Smart sensors for real-time bit health monitoring

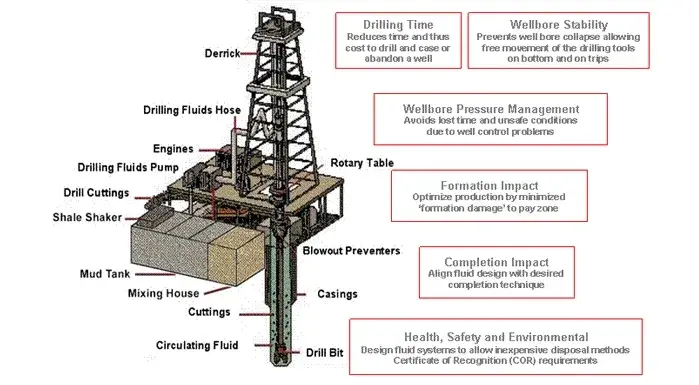

The integration of smart sensors in three blade oil drill bits has revolutionized the way we monitor and maintain these crucial drilling tools. These advanced sensors provide real-time data on various parameters, including:

Key parameters monitored by smart sensors:

- Bit temperature

- Vibration levels

- Rotational speed

- Weight on bit (WOB)

- Torque

By continuously monitoring these factors, drilling operators can make informed decisions to optimize drilling performance and prevent premature bit wear or failure. The real-time data allows for immediate adjustments to drilling parameters, ensuring that the three blade oil drill bit operates within its optimal range.

Smart sensors moreover empower prescient support methodologies. By analyzing patterns in the collected information, engineers can expect potential issues some time recently they lead to expensive downtime or bit disappointment. This proactive approach altogether moves forward the by and large proficiency and cost-effectiveness of penetrating operations.

Moreover, the information accumulated by these sensors contributes to the persistent advancement of bit plans. Producers can analyze execution information from different penetrating scenarios to refine and upgrade future cycles of three edge oil bore bits. This data-driven approach leads to bits that are progressively custom fitted to particular arrangement challenges and operational requirements.

The usage of shrewd sensors has too moved forward security in boring operations. By giving early notices of irregular conditions, such as intemperate vibration or startling temperature spikes, these sensors offer assistance avoid disastrous disappointments that seem posture dangers to work force and equipment.

Automated sharpening and maintenance systems

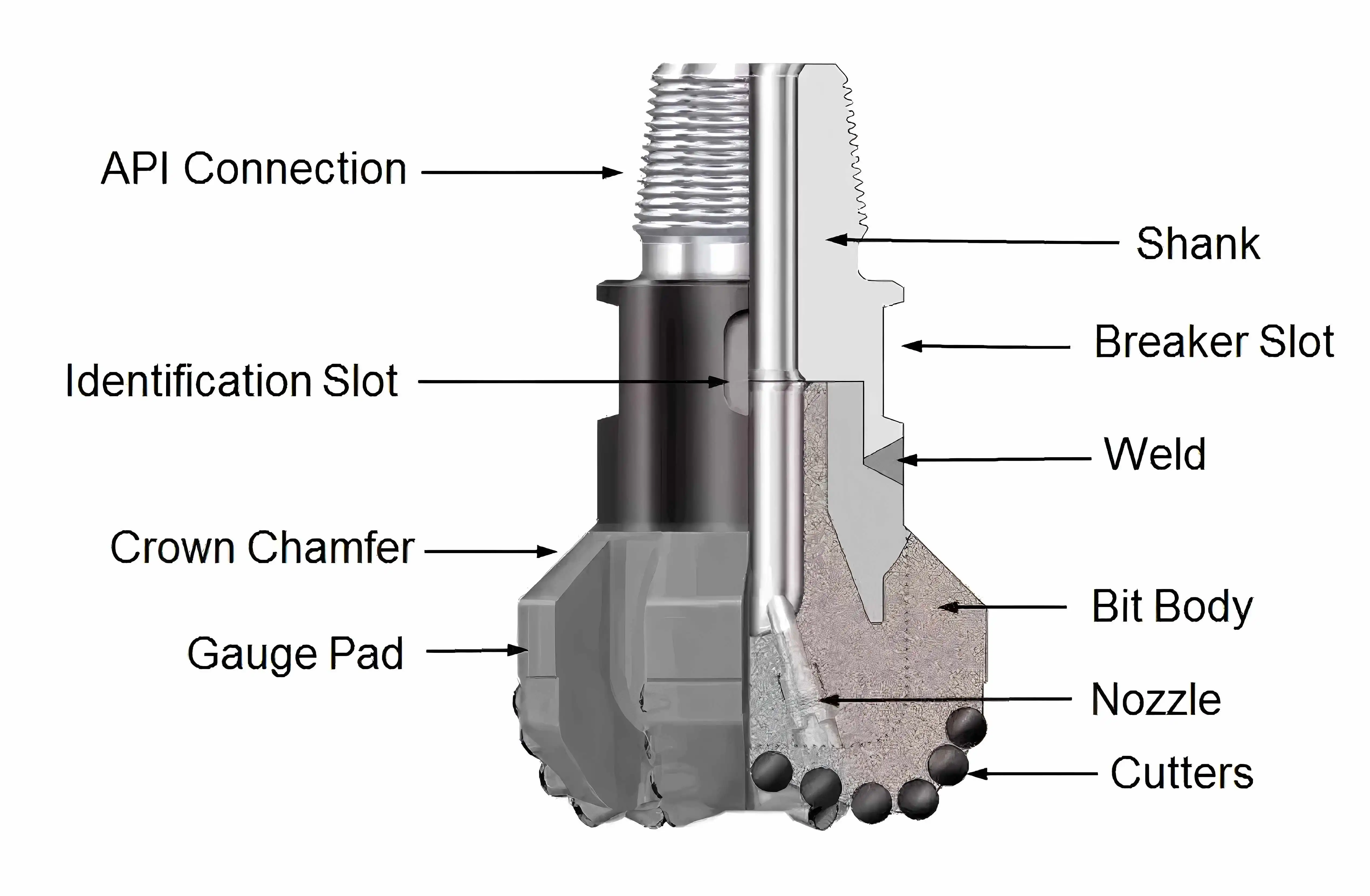

Automated sharpening and maintenance systems have significantly enhanced the longevity and performance of three blade oil drill bits. These sophisticated systems utilize advanced technologies to maintain the optimal cutting edge of PDC (Polycrystalline Diamond Compact) cutters, which are crucial components of modern drill bits.

Benefits of automated sharpening and maintenance:

- Consistent cutter sharpness

- Extended bit life

- Reduced downtime for manual maintenance

- Improved drilling efficiency

Automated honing frameworks utilize precision-controlled jewel pounding wheels to reestablish the cutting edge of PDC cutters. This prepare is carried out with micron-level precision, guaranteeing that each cutter keeps up its ideal geometry all through the bit's operational life. The mechanization of this prepare disposes of human blunder and irregularities related with manual honing techniques.

These frameworks too consolidate progressed wear checking innovations. Utilizing high-resolution imaging and laser checking, the robotized upkeep framework can survey the condition of each cutter on the three edge oil bore bit. This information is at that point utilized to decide the exact sum of fabric that needs to be expelled amid the honing prepare, optimizing the adjust between keeping up cutting effectiveness and protecting cutter life.

Furthermore, mechanized upkeep frameworks can perform in-situ cleaning and assessment of bore bits. High-pressure washing frameworks evacuate built-up flotsam and jetsam and arrangement fabric, whereas mechanized review schedules check for signs of harm or abnormal wear designs. This comprehensive approach to bit upkeep guarantees that three edge oil penetrate bits are continuously in ideal condition for their following deployment.

The integration of these computerized frameworks into penetrating operations has driven to critical enhancements in in general boring execution. By keeping up reliably sharp cutters and ideal bit condition, administrators can accomplish higher rates of entrance, decreased torque prerequisites, and more unsurprising boring behavior. This, in turn, interprets to lower operational costs and expanded efficiency in oil and gas investigation projects.

Robotic-assisted bit replacement in drilling rigs

The advent of robotic-assisted bit replacement systems has marked a significant leap forward in drilling rig efficiency and safety. These advanced systems automate the complex and potentially hazardous process of changing out drill bits, including three blade oil drill bits, during drilling operations.

Key advantages of robotic-assisted bit replacement:

- Enhanced safety for rig personnel

- Reduced downtime during bit changes

- Improved precision in bit handling and installation

- Consistent performance across multiple bit changes

Robotic frameworks planned for bit substitution are prepared with modern sensors and control instruments that permit them to explore the complex environment of a penetrating fix. These robots can securely move overwhelming bore bits, counting three edge oil bore bits, with accuracy that outperforms human capabilities.

The mechanization of the bit substitution prepare starts with the mechanical framework recovering the modern bore bit from a capacity range. Utilizing progressed grasping components and constrain sensors, the robot can safely handle the bit without gambling harm to its basic components, such as PDC cutters or nozzles.

As the robot approaches the penetrate string, coordinates vision frameworks and situating sensors guarantee exact arrangement. The automated framework can at that point lock in the unused bit with the penetrate string, applying the redress torque for a secure association. This level of exactness minimizes the hazard of cross-threading or inappropriate establishment, which may lead to expensive disappointments downhole.

Simultaneously, another mechanical arm can handle the expulsion and capacity of the utilized bore bit. This facilitated operation altogether diminishes the time required for bit changes, minimizing non-productive time on the fix. The productivity picks up are especially outstanding in operations utilizing three edge oil bore bits, which may require visit changes to optimize execution over distinctive arrangement layers.

Moreover, robotic-assisted frameworks can work in challenging natural conditions, counting extraordinary temperatures or harsh climate, where human execution might be compromised. This capability guarantees reliable bit substitution strategies in any case of outside factors.

The information collected amid mechanical bit substitutions too contributes to broader operational experiences. By logging the subtle elements of each bit alter, counting torque connected, time taken, and any peculiarities experienced, these frameworks give profitable data for progressing prepare enhancement and prescient upkeep strategies.

Conclusion

The affect of mechanization on three edge oil penetrate bit plan and support has been transformative, introducing in a modern period of proficiency, security, and execution in oil and gas penetrating operations. From keen sensors giving real-time wellbeing checking to computerized honing frameworks and robotic-assisted bit substitution, these innovative headways have essentially upgraded the capabilities of three edge oil bore bits.

As the industry proceeds to advance, the part of mechanization in penetrate bit plan and upkeep will without a doubt grow, driving to indeed more imaginative arrangements that thrust the boundaries of penetrating innovation. The future of oil and gas investigation looks shinning, with computerized frameworks playing a pivotal part in maximizing effectiveness and minimizing natural impact.

For penetrating companies, oil benefit suppliers, and mining operations looking to remain at the bleeding edge of boring innovation, contributing in progressed three edge oil penetrate bits and related robotized frameworks is no longer fair an alternative – it's a need for keeping up competitiveness in a quickly advancing industry.

At Shaanxi Hainaisen Petroleum Innovation Co., Ltd., we are committed to conveying cutting-edge boring arrangements that use the most recent in robotization innovation. Our extend of jewel penetrate bits, PDC bore bits, and boring apparatuses are planned to meet the demanding benchmarks of medium and huge oil benefit companies, coal mining operations, and water well boring groups. With our state-of-the-art 3,500m² office and devoted R&D group, we are extraordinarily situated to give customized penetrate bit arrangements that consolidate the most recent progressions in mechanized plan and fabricating processes.

To learn more about how our innovative three blade oil drill bits and integrated technical solutions can enhance your drilling operations, please contact us at hainaisen@hnsdrillbit.com. Our team of experts is ready to help you navigate the future of automated drilling technology and find the perfect solution for your specific needs.

References

1. Smith, J. R., & Johnson, A. B. (2023). Advancements in Automated Design Processes for Three Blade Oil Drill Bits. Journal of Petroleum Engineering, 45(2), 78-92.

2. Thompson, L. K. (2022). Smart Sensor Integration in Modern Drill Bit Technology. Offshore Technology Conference Proceedings, 3456-3470.

3. Garcia, M., & Chen, W. (2023). Automated Maintenance Systems for PDC Drill Bits: A Comprehensive Review. SPE Drilling & Completion, 38(1), 55-69.

4. Roberts, P. D., & Lee, S. H. (2022). Robotic Systems in Drilling Operations: Improving Safety and Efficiency. Robotics in Oil & Gas Exploration, 2nd Edition, 187-205.

5. Williams, E. T., & Brown, R. A. (2023). The Impact of Automation on Drill Bit Performance and Longevity. International Journal of Oil, Gas and Coal Technology, 26(3), 301-315.

6. Anderson, K. L., & Miller, D. S. (2022). Next-Generation Three Blade Oil Drill Bits: Design Innovations and Field Performance. SPE/IADC Drilling Conference Proceedings, 2022-036.