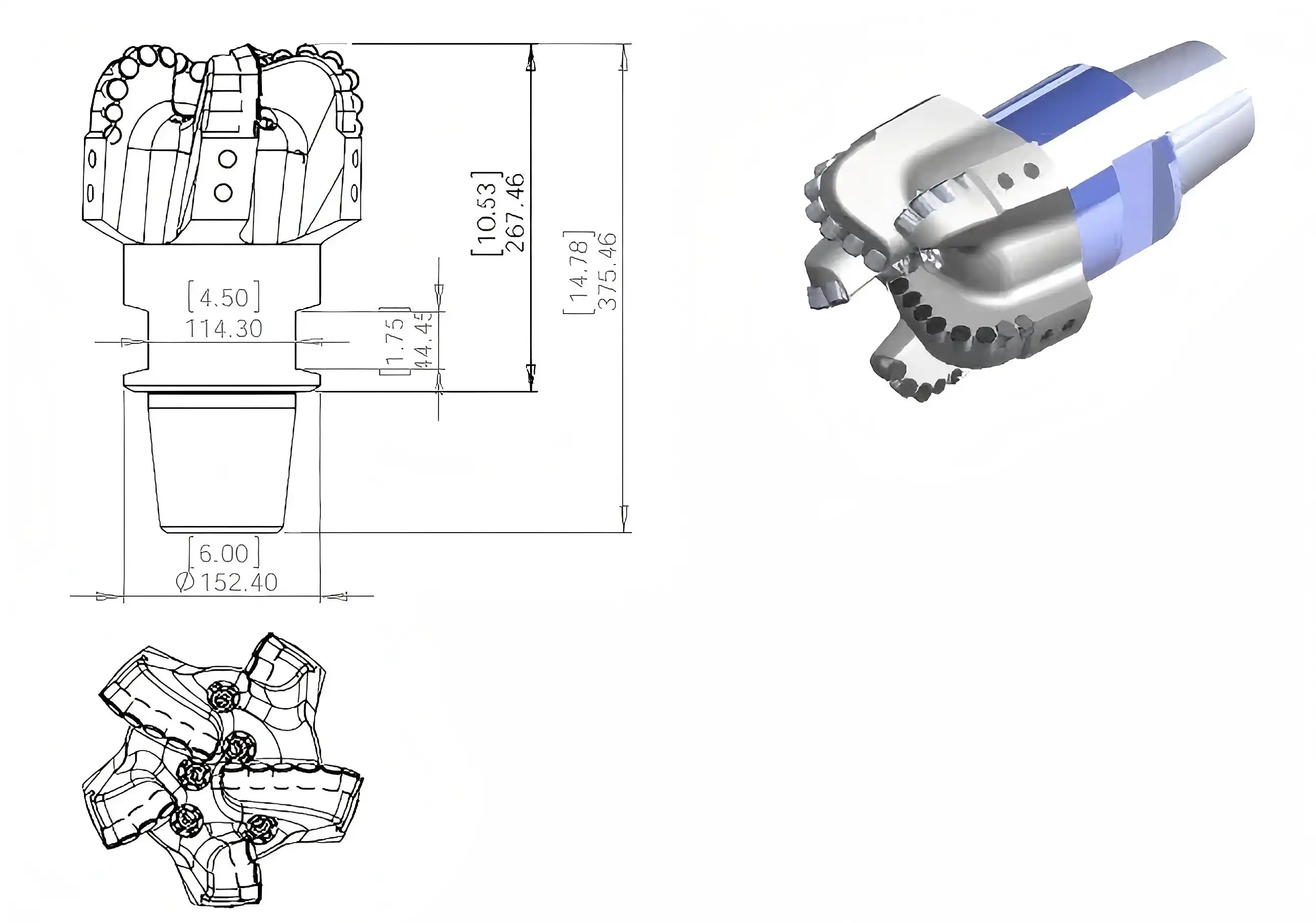

The 5 Blade Matrix Body PDC Drill Bits represent a carefully engineered solution that balances cutting efficiency with stability and durability. The choice of a five-blade configuration is not arbitrary but rather the result of extensive research and field testing to optimize drilling performance across a wide range of applications.

Optimized Cutting Structure

The five-blade design provides an ideal balance between aggressive cutting action and bit stability. Each blade is strategically positioned to maximize coverage of the borehole bottom while maintaining sufficient space between blades for efficient cuttings evacuation. This optimized cutting structure results in faster penetration rates and more consistent drilling performance compared to bits with fewer blades.

Enhanced Stability and Reduced Vibration

The five-blade configuration's capacity to improve bit stability and lessen damaging vibrations during drilling operations is one of its main benefits. Bit spin and stick-slip phenomena, which can cause early bit wear and decreased drilling efficiency, are lessened by the regularly spaced blade configuration. 5 Blade Matrix Body PDC Drill Bits help to straighten wellbores and increase overall drilling accuracy by preserving a more stable drilling platform.

Improved Weight Distribution

Additionally, the bit face's weight distribution is improved by the five-blade design. By distributing the weight evenly, localized wear may be avoided and all PDC cutters can be used efficiently during the drilling operation. Longer bit life and a more constant penetration rate are the outcomes, especially in difficult formations.

Optimized Fluid Dynamics

The ideal channels for drilling fluid flow are created by the distance between the five blades. Better cutting evacuation, less bit balling, and effective cooling of the PDC cutters are all made possible by this improved fluid dynamics. Long-term cutting efficiency and a lower chance of bit damage from overheating or clogging are the outcomes.

Cost-Effectiveness: Long-Term Benefits of Matrix PDC Bits

While the initial investment in 5 Blade Matrix Body PDC Drill Bits for sale may be higher than traditional steel body bits, the long-term cost benefits make them an economically advantageous choice for drilling operations.

Extended Bit Life

The superior wear resistance of matrix bodies, combined with the optimized five-blade design, significantly extends the operational life of these drill bits. This longevity translates to fewer bit trips, reduced downtime, and lower overall drilling costs. In challenging environments where bit wear is a critical factor, the extended life of matrix PDC bits can result in substantial savings over the course of a drilling project.

Improved Drilling Efficiency

Faster penetration rates and more reliable drilling results are a result of the 5 Blade Matrix Body PDC Drill Bits' improved stability and cutting efficiency. Especially in large-scale drilling operations, this enhanced efficiency might result in considerable time savings. In addition to lowering direct operating costs, shorter drilling times also save related expenditures like rig time and staffing.

Reduced Tripping Frequency

Because matrix PDC bits are long-lasting and perform well over time, drilling operations require fewer bit replacements. Every time a drill bit needs to be changed, time and resources are wasted. The efficiency of the project is increased by streamlining processes and lowering the frequency of these visits using matrix PDC bits.

Versatility Across Formations

These drill bits are more useful because they can have their matrix bodies changed to fit different types of rock. Because of this, it is not necessary to change bits as often when cutting through different layers of rock, which further improves working efficiency and cuts costs.

Lower Environmental Impact

Matrix PDC bits leave less of an impact on the world because they last longer and work more efficiently. Less material is used and less trash is made over the course of a drilling job when bits are replaced less often. This is becoming more and more important as the business works on drilling methods that are sustainable and good for the earth.

Conclusion

When it comes to long-term performance and cost-effectiveness, it's easy to see which is better: matrix or steel body PDC drill bits. The longevity, efficiency, and adaptability of 5 Blade Matrix Body PDC Drill Bits make them very appealing. This means that they are very useful for a lot of different drilling tasks and save a lot of money in the process.

Are you ready to elevate your drilling operations with cutting-edge technology? Shaanxi Hainaisen Petroleum Technology Co., Ltd. specializes in the research, development, and production of high-performance PDC drill bits tailored to your specific needs. Whether you're engaged in oil and gas extraction, coal mining, or geological surveying, our expert team and state-of-the-art 3,500m² facility are equipped to deliver customized drilling solutions that maximize efficiency and minimize costs. Experience the difference that advanced engineering and precision manufacturing can make in your drilling projects. Contact us today at hainaisen@hnsdrillbit.com to discuss how our 5 Blade Matrix Body PDC Drill Bits can transform your drilling operations and drive your success.

References

1. Zhang, J., & Li, X. (2019). Advances in matrix-body PDC bit technology for oil and gas drilling. Journal of Petroleum Science and Engineering, 172, 1-12.

2. Wang, L., et al. (2020). Experimental study on the effect of blade number on PDC bit performance. International Journal of Rock Mechanics and Mining Sciences, 126, 104194.

3. Cummins, T., & Pruitt, J. (2018). Matrix vs. steel: A comparative analysis of PDC bit body materials. SPE Drilling & Completion, 33(02), 145-157.

4. Niu, S., et al. (2021). Optimization of five-blade PDC bit design using computational fluid dynamics. Journal of Petroleum Science and Engineering, 196, 107661.

5. Beaton, R., & Cheng, L. (2017). Economic analysis of matrix-body PDC bits in challenging drilling environments. SPE Economics & Management, 9(03), 102-112.

6. Gao, D., et al. (2020). Wear mechanism and performance improvement of matrix-body PDC bits. Wear, 458-459, 203393.