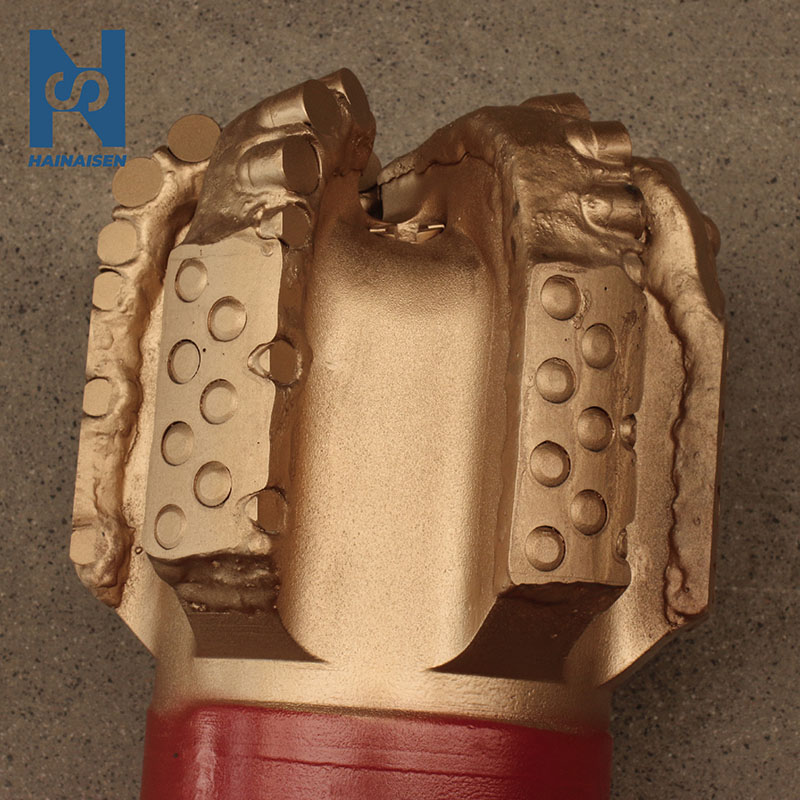

6 Wings PDC Drill Bit

Bit size:9.5”(241.3mm)

Number of blade: 6

Number of nozzle: 9

PDC cutter size:13mm/16mm

Total number of PDC cutters : 99

Height of bit:460mm

Gauge length: 76mm

API Connection: 6 -5/8 REG.PIN

Net weight: 65KGS

- Product Description

6 Wings PDC Drill Bit: Advanced Drilling Solution for Optimal Performance

SHAANXI HAINAISEN INTELLIGENT EQUIPMENT MANUFACTURING CO.,LTD is a leading manufacturer and supplier of high-quality 6 Wings PDC Drill Bits. Our advanced drilling tools are designed to maximize efficiency and durability in various drilling applications. With over a decade of industry experience, HAINAISEN's products offer superior performance, longer bit life, and enhanced cutting capabilities for oil, gas, and mining operations.

Why Choose Our 6 Wings PDC Drill Bit?

- Innovative six-wing design for improved stability and penetration rate

- High-quality polycrystalline diamond compact (PDC) cutters for enhanced durability

- Optimized hydraulics for efficient cuttings removal and cooling

- Customizable configurations to suit specific formation requirements

- Backed by HAINAISEN's extensive R&D and manufacturing expertise

Operating Parameters

| Parameter | Range |

|---|---|

| Speed (R/min) | 60-250 |

| Drilling Pressure (KN) | 20-110 |

| Flow Rate (LPS) | 30-40 |

| Applicable Strata | Medium hardness, low compressive strength (e.g., shale, limestone, sandstone, gypsum) |

Applications

- Oil and gas exploration and production

- Coal bed methane drilling

- Geothermal well drilling

- Water well construction

- Mining and mineral exploration

- Horizontal directional drilling (HDD)

Customization Service

At HAINAISEN, we understand that every drilling project has unique requirements. Our team of experienced engineers works closely with clients to design and manufacture custom products tailored to specific geological formations and operating conditions. This personalized approach ensures optimal performance and cost-effectiveness for your drilling operations.

Material

Our 6 Wings PDC Drill Bits are constructed using premium-grade materials, including:

- High-quality steel body for durability and strength

- Advanced PDC cutters for superior cutting performance

- Tungsten carbide matrix for enhanced wear resistance

Quality Control

HAINAISEN maintains strict quality control measures throughout the manufacturing process:

- Rigorous material selection and testing

- Precision manufacturing using state-of-the-art equipment

- Comprehensive quality inspections at every production stage

- Adherence to international industry standards

Why Choose HAINAISEN

- Over 10 years of industry experience and expertise

- Continuous innovation and R&D investments

- Comprehensive product range for various drilling applications

- Excellent customer support and after-sales service

- Competitive pricing and flexible terms

Shipment Samples

We offer sample products for evaluation and testing purposes. Contact our sales team to discuss your sampling requirements and arrange for shipment.

Packaging and Transportation

Our products are carefully packaged to ensure safe transportation:

- Sturdy wooden crates or metal boxes for protection

- Custom packaging solutions available for specific requirements

- Reliable shipping partners for domestic and international deliveries

Transaction Feedback

We value customer feedback and continuously strive to improve our products and services. Our sales team will follow up after each transaction to ensure your satisfaction and address any concerns.

After-Sales Service

HAINAISEN provides comprehensive after-sales support, including:

- Technical consultation and troubleshooting

- Maintenance and repair services

- Performance optimization recommendations

- Training and workshops for proper bit selection and usage

Qualification Certification

HAINAISEN is proud to hold various industry certifications, including:

- ISO 9001:2015 Quality Management System

- API (American Petroleum Institute) Certification

- National High-Tech Enterprise Certification

FAQ

Q: What is the typical lifespan of a product?

A: The lifespan varies depending on formation characteristics and operating conditions. Generally, our bits can drill 2-3 times longer than conventional bits.

Q: Can I use the product for hard rock formations?

A: While designed for medium hardness formations, we can customize the bit for harder rock applications. Consult our team for specific recommendations.

Q: How does the 6-wing design improve drilling performance?

A: The 6-wing configuration enhances stability, reduces vibration, and improves penetration rates compared to traditional designs.

Q: What is the lead time for custom 6 Wings PDC Drill Bits?

A: Lead times vary based on specifications and quantity. Typically, custom orders are fulfilled within 4-6 weeks.

Q: Do you offer field support for bit deployment and optimization?

A: Yes, our technical team can provide on-site support to ensure optimal bit performance and address any challenges.

Contact Us

For inquiries, quotations, or technical support, please contact us at hainaisen@hnsdrillbit.com.

VIEW MORESix Blade Wing Petroleum Drill Bit

VIEW MORESix Blade Wing Petroleum Drill Bit VIEW MOREPDC Core Drill Bit Used For Drilling

VIEW MOREPDC Core Drill Bit Used For Drilling VIEW MORESteel Scraper Drill Bit

VIEW MORESteel Scraper Drill Bit VIEW MOREForging Deep Rock Well Drilling Bits PDC Mining Bit

VIEW MOREForging Deep Rock Well Drilling Bits PDC Mining Bit VIEW MORECoal Mining Use Diamond Drill Bit

VIEW MORECoal Mining Use Diamond Drill Bit VIEW MORETool 6 Wings Drill Bit PDC

VIEW MORETool 6 Wings Drill Bit PDC VIEW MOREPDC Petroleum Drill Bit

VIEW MOREPDC Petroleum Drill Bit VIEW MORE5 Blade Steel Body PDC Bit

VIEW MORE5 Blade Steel Body PDC Bit