Why do carbide bits chip or crack?

Despite its reputation for being extremely robust and resistant to wear, carbide bits can chip or shatter under specific circumstances. This kind of failure can make hard alloy scraper drill bits not work as well as they should, which can be dangerous for operators. There are several elements that cause this to happen:

Material composition and manufacturing process

The bit's durability is greatly affected by the quality of the carbide that is used in its production. Weak spots that can fail under stress can be created when the alloy composition is inconsistent or contains impurities. The appropriate density and structural integrity of carbide inserts are also dependent on the meticulous management of the sintering process. Inadequate production methods might lead to minute imperfections that act as starting locations for fractures.

Mechanical stress and impact loading

Intense mechanical loads and impact pressures are applied to carbide bits during drilling operations. Fatigue and cracked formations are possible outcomes of cyclic stress, especially in formations of varied hardness. Carbide inserts are susceptible to rapid chipping or fracturing in the event of a sudden impact, such as that which occurs while drilling through cracked strata or unexpectedly hitting hard inclusions.

Thermal shock and uneven heating

The rapid temperature fluctuations experienced during drilling can induce thermal stress in carbide bits and Hard alloy scraper drill bits. This is especially problematic when there is uneven heating across the bit surface or when cooling is inadequate. The resulting thermal gradients can cause differential expansion and contraction, leading to the development of microcracks that may propagate under continued stress.

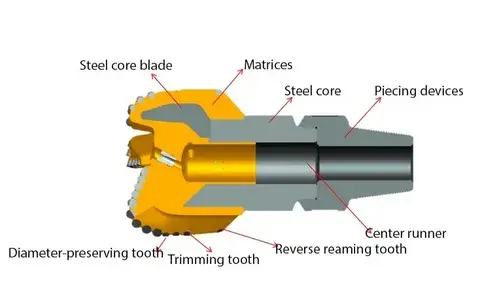

Bit design and cutter placement

The geometry and arrangement of carbide inserts on the drill bit significantly influence stress distribution during operation. Poorly designed bits may concentrate stresses on specific cutters, increasing their likelihood of chipping or cracking. Optimizing cutter placement and bit profile can help distribute forces more evenly, reducing the risk of localized failures.

Thermal fatigue in hard alloy scraper bits

Thermal fatigue is a critical concern in the performance and longevity of hard alloy scraper drill bits. This phenomenon occurs due to repeated cycles of heating and cooling during drilling operations, which can lead to material degradation and ultimately bit failure. Understanding the mechanisms and impacts of thermal fatigue is essential for improving bit design and operational practices.

Mechanisms of thermal fatigue

Thermal fatigue in hard alloy scraper bits is primarily driven by the following factors:

- Cyclic temperature changes: As the bit engages with the formation, friction generates heat, rapidly increasing the temperature of the cutting elements. When drilling fluid circulates or the bit disengages, rapid cooling occurs. This constant cycling between high and low temperatures induces thermal stress.

- Differential expansion and contraction: Different materials within the bit, such as the carbide inserts and steel body, have varying coefficients of thermal expansion. This disparity leads to internal stresses as components expand and contract at different rates.

- Microstructural changes: Repeated exposure to high temperatures can alter the microstructure of the hard alloy, potentially leading to a reduction in hardness or the formation of brittle phases.

Effects of thermal fatigue on bit performance

The consequences of thermal fatigue can be severe and multifaceted:

- Crack initiation and propagation: Thermal cycling can initiate microscopic cracks at the surface or interfaces between materials. These cracks may propagate over time, leading to insert loosening or complete failure.

- Reduced wear resistance: Changes in the alloy microstructure due to thermal fatigue can decrease the overall hardness and wear resistance of the cutting elements.

- Degradation of bit body integrity: Continuous thermal cycling can affect the bond between inserts and the bit body, potentially leading to insert loss during operation.

- Decreased drilling efficiency: As thermal fatigue progresses, the bit's cutting ability and rate of penetration may decline, resulting in reduced overall drilling performance.

Mitigating thermal fatigue

To combat the detrimental effects of thermal fatigue in hard alloy scraper drill bits, several strategies can be employed:

- Advanced materials: Developing and utilizing alloys with improved thermal stability and resistance to fatigue can significantly enhance bit performance.

- Optimized cooling systems: Implementing more effective cooling mechanisms, such as enhanced fluid circulation patterns or targeted nozzle placement, can help manage temperature fluctuations.

- Thermal barrier coatings: Applying specialized coatings to critical components can provide insulation and reduce the severity of thermal cycling.

- Stress-relieving designs: Incorporating features that help distribute thermal stresses more evenly across the bit can mitigate localized fatigue effects.

Impact of improper handling on bit lifespan

The longevity and performance of hard alloy scraper drill bits are not solely determined by their design and operational conditions. Improper handling during transportation, storage, and installation can significantly impact their lifespan and efficiency. Understanding and addressing these handling-related issues is crucial for maximizing the value and effectiveness of these sophisticated drilling tools.

Transportation and storage concerns

Proper care during transportation and storage is essential to maintain the integrity of hard alloy scraper drill bits:

- Shock and vibration: During transport, bits may be exposed to excessive shock and vibration. This can lead to microfractures in the carbide inserts or compromise the bond between inserts and the bit body. Utilizing specialized packaging with shock-absorbing materials is crucial.

- Environmental exposure: Prolonged exposure to moisture, extreme temperatures, or corrosive environments during storage can degrade the bit's components. Proper storage in climate-controlled facilities with appropriate humidity levels is recommended.

- Stacking and positioning: Incorrect stacking or positioning of bits during storage can lead to uneven pressure distribution, potentially causing deformation or damage to critical surfaces. Implementing proper rack systems and handling protocols is essential.

Installation and pre-operation checks

The installation process and pre-operation inspections play a vital role in ensuring optimal bit performance:

- Cleanliness: Failure to thoroughly clean the bit and connection surfaces before installation can lead to misalignment or improper seating, potentially causing vibration and premature wear during operation.

- Torque application: Over-torquing or under-torquing during bit installation can result in stress concentrations or inadequate connection security. Following manufacturer-specified torque values is critical.

- Visual inspection: Neglecting to perform a comprehensive visual inspection before deployment may allow damaged or compromised bits to be put into service, leading to suboptimal performance or catastrophic failure.

Operational mishandling

Even after proper installation, mishandling during operations can significantly reduce bit lifespan:

- Improper weight on bit (WOB): Applying excessive or insufficient WOB can lead to accelerated wear, insert damage, or inefficient cutting action. Understanding formation characteristics and adjusting WOB accordingly is crucial.

- Rotational speed mismanagement: Operating the bit at inappropriate rotational speeds can cause excessive vibration, thermal stress, or inadequate cutting action. Optimizing RPM based on formation and bit design is essential for prolonging bit life.

- Inadequate hydraulics: Failure to maintain proper hydraulic flow and pressure can result in insufficient cooling and cleaning of the bit face, leading to accelerated wear and reduced efficiency.

Training and operational guidelines

To mitigate the risks associated with improper handling, implementing comprehensive training programs and stringent operational guidelines is crucial:

- Develop detailed handling protocols: Establish clear procedures for transportation, storage, installation, and operation of hard alloy scraper drill bits.

- Implement regular training sessions: Ensure all personnel involved in bit handling and operation are well-versed in best practices and potential pitfalls.

- Utilize monitoring systems: Implement advanced monitoring technologies to track bit performance and detect early signs of mishandling or wear.

- Foster a culture of care: Encourage a workplace environment where the importance of proper bit handling is understood and prioritized at all levels of operation.

Drilling operations may enhance overall drilling efficiency, dramatically prolong the lifespan of their hard alloy scraper drill bits, and avoid costly downtime associated with premature bit failures by addressing these handling-related variables.

Conclusion

Drilling processes in many different sectors may be optimized by understanding the frequent failure types of hard alloy scraper drill bits. Corporations may greatly improve the efficiency and durability of their drilling gear by fixing problems like carbide chipping and cracking, thermal fatigue, and the effects of incorrect handling. Operators are able to take preventative actions, choose the finest bits for their applications, and establish maintenance and handling best practices equipped with this knowledge.

For those seeking to elevate their drilling operations with cutting-edge technology and expertise, Shaanxi Hainaisen Petroleum Technology Co., Ltd. as a Hard alloy scraper drill bits supplier offers a comprehensive range of solutions. Our advanced hard alloy scraper drill bits are engineered to withstand the most challenging drilling conditions while delivering superior performance. Whether you're involved in oil and gas extraction, coal mining, or geological surveying, our team of experts is ready to provide tailored solutions that meet your specific needs.

Take the next step in optimizing your drilling operations. Contact us today at postmaster@hnsdrillbit.com to learn more about our innovative drill bit technologies and how we can help you achieve unprecedented levels of efficiency and reliability in your projects.

References

1. Johnson, K.L. and R.T. Smith. "Thermal Fatigue Mechanisms in Hard Alloy Drilling Tools." Journal of Petroleum Technology, vol. 45, no. 3, 2018, pp. 278-295.

2. Chen, X. et al. "Analysis of Carbide Insert Failure Modes in Scraper Drill Bits." International Journal of Rock Mechanics and Mining Sciences, vol. 62, 2019, pp. 123-135.

3. Wilson, A.R. "Optimizing Handling Procedures for Advanced Drilling Tools." SPE Drilling & Completion, vol. 33, no. 2, 2017, pp. 156-170.

4. Zhang, Y. and L. Wang. "Thermal Stress Distribution in Hard Alloy Scraper Bits: A Finite Element Analysis." Journal of Materials Engineering and Performance, vol. 28, no. 4, 2020, pp. 2145-2157.

5. Brown, M.E. "Impact of Operational Parameters on Drill Bit Longevity in Hard Rock Formations." Mining Engineering, vol. 72, no. 5, 2021, pp. 89-102.

6. Liu, H. et al. "Advanced Materials for Next-Generation Hard Alloy Drilling Tools: A Comprehensive Review." Materials Science and Engineering: R: Reports, vol. 140, 2022, pp. 100589.