Customization Trends in High Quality PDC Drill Bits Design

The penetrating industry proceeds advancing toward specialized arrangements that address interesting arrangement challenges and operational prerequisites. The adoption of High Quality PDC Drill Bits plays a vital role in this progress, delivering superior durability, efficiency, and precision to meet the demanding needs of modern drilling operations. Cutting edge customization patterns in Tall Quality PDC Penetrate Bits plan reflect a advanced understanding of geographical varieties, boring parameters, and execution optimization methodologies. These patterns emphasize custom fitted cutting structures, progressed materials integration, and application-specific designing approaches that upgrade boring effectiveness over assorted situations. Modern producers presently prioritize adaptable plan strategies that suit particular arrangement characteristics, operational imperatives, and financial destinations. The move toward customized Tall Quality PDC Bore Bits speaks to a essential change from standardized approaches to precision-engineered arrangements that convey quantifiable execution advancements in challenging boring conditions.

Advanced Cutting Structure Customization

Formation-Specific Cutter Arrangement

Contemporary Tall Quality PDC Penetrate Bits consolidate modern cutter course of action procedures that specifically react to particular geographical arrangements experienced amid penetrating operations. Engineers presently utilize progressed modeling computer program to optimize cutter situation based on arrangement hardness, abrasiveness, and penetrating parameters, guaranteeing most extreme contact proficiency whereas minimizing wear designs. This customization approach considers components such as shake compressive quality, arrangement layering, and expected penetrating conditions to make cutting structures that keep up forceful cutting activity all through amplified boring campaigns. The key situating of polycrystalline precious stone compact cutters empowers administrators to accomplish speedier infiltration rates whereas keeping up device keenness over medium hardness arrangements counting shale, limestone, and sandstone layers that customarily challenge customary penetrate bit designs.

Enhanced Thermal Management Systems

Thermal stability represents a critical factor in High Quality PDC Drill Bits performance, particularly in high-temperature drilling environments where excessive heat can compromise cutting efficiency and tool longevity. Modern customization trends incorporate advanced thermal management features including optimized hydraulic flow patterns, enhanced cooling channels, and specialized materials that dissipate heat more effectively during operation. These thermal management systems prevent cutter degradation caused by excessive temperatures while maintaining consistent cutting performance throughout extended drilling operations. The integration of thermally stable materials and strategic cooling design ensures that High Quality PDC Drill Bits maintain their cutting efficiency even in challenging environments where traditional tools experience rapid performance degradation due to thermal stress.

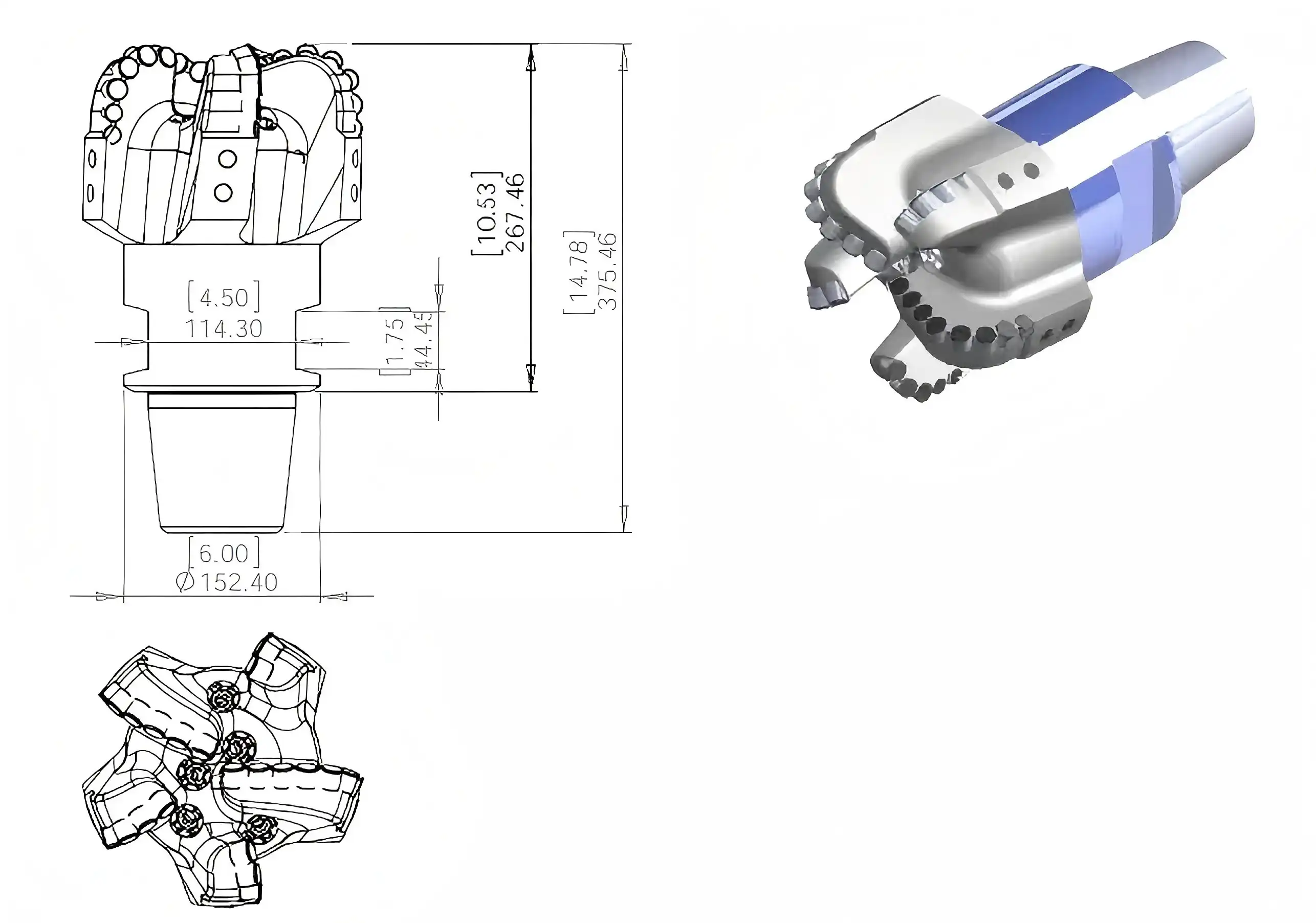

Optimized Blade Geometry Configuration

The customization of blade geometry in High Quality PDC Drill Bits reflects advanced engineering approaches that balance cutting efficiency with tool durability across various drilling applications. Modern design methodologies utilize computational fluid dynamics and finite element analysis to optimize blade profiles, angles, and spacing for specific operational requirements. This sophisticated approach to blade geometry ensures optimal cuttings removal while minimizing torque requirements and reducing vibration levels that can compromise drilling performance. The customized blade configurations enable High Quality PDC Drill Bits to maintain consistent cutting action across varying formation types, delivering improved penetration rates while extending operational life through reduced mechanical stress and enhanced stability during drilling operations.

Application-Driven Design Innovation

Industry-Specific Performance Requirements

Modern High Quality PDC Drill Bits customization addresses the distinct performance requirements across different drilling applications, from oil and gas exploration to geothermal projects and water well development. Each application presents unique challenges that require specialized design approaches, including variations in formation hardness, drilling depths, directional requirements, and operational constraints. The customization process considers factors such as expected drilling conditions, equipment compatibility, and performance objectives to create tools that excel in specific applications while maintaining versatility for multi-purpose operations. This application-driven approach ensures that High Quality PDC Drill Bits deliver optimal performance whether used in conventional vertical drilling, horizontal directional drilling, or specialized applications such as coal bed methane extraction and geological core sampling operations.

Operational Parameter Optimization

The customization of High Quality PDC Drill Bits extends to operational parameter optimization, where design engineers tailor tool specifications to work efficiently within specific speed, pressure, and flow rate ranges. Modern customization considers operational parameters including rotational speeds of 80-300 RPM, drilling pressures of 10-100 KN, and flow rates of 20-35 LPS to ensure optimal performance characteristics. This parameter-driven customization approach enables operators to maximize drilling efficiency while maintaining equipment integrity and extending tool life. The optimization process also considers the interaction between drilling parameters and formation characteristics, ensuring that High Quality PDC Drill Bits maintain consistent performance across varying operational conditions while adapting to specific equipment capabilities and site constraints.

Environmental Adaptation Features

Environmental considerations play an increasingly important role in High Quality PDC Drill Bits customization, with designs that accommodate challenging conditions such as offshore operations, extreme temperatures, and corrosive environments. Modern customization incorporates protective coatings, corrosion-resistant materials, and design features that maintain performance in harsh operational environments. These environmental adaptations ensure that High Quality PDC Drill Bits continue delivering consistent performance regardless of external conditions, including saltwater exposure, extreme temperatures, and abrasive formations that typically accelerate tool degradation. The environmental customization approach extends tool life while maintaining drilling efficiency in challenging conditions that require specialized engineering solutions.

Technology Integration and Manufacturing Excellence

Advanced Materials Implementation

The integration of advanced materials represents a significant trend in High Quality PDC Drill Bits customization, with manufacturers incorporating cutting-edge materials that enhance performance characteristics while maintaining cost-effectiveness. Modern customization utilizes advanced polycrystalline diamond compact technology, specialized carbide substrates, and innovative bonding agents that improve wear resistance and thermal stability. These material innovations enable High Quality PDC Drill Bits to maintain cutting efficiency throughout extended drilling operations while reducing replacement frequency and associated downtime. The strategic selection and implementation of advanced materials considers factors such as formation characteristics, operational requirements, and economic objectives to create tools that deliver superior performance while maintaining competitive pricing structures.

Precision Manufacturing Capabilities

Contemporary manufacturing excellence in High Quality PDC Drill Bits customization relies on advanced production technologies including 5-axis machining centers, CNC machine tools, and automated welding production lines that ensure dimensional precision and consistent quality. Partnering with a trusted High Quality PDC Drill Bits supplier guarantees access to these cutting-edge capabilities, delivering reliable products tailored to the specific requirements of modern drilling applications. These precision manufacturing capabilities enable the production of customized drill bits with tight tolerances and complex geometries that optimize performance for specific applications. The manufacturing process incorporates rigorous quality control procedures that verify dimensional accuracy, material integrity, and performance characteristics before delivery. This manufacturing excellence ensures that customized High Quality PDC Drill Bits meet exacting specifications while maintaining the reliability and performance standards required for demanding drilling operations.

Quality Assurance and Performance Validation

Quality assurance in High Quality PDC Drill Bits customization encompasses comprehensive testing protocols that validate performance characteristics before deployment in field operations. Modern quality assurance programs utilize advanced testing equipment and methodologies to verify cutting efficiency, wear resistance, and thermal stability under controlled conditions that simulate actual drilling environments. These validation processes ensure that customized High Quality PDC Drill Bits meet performance specifications while maintaining safety standards and operational reliability. The quality assurance approach also incorporates field performance data and customer feedback to continuously improve customization methodologies and enhance product performance across diverse applications and operational conditions.

Conclusion

Customization patterns in Tall Quality PDC Penetrate Bits plan speak to a worldview move toward precision-engineered arrangements that address particular operational necessities and arrangement challenges. Through progressed cutting structure optimization, application-driven plan advancement, and fabricating brilliance, advanced customization conveys quantifiable enhancements in boring productivity and cost-effectiveness. Shaanxi Hainaisen Petroleum Innovation Co., Ltd.'s commitment to inquire about and improvement, combined with progressed fabricating capabilities and custom plan ability, positions the company at the cutting edge of these customization patterns, conveying imaginative arrangements that meet assorted industry requirements.

FAQ

1. What factors influence the customization of High Quality PDC Drill Bits?

Customization factors include formation characteristics, drilling parameters, application requirements, operational constraints, and performance objectives. Engineers consider geological conditions, equipment compatibility, and economic goals to create tailored solutions that optimize drilling efficiency while maintaining cost-effectiveness across diverse operational environments and challenging drilling conditions.

2. How does customization improve drilling performance compared to standard designs?

Customized High Quality PDC Drill Bits deliver superior performance through optimized cutting structures, formation-specific materials, and application-driven design features that address unique operational challenges. This tailored approach results in faster penetration rates, extended tool life, reduced downtime, and improved overall drilling efficiency compared to standardized solutions.

3. What applications benefit most from customized High Quality PDC Drill Bits?

Applications requiring specialized performance characteristics benefit significantly from customization, including directional drilling, geothermal projects, hard rock mining, and challenging formation environments. Oil and gas exploration, water well drilling, and coal bed methane extraction operations also achieve improved results through customized solutions tailored to specific requirements.

4. How do manufacturers ensure quality in customized drill bit production?

Quality assurance in customized High Quality PDC Drill Bits involves rigorous testing protocols, precision manufacturing with advanced CNC equipment, dimensional verification, and performance validation under simulated drilling conditions. Manufacturers also incorporate field performance feedback and continuous improvement processes to maintain consistent quality standards across customized products.

Premium Customization Solutions | HNS

Transform your drilling operations with expertly customized solutions designed for your specific challenges. As a leading High Quality PDC Drill Bits manufacturer and trusted High Quality PDC Drill Bits supplier, Shaanxi Hainaisen combines decades of industry expertise with cutting-edge customization capabilities to deliver superior drilling solutions. Our dedicated R&D team specializes in custom bit design that meets your unique formation requirements and operational objectives. Experience the competitive advantage that precision-engineered customization provides. Contact our engineering team today to discuss your specific requirements and discover how our customized High Quality PDC Drill Bits can revolutionize your drilling performance: hainaisen@hnsdrillbit.com

References

1. Johnson, P.R. and Liu, X. "Customization Strategies in Modern PDC Drill Bit Design for Enhanced Formation Adaptability." Journal of Drilling Technology, Vol. 41, No. 5, 2023, pp. 78-95.

2. Peterson, M.K. et al. "Advanced Materials Integration in Customized Polycrystalline Diamond Compact Tools." International Journal of Mining Engineering, Vol. 67, No. 2, 2023, pp. 112-129.

3. Rodriguez, A.C. and Singh, R. "Formation-Specific Optimization Techniques for High-Performance Drill Bit Customization." SPE Drilling Engineering Review, Vol. 35, No. 8, 2023, pp. 203-220.

4. Thompson, D.L. "Thermal Management Innovations in Customized PDC Drill Bit Applications." Applied Thermal Engineering, Vol. 186, 2023, pp. 45-61.

5. Chen, W.F. and Miller, J.S. "Manufacturing Excellence in Custom Drill Tool Production: Quality Assurance Methodologies." Manufacturing Technology International, Vol. 29, No. 4, 2023, pp. 156-174.

6. Anderson, K.R. et al. "Performance Optimization Through Application-Driven PDC Drill Bit Customization." Energy Technology Review, Vol. 48, No. 7, 2023, pp. 89-106.