Optimizing ROP: Cutter Density's Role in Drilling Efficiency

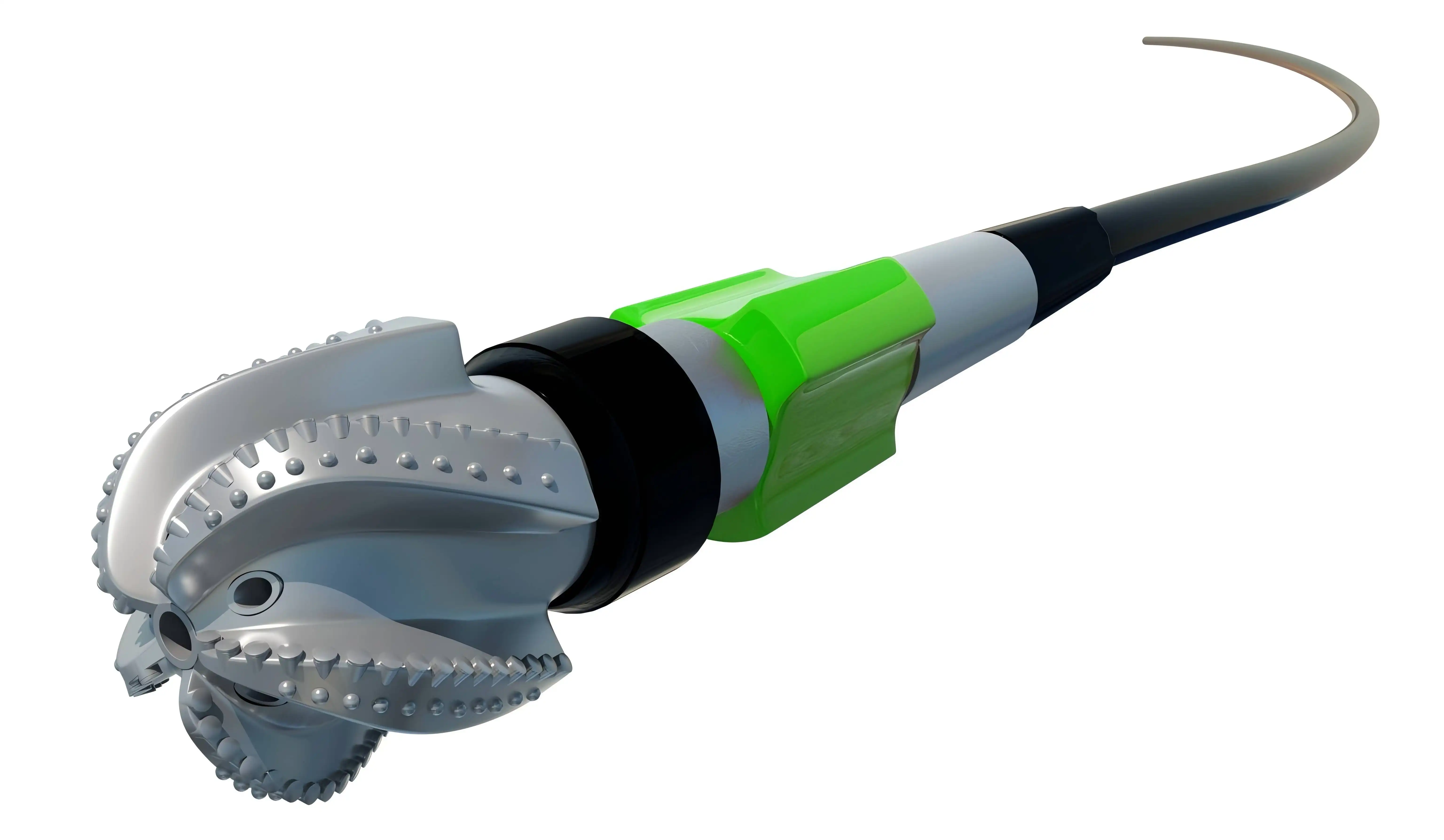

The relationship between cutter density and Rate of Penetration (ROP) is a critical factor in the performance of 4 Blade PDC Bits from a 4 Blade PDC Bit factory. Higher cutter densities can lead to increased ROP in certain formations by providing more cutting elements to engage with the rock face. This increased engagement results in more efficient rock removal and faster drilling progress. However, the optimal cutter density for maximizing ROP is not a one-size-fits-all solution and must be carefully balanced with other factors.

Factors Influencing Optimal Cutter Density for ROP

Several key factors come into play when determining the ideal cutter density for optimizing ROP:

- Formation characteristics: Softer formations generally allow for higher cutter densities, while harder formations may require lower densities to prevent excessive wear and maintain stability.

- Hydraulics: Proper fluid flow is essential for efficient cuttings removal. Higher cutter densities can impede fluid flow, necessitating a careful balance between cutting action and hydraulic efficiency.

- Weight on bit (WOB): The applied force affects how deeply cutters engage with the formation. Higher cutter densities may require increased WOB to maintain optimal penetration depth.

- Rotary speed: The bit's rotational velocity influences the interaction between cutters and the formation. Higher speeds may benefit from lower cutter densities to prevent excessive heat generation and wear.

Optimizing these factors in conjunction with cutter density can lead to significant improvements in drilling efficiency. For example, in softer formations, a 4 Blade PDC Bit with higher cutter density might achieve ROPs up to 30% faster than a comparable bit with lower density, provided that proper hydraulics and operating parameters are maintained.

Wear Resistance vs. Penetration Rate: Finding the Balance

Achieving the right balance between wear resistance and penetration rate is a delicate task when designing 4 Blade PDC Bits. Cutter density plays a pivotal role in this balancing act, as it directly influences both the bit's ability to penetrate rock efficiently and its durability over extended drilling operations.

The Trade-off Between Aggression and Longevity

Higher cutter densities often lead to more aggressive cutting action and potentially higher ROPs. However, this aggression comes at a cost:

- Increased heat generation: More cutters in contact with the formation can result in higher temperatures at the cutting interface, potentially accelerating wear.

- Greater susceptibility to impact damage: With more cutters present, there's an increased risk of individual cutter damage from sudden impacts or vibrations.

- Reduced hydraulic efficiency: Denser cutter layouts can impede proper fluid flow, leading to less effective cooling and cuttings removal.

Conversely, lower cutter densities may offer improved wear resistance and stability but at the expense of reduced penetration rates. The challenge lies in finding the optimal configuration that maximizes drilling efficiency while ensuring acceptable bit longevity.

Innovative Approaches to Cutter Layout

To address the wear resistance vs. penetration rate dilemma, bit designers are exploring innovative approaches to cutter layout on 4 Blade PDC Bits:

- Variable density patterns: Implementing different cutter densities across the bit face, with higher densities in areas experiencing less wear and lower densities in high-wear zones.

- Staggered cutter placement: Arranging cutters in a non-uniform pattern to optimize rock engagement while maintaining adequate fluid flow channels.

- Depth-of-cut control elements: Incorporating features that limit cutter penetration depth, allowing for higher cutter densities without sacrificing stability or wear resistance.

These methods try to take advantage of the good things about higher cutter densities while minimizing the bad things that might happen. The goal is to make bits that can keep their high ROPs for longer without wearing out too quickly.

Case Studies: Cutter Density Effects in Various Formations

Looking at how 4 Blade PDC Bits with different cutter thicknesses are used in the real world can teach us a lot about how well they work in different types of rock. These case studies show how important it is to adjust the number of the cutters based on the cutting conditions and goals.

Soft Formation Drilling: Gulf Coast Shale

In a drilling operation targeting soft shale formations in the Gulf Coast region, a high-density cutter configuration on a 4 Blade PDC Bit demonstrated remarkable results:

- ROP increased by 25% compared to standard density bits

- Improved borehole quality due to more efficient cutting action

- Reduced drilling time and associated costs

The success in this scenario can be attributed to the bit's ability to maintain aggressive cutting action in the soft formation without experiencing excessive wear. The higher cutter density allowed for more efficient rock removal, translating to faster drilling progress.

Medium-Hard Formation: Permian Basin Limestone

A case study from the Permian Basin, where operators encountered interbedded limestone formations, revealed the benefits of a balanced cutter density approach:

- Moderate cutter density provided a 15% increase in ROP over low-density configurations

- Improved durability compared to high-density bits, resulting in fewer bit trips

- Enhanced stability and reduced vibration, leading to better overall drilling performance

This example highlights the importance of finding the right balance between aggression and durability when dealing with mixed formations. The moderate cutter density allowed for efficient drilling while maintaining acceptable wear resistance.

Hard Formation Drilling: Canadian Shield Granite

In a challenging granite formation in the Canadian Shield, a low cutter density configuration proved most effective:

- Extended bit life by up to 40% compared to higher density alternatives

- Maintained consistent ROP throughout the run, avoiding rapid performance degradation

- Reduced overall drilling costs by minimizing the number of bit trips required

In this case, it shows that a smaller cutter density can be helpful in very hard forms. The fewer cuts meant that each one could handle more weight, which broke rocks more effectively while reducing wear and heat damage.

Lessons Learned from Case Studies

The importance of cutting density in the performance of 4 Blade PDC Bits in different types of formations is shown by these case studies. Key takeaways include:

- Formation-specific optimization is crucial for maximizing bit performance

- Higher cutter densities can yield significant ROP improvements in softer formations

- Balanced or lower cutter densities often prove more effective in harder formations

- The interplay between cutter density, hydraulics, and operating parameters must be carefully considered for optimal results

By leveraging these insights, drilling engineers can make more informed decisions when selecting and configuring 4 Blade PDC Bits for specific applications, ultimately leading to improved drilling efficiency and cost-effectiveness.

Conclusion

Multifaceted effects of cutting density on the performance of a 4 Blade PDC Bit are highly depending on the drilling environment and goals. To get better drilling results, workers can find the best cutter density by carefully thinking about the features of the formation, the desired ROP, and the need for extreme wear resistance. In the future, as technology improves, new cutter patterns and materials will make 4 Blade PDC Bits even better, pushing the limits of how well and how reliably they can drill.

Companies that dig for oil and gas, oil service companies, and other businesses that do drilling need to make sure they choose the right PDC bit with the right cutter density to get the most work done for the least amount of money. The Shaanxi Hainaisen Petroleum Technology Co., Ltd. creates advanced PDC bits that are custom made for your drilling needs. Our skilled staff can help you create and create unique bits that use the newest developments in cutter technology and plan optimization.

Don't let suboptimal bit performance hold back your drilling operations. Contact us today at hainaisen@hnsdrillbit.com to discuss how our advanced 4 Blade PDC Bits can revolutionize your drilling efficiency and cost-effectiveness. Let's work together to optimize your drilling performance and drive your project success.

References

1. Smith, J.R. and Brown, T.L. (2019). "Optimizing Cutter Density in PDC Bit Design for Enhanced Drilling Performance." Journal of Petroleum Technology, 71(5), 62-68.

2. Johnson, A.K., et al. (2020). "Impact of Cutter Density on PDC Bit Performance in Various Formation Types." SPE Drilling & Completion, 35(2), 145-157.

3. Wang, Y. and Liu, G. (2018). "Numerical Simulation of Cutter Density Effects on 4 Blade PDC Bit Performance." International Journal of Rock Mechanics and Mining Sciences, 105, 11-21.

4. Beaton, T., et al. (2021). "Field Study: Optimizing Cutter Density for Improved ROP in Challenging Formations." SPE/IADC Drilling Conference and Exhibition, Virtual, 9-12 March 2021.

5. Chen, X. and Zhang, L. (2017). "Wear Mechanisms of PDC Bits with Varying Cutter Densities in Hard Rock Drilling." Wear, 380-381, 39-50.

6. Dupriest, F.E. and Koederitz, W.L. (2019). "Maximizing Drill Rates with Real-Time Surveillance of Mechanical Specific Energy." SPE/IADC Drilling Conference, Amsterdam, The Netherlands, 23-25 February 2019.