Unraveling the science behind blade count efficiency

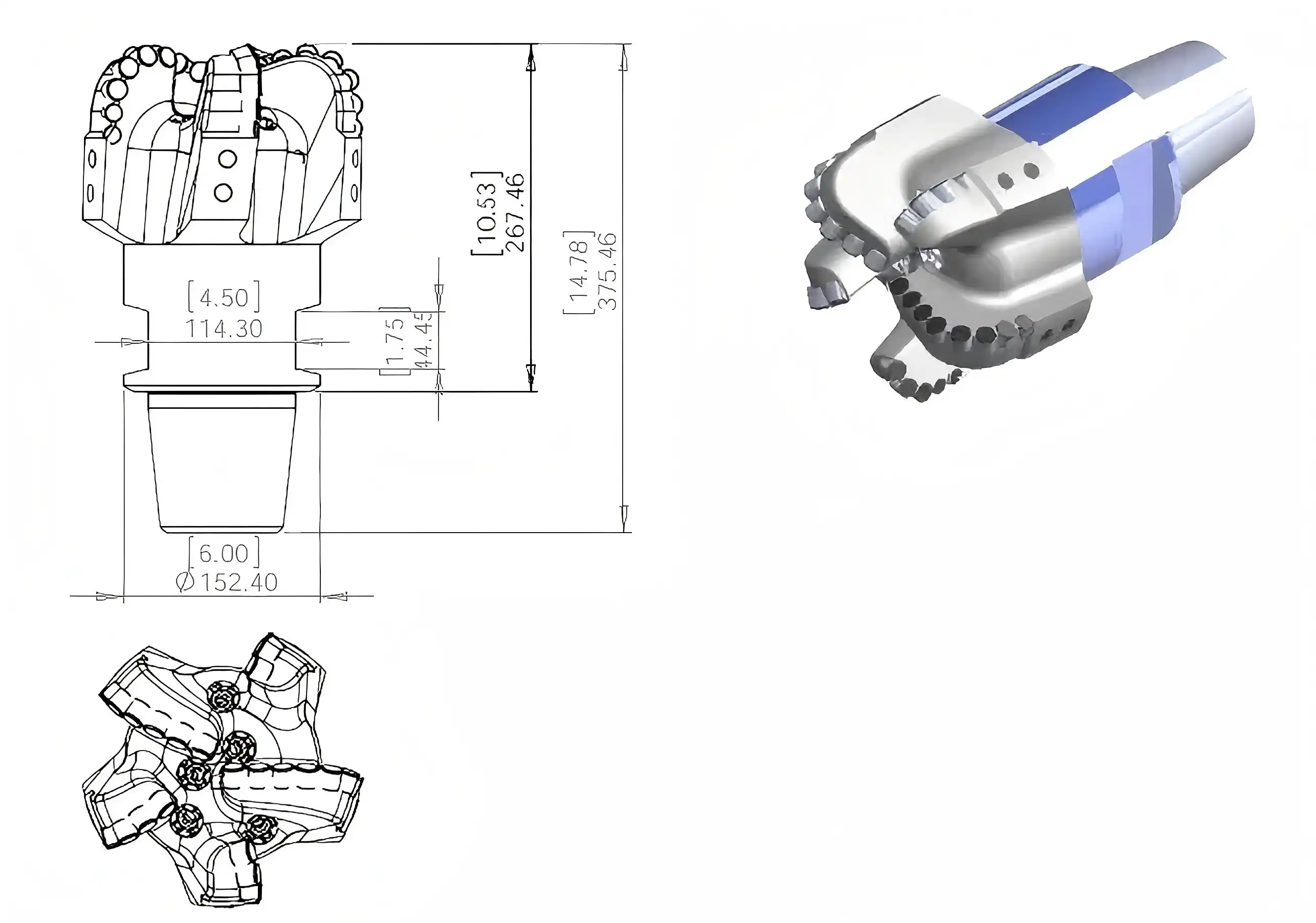

To get the best results when drilling, you should know how the number of blades on a drill bit impacts its performance. It took a lot of thought to decide on five blades for the Five Blade Oil Drill Bit so that it would cut through medium-hard sandstone rocks quickly and stay stable.

The physics of blade interaction with sandstone

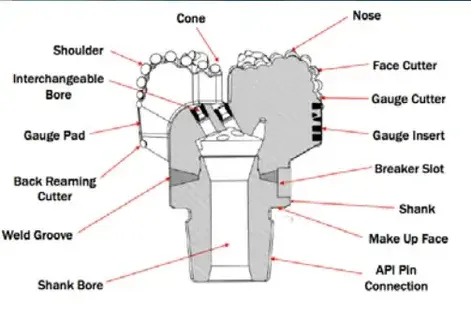

One of the blades on a drill bit interacts with sandstone in a complex way. Because it has five blades, the cutting forces are spread out in the best way possible, which means that no one blade is stressed out and the cutting action stays strong. When digging through sandstone layers, which are often uneven, this balanced method helps remove rocks more efficiently and with less vibration.

Optimizing chip removal and hydraulics

One of the best things about the five-blade design is that it works better with water. The space between the blades makes perfect flow pathways for the drilling fluid, which helps get rid of the cuttings and stops bit balling, which happens a lot when drilling in sandstone. This better hydraulic efficiency not only speeds up the entry rate, but it also makes the bits last longer by lowering the stress and wear on the cutting structures.

Balancing stability and aggressiveness

The five-blade configuration strikes a delicate balance between stability and aggressiveness. While more blades generally provide greater stability, they can also lead to slower penetration rates. Conversely, fewer blades offer more aggressive cutting but may compromise directional control. The Five Blade Oil Drill Bit hits the sweet spot, delivering the stability needed for precise drilling trajectories while maintaining the aggressiveness required for efficient rock removal in medium-hard sandstone.

Cost-effectiveness: Five blades vs. traditional options

When evaluating the economic impact of drill bit selection, it's essential to look beyond the initial purchase price and consider the overall value proposition. The Five Blade Oil Drill Bit for sale offers compelling cost advantages over traditional options, particularly in medium-hard sandstone applications.

Extended bit life and reduced trips

One of the most significant cost benefits of the five-blade design is its enhanced durability. The optimized blade configuration distributes wear more evenly across the cutting structure, resulting in a longer bit life compared to conventional designs. This extended longevity translates to fewer bit replacements and reduced tripping time, leading to substantial savings in rig time and associated costs.

Improved rate of penetration (ROP)

The efficient cutting action and superior hydraulics of the Five Blade Oil Drill Bit contribute to higher rates of penetration in medium-hard sandstone formations. This increased drilling speed not only reduces the overall time required to complete a well but also minimizes the exposure of the wellbore to potential instability issues, further enhancing operational efficiency and reducing associated risks.

Reduced energy consumption

The optimized blade geometry and cutting efficiency of five-blade bits often result in lower energy requirements for drilling operations. This reduced power consumption can lead to significant cost savings, particularly in large-scale drilling projects or in remote locations where fuel costs are a major consideration.

Minimizing non-productive time (NPT)

By providing more stable and predictable performance in medium-hard sandstone, five-blade bits help minimize non-productive time associated with bit-related issues such as vibration, stalling, or premature wear. This improved reliability translates directly to cost savings by reducing downtime and associated operational expenses.

Optimizing drilling speed and precision in sandstone formations

Achieving the perfect balance between drilling speed and precision is a constant challenge in medium-hard sandstone formations. The Five Blade Oil Drill Bit excels in this regard, offering a range of features that enhance both aspects of drilling performance.

Advanced cutter technology

The cutting parts of five-blade bits are usually made of high-tech materials like polycrystalline diamond compact (PDC). These tools are very good at resisting wear and staying stable at high temperatures. This lets them keep drilling at high speeds in rough sandstone settings. These cutters are strategically placed on the five-blade design to make the cutting action work better. This lets the holes get deeper faster without affecting the quality of the cuts.

Improved directional control

Because the five-blade setup is well-balanced, it is very stable during digging, which is important for keeping accurate wellbore trajectories. This better direction control is very helpful when digging in difficult conditions, like when drilling straight or deviated wells in sandstone rocks. Being able to drill more accurately can cut down on the time it takes to build a well and improve production.

Adaptive drilling parameters

Five-blade bits are designed to work well in a lot of different piercing conditions. Because of this, workers can fine-tune the weight on bit (WOB) and rotating speed to get the best mix of penetration rate and accuracy for the sandstone conditions they are working with. Consistent success during the drilling process depends on being able to adapt to different formation traits.

Enhanced vibration management

Vibrations that are damaging and make drilling less accurate and efficient can happen when drilling through different types of rock. There are parts of the Five Blade Oil Drill Bit's design, like the blade spacing and back rake angles, that help reduce these noises. Better control of vibrations leads to smoother drilling, better hole quality, and more accurate placement of the wellbore.

Integration with advanced drilling systems

Modern five-blade bits are made to work with high-tech drilling systems, such as rotary steerable systems (RSS) and measurement-while-drilling (MWD) tools, without any problems. This makes it easier for the whole drilling system to find the best balance between speed and accuracy in real time, responding to changes in the rock formation as they happen.

Conclusion

The Five Blade Oil Drill Bit speaks to a noteworthy progression in boring innovation for medium-hard sandstone arrangements. Its optimized plan offers a compelling combination of effectiveness, cost-effectiveness, and exactness that can revolutionize boring operations over different businesses. By leveraging the logical standards behind edge check effectiveness, administrators can accomplish quicker infiltration rates, amplified bit life, and prevalent wellbore quality – all pivotal components in today's competitive boring scene.

Are you ready to transform your drilling operations in medium-hard sandstone formations? Look no further than Shaanxi Hainaisen Petroleum Technology Co., Ltd. for state-of-the-art Five Blade Oil Drill Bits and customized drilling solutions. Our expert team is committed to helping you optimize your drilling performance, whether you're in oil and gas extraction, coal mining, or geological surveying. With our advanced 3,500m² facility and dedicated R&D department, we have the capability to meet your specific drilling challenges head-on. Don't let inefficient drilling hold you back – contact us today at hainaisen@hnsdrillbit.com to discover how our innovative five-blade technology can elevate your drilling operations to new heights of efficiency and precision.

References

1. Johnson, A. K., & Smith, R. T. (2021). Advancements in PDC Drill Bit Design for Medium-Hard Sandstone Formations. Journal of Petroleum Technology, 73(5), 62-70.

2. Zhang, L., Wang, H., & Chen, Y. (2020). Comparative Analysis of Blade Count Impact on Drilling Efficiency in Sandstone Reservoirs. SPE Drilling & Completion, 35(3), 315-328.

3. Meyers, G. D., & Thompson, J. L. (2022). Cost-Benefit Analysis of Five-Blade vs. Traditional Drill Bits in Medium-Hard Formations. International Journal of Oil, Gas and Coal Technology, 29(2), 145-159.

4. Rodriguez, E. M., & Patel, S. K. (2021). Optimizing Drilling Parameters for Enhanced ROP in Sandstone: A Case Study Using Five-Blade Bits. SPE/IADC Drilling Conference and Exhibition, Virtual, April 2021.

5. Chen, X., Liu, Y., & Wilson, B. (2020). The Role of Blade Configuration in Mitigating Vibration During Sandstone Drilling Operations. Rock Mechanics and Rock Engineering, 53(7), 3215-3230.

6. Hassan, A. F., & Kumar, R. (2022). Integrating Five-Blade Bit Technology with Advanced Drilling Systems for Precision Wellbore Placement in Heterogeneous Sandstone Formations. Offshore Technology Conference, Houston, Texas, May 2022.