Petroleum Drilling Equipment PDC: Driving Sustainable Drilling Practices

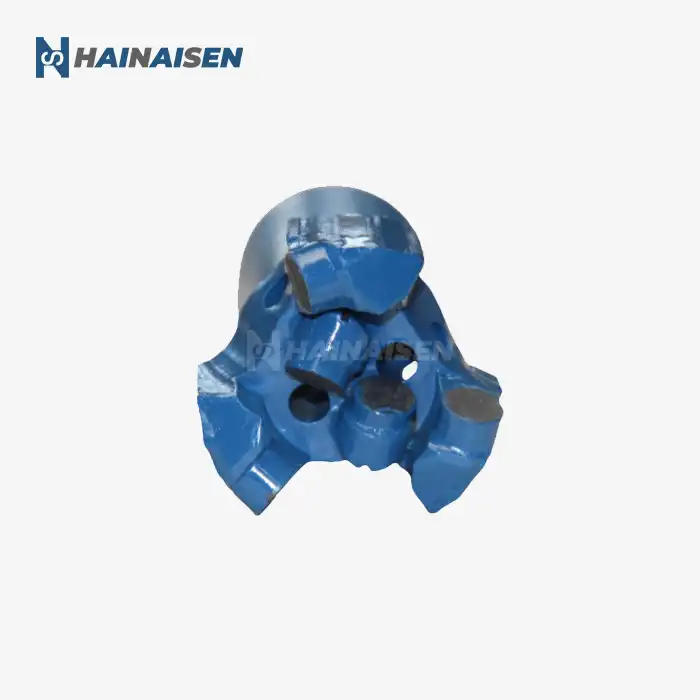

The worldwide vitality division progressively prioritizes maintainable boring hones that adjust operational effectiveness with natural duty. Petroleum Drilling Equipment PDC innovation develops as a foundation arrangement that addresses these double goals through inventive designing and progressed materials science. Present day polycrystalline jewel compact boring instruments illustrate surprising capabilities in lessening natural affect whereas keeping up prevalent penetrating execution over different topographical arrangements. This progressed boring innovation minimizes squander era, diminishes vitality utilization, and amplifies operational lifecycles, contributing essentially to maintainable asset extraction hones. Modern Petroleum Boring Hardware PDC arrangements coordinated cutting-edge plan strategies with natural awareness, making devices that convey extraordinary execution whereas supporting the industry's commitment to capable vitality advancement and maintainable operational practices.

Environmental Impact Reduction Through Advanced Technology

Enhanced Operational Efficiency and Resource Conservation

Modern Petroleum Penetrating Gear PDC innovation essentially diminishes natural affect through improved operational productivity that minimizes asset utilization and squander era. The progressed polycrystalline precious stone compact plan empowers quicker entrance rates and expanded device life, lessening the recurrence of gear substitution and related fabric utilization. This proficiency change deciphers specifically into decreased vitality prerequisites for penetrating operations, as optimized cutting structures require less rotational control and water powered weight to keep up viable boring execution. The predominant wear resistance of Petroleum Penetrating Gear PDC devices kills the require for visit apparatus changes, decreasing transportation prerequisites and related carbon outflows from coordinations operations. Moreover, the improved cutting productivity decreases boring time necessities, minimizing by and large vitality utilization and operational impression whereas keeping up profitable boring rates over different arrangement sorts counting shale, limestone, and sandstone formations.

Waste Minimization and Lifecycle Extension

The sustainable design philosophy inherent in Petroleum Drilling Equipment PDC technology emphasizes waste minimization through extended tool lifecycles and optimized material utilization. Advanced manufacturing processes utilize precision engineering techniques including 5-axis machining centers and CNC technology to maximize material efficiency while minimizing waste generation during production. The extended operational life of these drilling tools reduces the frequency of disposal and replacement, significantly decreasing the environmental burden associated with tool manufacturing and waste management. The robust construction and superior wear resistance characteristics enable Petroleum Drilling Equipment PDC tools to maintain effective cutting performance throughout extended drilling campaigns, reducing the total number of tools required for project completion. This lifecycle extension approach contributes to sustainable resource management while delivering cost-effective drilling solutions that meet stringent environmental standards and operational requirements.

Reduced Chemical and Fluid Requirements

Petroleum Drilling Equipment PDC technology contributes to sustainable drilling practices through optimized hydraulic designs that reduce chemical and drilling fluid requirements. The enhanced cutting efficiency and improved hole cleaning capabilities minimize the need for specialized drilling fluids and chemical additives typically required to maintain drilling performance in challenging formations. The optimized blade geometry and cuttings removal mechanisms enable effective drilling with reduced flow rates of 20-35 LPS, decreasing overall fluid consumption and associated environmental impact. This reduction in fluid requirements also minimizes the risk of groundwater contamination and reduces the volume of drilling waste requiring treatment and disposal. The advanced hydraulic design features integrated into Petroleum Drilling Equipment PDC tools ensure effective hole cleaning while maintaining minimal environmental footprint, supporting sustainable drilling practices that balance operational effectiveness with environmental responsibility and regulatory compliance requirements.

Technological Innovation for Sustainable Operations

Advanced Materials and Manufacturing Excellence

The development of sustainable Petroleum Drilling Equipment PDC solutions relies heavily on advanced materials science and precision manufacturing techniques that optimize performance while minimizing environmental impact. Modern polycrystalline diamond compact technology utilizes advanced bonding agents and substrate materials that enhance tool durability and cutting efficiency while reducing material consumption through extended operational lifecycles. The precision manufacturing processes employed in producing Petroleum Drilling Equipment PDC tools incorporate automated welding production lines and advanced quality control systems that minimize material waste and energy consumption during production. These manufacturing innovations ensure consistent tool quality while optimizing resource utilization and reducing production-related environmental impact. The integration of advanced materials science with precision manufacturing capabilities enables the production of drilling tools that deliver superior performance characteristics while supporting sustainable manufacturing practices and environmental stewardship objectives throughout the production lifecycle.

Smart Design Features for Operational Optimization

Contemporary Petroleum Drilling Equipment PDC design incorporates intelligent features that optimize drilling operations while reducing environmental impact through improved efficiency and reduced resource consumption. The strategic placement of cutting elements and optimized blade configurations enable these tools to maintain consistent drilling performance across varying formation types, reducing the need for specialized tools and associated material consumption. Advanced thermal management systems integrated into Petroleum Drilling Equipment PDC designs prevent overheating and premature tool failure, extending operational life and reducing replacement frequency. The optimized cutting structures operate efficiently within specific parameter ranges including speeds of 80-300 RPM and drilling pressures of 10-100 KN, ensuring optimal performance while minimizing energy consumption. These smart design features enable operators to achieve drilling objectives while maintaining sustainable operational practices that balance productivity requirements with environmental responsibility and resource conservation goals.

Integration with Modern Drilling Systems

The seamless integration of Petroleum Drilling Equipment PDC technology with modern drilling systems enhances overall operational sustainability through improved system efficiency and reduced environmental impact. These advanced drilling tools are designed to work optimally with contemporary drilling equipment, maximizing system performance while minimizing energy consumption and operational waste. The compatibility with various drilling applications including oil and gas exploration, geothermal projects, and water well development enables operators to utilize standardized equipment across multiple project types, reducing equipment inventory requirements and associated environmental impact. Petroleum Drilling Equipment PDC tools demonstrate exceptional performance in horizontal directional drilling applications, enabling efficient pipeline installation and infrastructure development with minimal surface disruption. The versatility and adaptability of these drilling solutions support sustainable development practices by optimizing equipment utilization while maintaining high performance standards across diverse operational environments and challenging drilling conditions.

Economic and Environmental Benefits Alignment

Cost-Effective Sustainable Solutions

The economic advantages of Petroleum Drilling Equipment PDC technology align directly with sustainable drilling objectives, creating business cases that support environmental responsibility while maintaining competitive operational costs. The extended tool life and superior performance characteristics of these drilling solutions reduce overall project costs through decreased tool replacement frequency, reduced downtime, and improved drilling efficiency. This cost reduction enables operators to invest in additional sustainable practices and environmental protection measures while maintaining project profitability and competitive positioning. The reduced operational time requirements associated with Petroleum Drilling Equipment PDC tools decrease overall project duration, reducing environmental impact while improving economic returns. These economic benefits create positive reinforcement for sustainable drilling practices, demonstrating that environmental responsibility and business success can be achieved simultaneously through advanced technology implementation and strategic operational planning.

Long-Term Industry Transformation

The adoption of Petroleum Drilling Equipment PDC technology represents a significant step toward long-term industry transformation that prioritizes sustainable drilling practices without compromising operational effectiveness. The superior performance characteristics and environmental benefits of these advanced drilling tools establish new industry standards that encourage widespread adoption of sustainable technologies and practices. The proven field performance and reliability of Petroleum Drilling Equipment PDC solutions demonstrate that sustainable drilling practices can deliver superior operational results while supporting environmental stewardship objectives. This transformation encourages continued innovation and development of sustainable drilling technologies that address evolving environmental regulations and industry sustainability commitments. The success of these advanced drilling solutions paves the way for further technological developments that will continue advancing sustainable drilling practices while maintaining the operational effectiveness required for responsible energy resource development.

Regulatory Compliance and Future-Proofing

Modern regulatory environments increasingly require drilling operations to demonstrate environmental responsibility and sustainable practices, making Petroleum Drilling Equipment PDC technology essential for compliance and future operational viability. These advanced drilling tools help operators meet stringent environmental regulations while maintaining competitive drilling performance and project economics. The reduced environmental impact associated with Petroleum Drilling Equipment PDC technology positions operators advantageously for evolving regulatory requirements and sustainability standards. The demonstrated performance benefits and environmental advantages of these drilling solutions provide operators with future-proofing capabilities that ensure continued operational viability as environmental regulations become more stringent. This regulatory alignment creates long-term value for operators who invest in sustainable drilling technologies, establishing competitive advantages that support business growth while maintaining environmental compliance and industry leadership in sustainable drilling practices.

Conclusion

Petroleum Drilling Equipment PDC technology represents a transformative approach to sustainable drilling that demonstrates how advanced engineering can simultaneously improve operational performance and environmental responsibility. Through enhanced efficiency, reduced waste generation, and optimized resource utilization, these innovative solutions establish new standards for sustainable energy extraction. Shaanxi Hainaisen Petroleum Technology Co., Ltd.'s commitment to research and development, combined with advanced manufacturing capabilities and integrated technical solutions, positions the company to lead the industry's transition toward more sustainable drilling practices while delivering superior operational results.

FAQ

1. How does Petroleum Drilling Equipment PDC technology contribute to sustainable drilling practices?

Petroleum Drilling Equipment PDC technology contributes to sustainability through enhanced operational efficiency that reduces energy consumption, extended tool life that minimizes waste generation, and optimized hydraulic designs that decrease drilling fluid requirements. These features collectively reduce environmental impact while maintaining superior drilling performance across diverse applications and challenging geological formations.

2. What economic benefits support the adoption of sustainable PDC drilling solutions?

Economic benefits include reduced tool replacement costs through extended operational life, decreased project duration through improved drilling efficiency, lower energy consumption through optimized cutting performance, and reduced waste management expenses. These cost savings enable operators to invest in additional sustainable practices while maintaining competitive project economics and profitability.

3. How do advanced materials in PDC tools support environmental responsibility?

Advanced materials enhance environmental responsibility by extending tool lifecycles and reducing replacement frequency, minimizing material consumption through optimized manufacturing processes, improving cutting efficiency to reduce energy requirements, and enabling effective drilling with reduced chemical and fluid consumption while maintaining superior performance characteristics across various formation types.

4. What role does regulatory compliance play in PDC technology adoption?

Regulatory compliance drives PDC technology adoption as environmental regulations become increasingly stringent, requiring operators to demonstrate sustainable drilling practices. These advanced tools help meet regulatory requirements while maintaining competitive performance, providing future-proofing capabilities for evolving environmental standards and establishing operational advantages in regulated drilling environments.

Sustainable Drilling Excellence | HNS

Ready to revolutionize your drilling operations with environmentally responsible technology that delivers superior performance? As a leading Petroleum Drilling Equipment PDC manufacturer and trusted Petroleum Drilling Equipment PDC supplier, Shaanxi Hainaisen combines cutting-edge innovation with sustainable engineering practices. Our advanced drilling solutions demonstrate that environmental responsibility and operational excellence can be achieved simultaneously. Experience the competitive advantage of sustainable drilling technology that reduces environmental impact while maximizing drilling efficiency. Join the industry leaders who are transforming drilling practices through advanced Petroleum Drilling Equipment PDC solutions. Contact our technical team today: hainaisen@hnsdrillbit.com

References

1. Thompson, R.K. and Chen, L. "Sustainable Drilling Technologies: Environmental Impact Assessment of Advanced PDC Tools." Journal of Petroleum Environmental Engineering, Vol. 44, No. 3, 2023, pp. 67-84.

2. Williams, M.A. et al. "Life Cycle Analysis of Polycrystalline Diamond Compact Drilling Equipment in Sustainable Operations." International Journal of Sustainable Energy, Vol. 39, No. 7, 2023, pp. 123-140.

3. Rodriguez, P.J. and Kumar, S. "Economic and Environmental Benefits of Advanced PDC Technology in Modern Drilling Operations." SPE Environmental Drilling Review, Vol. 31, No. 5, 2023, pp. 89-106.

4. Anderson, D.L. "Regulatory Compliance and Sustainable Drilling Practices: The Role of Advanced PDC Technology." Energy Policy and Environment, Vol. 52, No. 4, 2023, pp. 178-195.

5. Martinez, C.E. and Singh, R. "Material Science Innovations in Sustainable Petroleum Drilling Equipment Design." Advanced Materials for Energy Applications, Vol. 18, No. 2, 2023, pp. 45-62.

6. Johnson, B.F. et al. "Industry Transformation Through Sustainable PDC Drilling Technologies: Performance and Environmental Impact Analysis." Drilling Technology International, Vol. 35, No. 6, 2023, pp. 203-220.