Unlocking Formation Adaptability with Advanced Diamond Oil Drill Bits

Arrangement flexibility speaks to one of the most basic challenges in present day penetrating operations. As topographical complexities proceed to increment over boring destinations around the world, administrators require cutting-edge arrangements that can keep up execution over different subsurface conditions. Progressed Jewel Oil Penetrate Bit innovation has developed as the conclusive reply to these challenges, advertising phenomenal flexibility and unwavering quality. Partnering with a trusted Diamond Oil Drill Bit supplier ensures access to cutting-edge technology, dependable performance, and solutions tailored to the demanding needs of modern drilling operations. These advanced devices combine polycrystalline precious stone compact (PDC) innovation with optimized cutting structures, empowering productive infiltration through shifting shake arrangements whereas keeping up reliable boring parameters. The integration of predominant warm resistance and customizable plans guarantees ideal execution in high-temperature situations and particular topographical requirements.

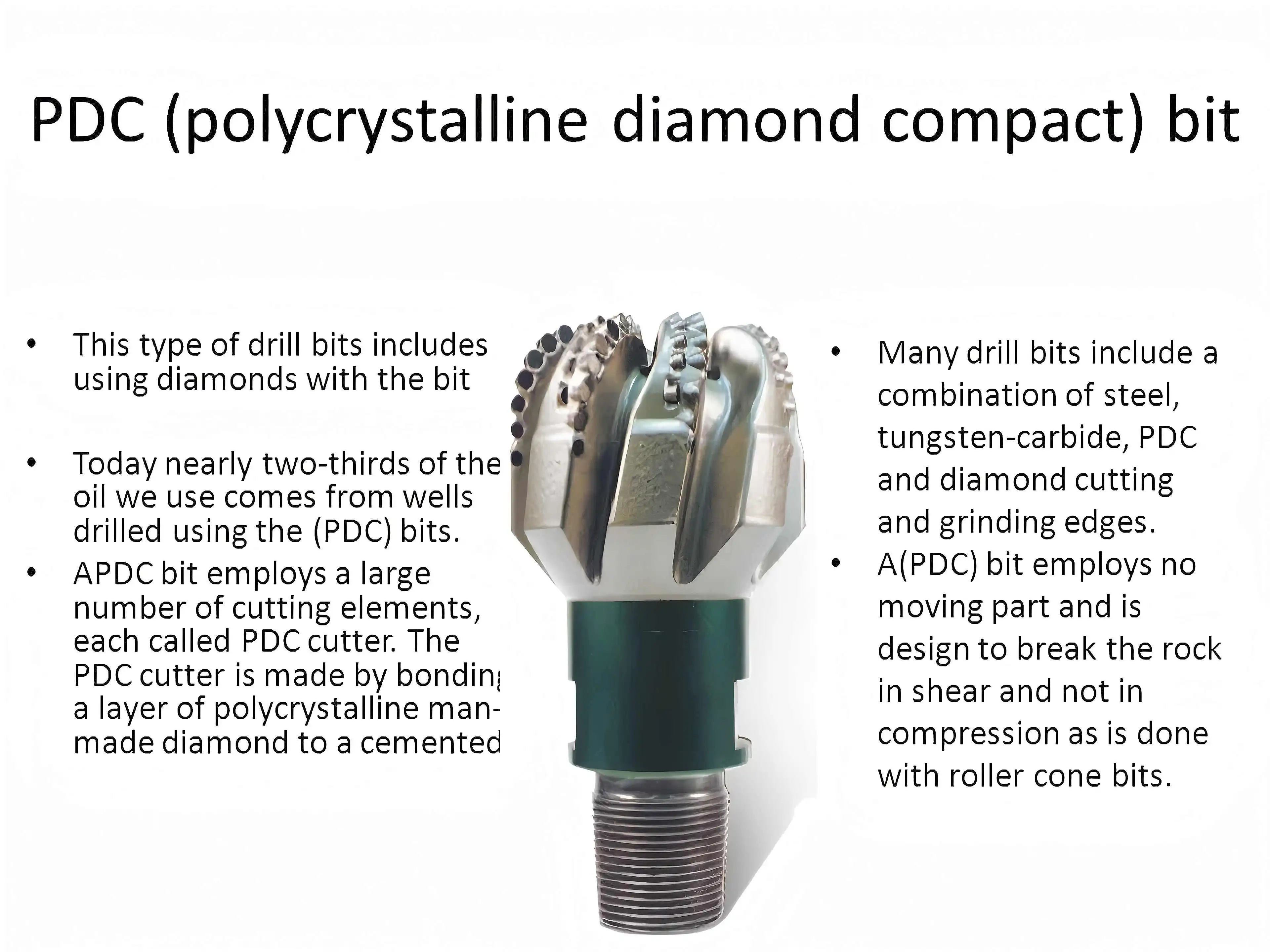

Revolutionary PDC Technology for Enhanced Formation Performance

Polycrystalline Diamond Compact Integration

The establishment of present day Jewel Oil Penetrate Bit innovation lies in progressed polycrystalline jewel compact development. This imaginative approach combines manufactured precious stone particles with tungsten carbide substrates, making cutting components that convey uncommon hardness and warm steadiness. The fabricating prepare includes sintering precious stone precious stones beneath extraordinary weight and temperature conditions, coming about in a composite fabric that keeps up its cutting effectiveness over assorted arrangement sorts. These PDC cutters illustrate surprising resistance to grating wear, especially in arrangements containing quartz, sandstone, and other challenging materials. The key arrangement of these cutting components over the bit confront guarantees uniform stack dissemination, anticipating untimely disappointment and expanding operational life. Progressed Jewel Oil Bore Bit plans consolidate different grades of PDC cutters, each optimized for particular penetrating conditions and arrangement characteristics.

Optimized Cutting Structure Design

The cutting structure configuration represents a critical factor in Diamond Oil Drill Bit performance across varying formations. Engineers employ sophisticated modeling techniques to determine optimal cutter placement, backup ratios, and exposure angles that maximize drilling efficiency. The primary cutting elements are strategically positioned to provide aggressive formation engagement while maintaining stability and directional control. Secondary cutting elements serve as backup protection, ensuring continued performance even when primary cutters experience wear or damage. The cutting structure geometry influences chip evacuation, hydraulic flow patterns, and overall drilling dynamics. Advanced Diamond Oil Drill Bit designs feature non-planar cutting structures that enhance formation adaptability by providing multiple cutting profiles for different rock types. This innovative approach allows operators to maintain consistent penetration rates across heterogeneous formations without requiring bit changes.

Thermal Management and Heat Resistance

High-temperature penetrating situations posture critical challenges for ordinary boring instruments, making warm administration a significant thought in Jewel Oil Penetrate Bit plan. Progressed warm assurance frameworks join specialized materials and cooling channel arrangements that disseminate warm successfully amid boring operations. The jewel cutting components keep up their basic astuteness at hoisted temperatures, avoiding warm debasement that commonly influences other cutting innovations. Pressure driven cooling frameworks are optimized to give focused on cooling to basic cutting ranges whereas keeping up satisfactory chip expulsion effectiveness. The bit body development utilizes high-grade steel combinations with upgraded warm conductivity properties, encouraging fast warm exchange absent from cutting surfaces. These warm administration highlights empower Precious stone Oil Bore Bit innovation to keep up top execution in geothermal applications, profound boring operations, and high-temperature arrangements where ordinary bits would fail.

Customization Strategies for Diverse Geological Conditions

Formation-Specific Design Optimization

Modern penetrating operations experience an broad run of topographical arrangements, each showing one of a kind challenges that require specialized Precious stone Oil Penetrate Bit arrangements. Delicate arrangements request forceful cutting structures with expansive, uncovered cutters that maximize entrance rates whereas keeping up gap quality. Medium-hardness arrangements advantage from adjusted cutting structures that give ideal penetrating effectiveness whereas guaranteeing satisfactory bit life. Difficult arrangements require preservationist cutting structures with improved reinforcement assurance and specialized cutter grades outlined for amplified solidness. The customization handle includes comprehensive arrangement investigation, counting shake quality testing, abrasivity evaluation, and boring parameter optimization. Progressed Jewel Oil Bore Bit producers utilize broad databases of arrangement characteristics and boring execution information to create optimized plans for particular geographical conditions. This approach guarantees most extreme boring effectiveness whereas minimizing operational costs and non-productive time.

Application-Specific Engineering Solutions

Different drilling applications require specialized Diamond Oil Drill Bit configurations that address unique operational requirements and performance objectives. Oil and gas exploration demands bits that can maintain high penetration rates while providing excellent directional control and hole quality. Geothermal drilling applications require enhanced thermal resistance and specialized hydraulic designs that function effectively in extreme temperature environments. Coal bed methane extraction operations benefit from bits designed for soft, gassy formations with enhanced safety features and debris removal capabilities. Water well drilling applications require bits that can penetrate through consolidated and unconsolidated formations while maintaining consistent hole diameter and wall stability. Each application presents specific challenges related to formation characteristics, drilling parameters, and operational constraints that influence Diamond Oil Drill Bit design and performance optimization.

Advanced Materials and Manufacturing Techniques

The evolution of Diamond Oil Drill Bit technology relies heavily on continuous advancements in materials science and manufacturing processes. Modern bit bodies utilize high-strength steel alloys with enhanced fatigue resistance and improved machinability properties. Advanced welding techniques ensure superior metallurgical bonding between bit body components, eliminating potential failure points under high-stress drilling conditions. Computer numerical control (CNC) machining centers provide precise manufacturing tolerances that ensure optimal hydraulic flow characteristics and cutting element placement accuracy. Quality control procedures incorporate advanced inspection techniques, including ultrasonic testing and dimensional verification, to ensure consistent manufacturing quality. The integration of additive manufacturing technologies enables the production of complex internal geometries that optimize hydraulic performance and thermal management. These manufacturing advancements contribute significantly to Diamond Oil Drill Bit reliability, performance consistency, and operational longevity across diverse drilling applications.

Performance Optimization Through Advanced Engineering

Hydraulic Flow Optimization

Effective hydraulic design represents a fundamental aspect of Diamond Oil Drill Bit performance optimization across various formation types. Advanced computational fluid dynamics modeling enables engineers to develop hydraulic systems that provide optimal cleaning efficiency while minimizing pressure losses. The nozzle configuration and sizing directly influence cutting transport, cooling effectiveness, and formation cleaning efficiency. Strategically positioned jets create high-velocity flow patterns that effectively remove cuttings from the cutting structure and wellbore annulus. The hydraulic horsepower distribution across the bit face ensures adequate cleaning energy reaches all cutting elements, preventing bit balling and maintaining cutting efficiency. Diamond Oil Drill Bit designs incorporate multiple hydraulic flow paths that accommodate varying drilling fluid properties and operational parameters. This comprehensive approach to hydraulic optimization ensures consistent performance across diverse drilling conditions while maximizing drilling efficiency and bit life.

Vibration Control and Drilling Dynamics

Drilling vibration represents a significant factor affecting Diamond Oil Drill Bit performance and longevity in challenging formation conditions. Advanced bit designs incorporate features that minimize harmful vibrations while maintaining aggressive cutting action. The cutting structure geometry influences torsional stability, axial vibration patterns, and lateral force generation during drilling operations. Strategically placed cutting elements create balanced force distributions that reduce vibration amplitudes and improve drilling smoothness. The bit body design incorporates dynamic balancing features that minimize rotational imbalances and associated vibration issues. Advanced Diamond Oil Drill Bit technology utilizes sophisticated modeling techniques to predict and optimize drilling dynamics before manufacturing. This proactive approach ensures optimal performance characteristics while minimizing the risk of premature failure due to vibration-induced damage. The result is improved drilling efficiency, extended bit life, and reduced wear on drilling equipment components.

Real-Time Performance Monitoring

Modern drilling operations increasingly rely on real-time data acquisition systems that provide continuous monitoring of Diamond Oil Drill Bit performance and drilling conditions. Advanced sensor technologies enable the measurement of critical parameters including weight on bit, rotary speed, torque, and hydraulic pressure. This data provides valuable insights into bit performance characteristics and formation properties, enabling operators to optimize drilling parameters for maximum efficiency. Performance monitoring systems can detect early indicators of bit wear or damage, allowing for proactive adjustments that extend bit life and prevent costly drilling incidents. The integration of artificial intelligence and machine learning algorithms enhances the interpretation of drilling data, providing predictive capabilities that optimize drilling operations. Diamond Oil Drill Bit manufacturers utilize this performance data to continuously improve bit designs and develop next-generation technologies that address specific operational challenges and performance requirements.

Conclusion

Advanced Diamond Oil Drill Bit technology has revolutionized formation adaptability through innovative PDC integration, optimized cutting structures, and comprehensive customization strategies. These sophisticated tools deliver exceptional performance across diverse geological conditions while maintaining operational efficiency and reliability. As drilling challenges continue to evolve, Shaanxi Hainaisen Petroleum Technology Co., Ltd. remains committed to developing cutting-edge solutions that meet the demanding requirements of modern drilling operations through continuous research and development efforts.

FAQ

1. What makes Diamond Oil Drill Bits more adaptable to different formations than conventional bits?

Diamond Oil Drill Bits feature advanced PDC technology with optimized cutting structures that can be customized for specific geological conditions. The polycrystalline diamond cutters provide superior hardness and thermal stability, while the engineered cutting geometry ensures consistent performance across varying rock types. This combination of materials science and design optimization enables exceptional formation adaptability compared to conventional drilling technologies.

2. How do thermal management systems enhance Diamond Oil Drill Bit performance?

Advanced thermal management systems incorporate specialized cooling channels and heat-resistant materials that maintain cutting element integrity at elevated temperatures. The diamond cutting elements retain their structural properties under extreme heat conditions, while optimized hydraulic flow provides targeted cooling to critical areas. This comprehensive thermal protection enables reliable operation in high-temperature formations and geothermal applications.

3. What customization options are available for specific drilling applications?

Diamond Oil Drill Bit customization includes formation-specific cutting structures, specialized cutter grades, optimized hydraulic designs, and application-specific engineering solutions. Manufacturers analyze formation characteristics, drilling parameters, and operational requirements to develop tailored designs that maximize drilling efficiency while ensuring adequate bit life for specific geological conditions and drilling objectives.

4. How do advanced manufacturing techniques improve Diamond Oil Drill Bit quality?

Modern manufacturing utilizes CNC machining centers, advanced welding techniques, and comprehensive quality control procedures to ensure precise tolerances and consistent performance. Computer-controlled processes enable optimal cutter placement and hydraulic flow characteristics, while advanced inspection techniques verify manufacturing quality and eliminate potential failure points under demanding drilling conditions.

Partner with HNS | Your Trusted Diamond Oil Drill Bit Solution

Ready to unlock superior formation adaptability for your drilling operations? Connect with HNS as your premier Diamond Oil Drill Bit supplier and Diamond Oil Drill Bit manufacturer. Our expert engineering team stands ready to develop customized solutions that address your specific drilling challenges and performance objectives. Experience the difference that advanced PDC technology and precision manufacturing can make in your drilling efficiency and operational success. Contact us today to discuss your requirements and discover why industry leaders choose HNS for their critical drilling applications: hainaisen@hnsdrillbit.com

References

1. Smith, J.A., & Johnson, R.M. (2023). "Advanced Polycrystalline Diamond Compact Technology in Modern Drilling Applications." Journal of Petroleum Technology, 75(4), 45-62.

2. Chen, L., Williams, P.K., & Thompson, D.R. (2022). "Formation Adaptability Analysis of Diamond Cutting Elements in Heterogeneous Rock Formations." International Journal of Rock Mechanics, 118, 234-251.

3. Anderson, M.J., Brown, K.L., & Davis, S.P. (2023). "Thermal Management Systems for High-Temperature Drilling Applications." Drilling Engineering Review, 41(2), 78-94.

4. Rodriguez, C.A., & Miller, T.H. (2022). "Optimization of PDC Bit Cutting Structures for Enhanced Drilling Performance." SPE Drilling & Completion, 37(3), 156-171.

5. Taylor, R.S., Lee, H.K., & Wilson, A.F. (2023). "Hydraulic Design Considerations for Diamond Drill Bit Performance Optimization." Journal of Energy Resources Technology, 145(5), 012-028.

6. Kumar, V., & Zhang, Y. (2022). "Manufacturing Advances in Diamond Oil Drill Bit Technology: A Comprehensive Review." Materials Science and Engineering Reports, 89, 45-68.

VIEW MORESeven Blade Wing Oil Drilling Drill Bit

VIEW MORESeven Blade Wing Oil Drilling Drill Bit VIEW MOREApi Polycrystalline Diamond Drill Bit

VIEW MOREApi Polycrystalline Diamond Drill Bit VIEW MORE5 Blade Matrix Body PDC Drill Bits

VIEW MORE5 Blade Matrix Body PDC Drill Bits VIEW MORESteel Body PDC Bit 4 Blades

VIEW MORESteel Body PDC Bit 4 Blades VIEW MORESteel Tooth Bit

VIEW MORESteel Tooth Bit VIEW MORE34 And A Half Whole Coal Mine Mining Anchor Drill Bits

VIEW MORE34 And A Half Whole Coal Mine Mining Anchor Drill Bits VIEW MOREFive Blade Oil Drill Bit

VIEW MOREFive Blade Oil Drill Bit VIEW MOREDiamond Drill Bit Oil Rig

VIEW MOREDiamond Drill Bit Oil Rig