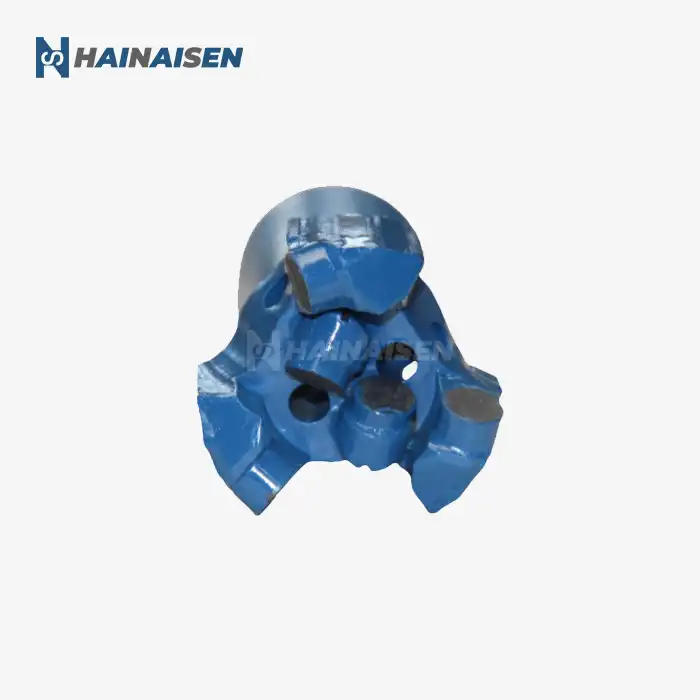

Key Signs of PDC Bit Blade Wear

Recognizing the signs of wear on PDC bit blades is essential for maintaining drilling efficiency and preventing unexpected failures. Here are some critical indicators to watch for:

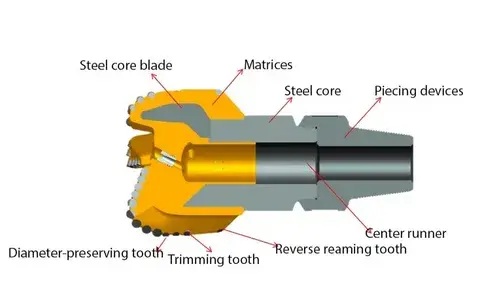

Cutter Wear

One of the most apparent signs of wear on Steel Body PDC Bit 4 Blades is cutter degradation. As the bit drills through various formations, the polycrystalline diamond compact (PDC) cutters experience gradual wear. Look for:

- Flattening of the cutter's leading edge

- Chipping or breakage of cutter edges

- Uneven wear patterns across cutters

These issues can significantly impact the bit's cutting efficiency and should be addressed promptly.

Blade Erosion

The steel body blades themselves are subject to wear, particularly in abrasive formations. Signs of blade erosion include:

- Thinning of blade profiles

- Rounding of blade edges

- Visible grooves or channels on blade surfaces

Excessive blade erosion can compromise the bit's structural integrity and affect its directional stability.

Nozzle and Jet Wear

The hydraulic components of the bit play a crucial role in cuttings removal and cooling. Inspect for:

- Enlargement of nozzle openings

- Erosion around nozzle seats

- Changes in fluid flow patterns

Worn nozzles can lead to inefficient hole cleaning and reduced bit cooling, accelerating overall wear, especially in Steel Body PDC Bit 4 Blades.

Gauge Pad Deterioration

The gauge pads maintain borehole diameter and contribute to directional control. Look out for:

- Excessive wear on gauge pad surfaces

- Rounding of gauge pad edges

- Loss of gauge protection features

Compromised gauge pads can result in undersized holes and directional drilling challenges.

How Wear Affects 4-Blade PDC Performance?

The wear on Steel Body PDC Bit 4 Blades can significantly impact drilling performance in various ways:

Reduced Rate of Penetration (ROP)

As cutters wear down, their ability to efficiently shear formation material diminishes. This leads to:

- Slower drilling progress

- Increased energy consumption

- Extended time on bottom, potentially increasing overall project costs

Decreased Directional Control

Wear on gauge pads and blades can affect the bit's directional characteristics:

- Difficulty maintaining desired trajectory

- Increased risk of wellbore deviation

- Challenges in achieving target zones accurately

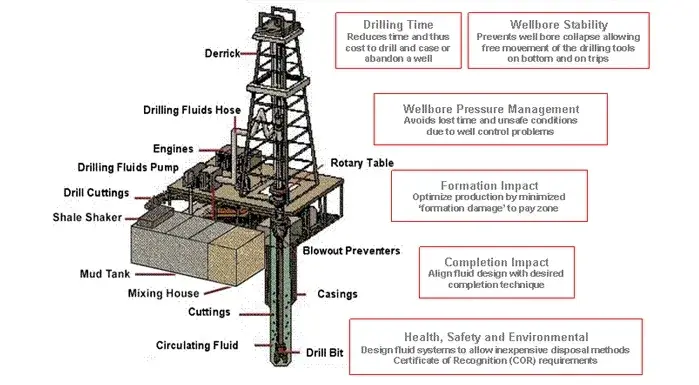

Compromised Hydraulic Efficiency

Worn nozzles and eroded blade surfaces can disrupt optimal fluid flow, especially in Steel Body PDC Bit 4 Blades.

- Inadequate hole cleaning leading to bit balling

- Reduced cooling of cutters, accelerating wear

- Increased risk of downhole motor stalls

Vibration and Instability

Uneven wear across the bit can create imbalances:

- Increased bit whirl and vibration

- Potential damage to downhole tools and bottomhole assembly

- Reduced overall drilling efficiency and potentially shortened bit life

Extending PDC Bit Life: Wear Management Tips

Implementing effective wear management strategies can significantly extend the life of your Steel Body PDC Bit 4 Blades and optimize drilling performance:

Optimize Drilling Parameters

Adjusting operational parameters can minimize premature wear:

- Fine-tune weight on bit (WOB) and rotary speed (RPM) for formation conditions

- Monitor and adjust hydraulics to ensure proper hole cleaning

- Use real-time drilling data to make informed parameter adjustments

Regular Bit Inspections

Implementing a routine inspection schedule helps catch wear issues early:

- Conduct thorough bit evaluations after each run

- Use high-resolution imaging tools for detailed wear analysis

- Document wear patterns to inform future bit selection and operating practices

Strategic Bit Selection

Choosing the right bit for the job is crucial:

- Match bit design to anticipated formation characteristics

- Consider using specialized bits for challenging intervals

- Consult with bit manufacturers for customized solutions

Advanced Cutter Technology

Leveraging cutting-edge PDC cutter technology can enhance wear resistance:

- Utilize premium-grade PDC cutters with enhanced thermal stability

- Consider bits with strategically placed backup cutters

- Explore innovative cutter geometries designed for specific applications

Proper Bit Preservation

Caring for bits between runs can prevent unnecessary wear:

- Clean and inspect bits thoroughly after each use

- Store bits properly to prevent damage to cutting structures

- Apply protective coatings to vulnerable areas when appropriate

By implementing these wear management strategies, drilling teams can significantly extend the life of their Steel Body PDC Bit 4 Blades, improve overall drilling efficiency, and reduce operational costs.

Conclusion

To optimize drilling performance and bit life, it is vital to understand and manage wear indications for Steel Body PDC Bit 4 Blades for sale. Operators may make educated judgments on bit replacement and parameter changes by regularly monitoring cutter wear, blade erosion, hydraulic component degradation, and gauge pad deterioration. Bit life and drilling efficiency may be greatly improved with the use of wear management measures include adjusting drilling settings, performing frequent inspections, and making use of sophisticated cutting technology.

Shaanxi Hainaisen Petroleum Technology Co., Ltd. provides cutting-edge solutions for drilling professionals in need of high-quality Steel Body PDC Bit 4 Blades and experienced advice on cutting-edge wear management. To help you get the most out of your drilling operations, we provide state-of-the-art equipment and individualized technical assistance based on our vast knowledge in drill bit design and production. Improving drilling performance while decreasing operational expenses is possible with our cutting-edge Steel Body PDC Bit 4 Blades. Get in touch with our team of specialists now to learn more. Improve your drilling efficiency with our aid!

FAQ

1. What is the average lifespan of a Steel Body PDC Bit 4 Blades?

The lifespan of a Steel Body PDC Bit 4 Blades can vary significantly depending on factors such as formation characteristics, drilling parameters, and operating conditions. Generally, these bits can last anywhere from 50 to 300 hours of drilling time. However, with proper wear management and optimal operating conditions, some bits have been known to achieve even longer lifespans.

2. How often should I inspect my Steel Body PDC Bit 4 Blades for wear?

It's recommended to conduct a thorough inspection of your Steel Body PDC Bit 4 Blades after each run. Additionally, periodic checks during extended drilling operations can help identify early signs of wear. For critical or challenging drilling projects, more frequent inspections may be necessary to ensure optimal performance and prevent unexpected failures.

3. Can worn Steel Body PDC Bit 4 Blades be repaired or refurbished?

In some cases, Steel Body PDC Bit 4 Blades with moderate wear can be refurbished. This typically involves replacing worn cutters, repairing damaged blades, and restoring hydraulic components. However, the feasibility and cost-effectiveness of refurbishment depend on the extent of wear and the bit's overall condition. It's best to consult with the manufacturer or a specialized bit service company to determine if refurbishment is a viable option for your specific case.

4. How do different formation types affect wear patterns on Steel Body PDC Bit 4 Blades?

Different formation types can produce distinct wear patterns on Steel Body PDC Bit 4 Blades. Soft formations may lead to rapid cutter wear due to high penetration rates, while abrasive formations can cause accelerated blade erosion. Hard, fractured formations might result in impact damage to cutters and blades. Understanding these formation-specific wear patterns can help in selecting the appropriate bit design and implementing effective wear management strategies for each drilling environment.

Steel Body PDC Bit 4 Blades Manufacturer | HNS

Looking for a high-quality, custom-fitted Steel Body PDC Bit 4 Blades? The reliable Shaanxi Hainaisen Petroleum Technology Co., Ltd. is here to assist you with all of your cutting-edge drilling needs. Our innovative products are made with the utmost care in our state-of-the-art production facilities by our committed research and development team. We want to maximize your drilling efficiency while minimizing operational expenses.

Our Steel Body PDC Bit 4 Blades may be tailored to suit your specific needs in any industry, including oil and gas exploration, coal mining, and water well drilling. When you buy our products, you can be certain that they will function admirably in the worst drilling circumstances because we are dedicated to both quality and innovation.

Don't settle for subpar drilling equipment. Upgrade your operations with Shaanxi Hainaisen's premium Steel Body PDC Bit 4 Blades. Contact us today at hainaisen@hnsdrillbit.com to discuss your drilling challenges and discover how our advanced bit technology can transform your drilling operations. Let's work together to elevate your drilling performance and achieve new levels of efficiency and productivity!

References

1. Smith, J.R. (2021). Advanced PDC Bit Design for Enhanced Drilling Performance. Journal of Petroleum Technology, 73(5), 42-48.

2. Johnson, A.B., & Thompson, L.K. (2020). Wear Mechanisms in Polycrystalline Diamond Compact Cutters: A Comprehensive Review. SPE Drilling & Completion, 35(3), 270-285.

3. Chen, X., et al. (2019). Experimental Investigation on Wear Characteristics of Steel-Body PDC Bits in Abrasive Formations. Wear, 426-427, 1570-1581.

4. Williams, R.D., & Baker, R.C. (2018). Optimizing PDC Bit Performance Through Advanced Cutter Technology and Hydraulic Design. SPE/IADC Drilling Conference and Exhibition, SPE-189677-MS.

5. Anderson, M.E., & Azar, J.J. (2020). Real-Time Optimization of Drilling Parameters to Extend PDC Bit Life in Hard Rock Formations. Journal of Petroleum Science and Engineering, 185, 106633.

6. Thompson, G.L., et al. (2019). A Comprehensive Study on the Effects of Drilling Fluid Properties on PDC Bit Wear in Deep Horizontal Wells. SPE Drilling & Completion, 34(4), 368-382.