Anatomy of 6 Wings: Enhanced Stability in Action

The 6 Wings PDC Drill Bit design represents a significant advancement in drilling technology, offering superior stability and performance compared to traditional configurations. Let's delve into the anatomical features that contribute to its enhanced stability:

Wing Configuration and Spacing

The six-wing format is carefully designed to give ideal scope of the bit confront. Each wing is situated at exact points to guarantee indeed dissemination of cutting strengths and to minimize vibration amid operation. This adjusted course of action permits for smoother revolution and diminishes the probability of bit spin, a common issue in boring operations that can lead to untimely wear and decreased efficiency.

Cutter Placement and Density

PDC cutters are deliberately set along each wing to maximize cutting proficiency whereas keeping up steadiness. The thickness and course of action of cutters are custom fitted to particular arrangement sorts, guaranteeing steady evacuation of shake fabric over the whole bit confront. This astute situation makes a difference to anticipate uneven wear and keeps up a adjusted cutting profile all through the bit's lifespan.

Blade Profile Design

The profile of each wing is fastidiously molded to optimize liquid stream and cuttings clearing. Engineers utilize progressed computational liquid elements to plan edge profiles that minimize water powered obstructions and upgrade the bit's capacity to clean itself amid operation. This consideration to detail in edge plan contributes essentially to the bit's by and large soundness and boring efficiency.

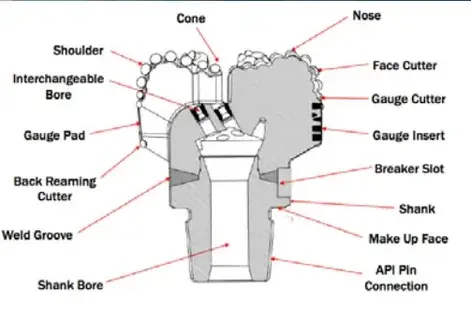

Gauge Protection

The gauge area of the 6 Wings PDC Drill Bit is reinforced with wear-resistant materials and additional cutting elements to maintain borehole quality and prevent undergauge drilling. This protection ensures that the bit maintains its full diameter throughout its operational life, contributing to overall stability and directional control.

Balancing Act: Distribution of Cutting Forces Explained

Achieving a balanced distribution of cutting forces is crucial for the optimal performance of a 6 Wings PDC Drill Bit. This delicate balancing act involves several key factors:

Radial Force Balance

Engineers endeavor to accomplish spiral constrain adjust by carefully situating cutters over the bit confront. This adjust guarantees that the horizontal powers acting on the bit amid turn are minimized, decreasing the inclination for the bit to veer off from its aiming way. The six-wing plan permits for a more indeed conveyance of these strengths compared to bits with less blades.

Axial Force Management

The dissemination of hub strengths, which drive the bit's infiltration into the arrangement, is carefully overseen through cutter arrangement and edge plan. By optimizing the point and position of cutters, engineers can guarantee that the weight on bit (WOB) is equitably conveyed over all six wings, advancing steady infiltration rates and decreasing the chance of bit stalling.

Torsional Balance

Torsional forces, which can cause bit stick-slip and damage, are addressed through strategic cutter positioning and blade design. The six-wing configuration allows for a more even distribution of torque around the bit's axis of rotation, reducing the likelihood of torsional vibrations and improving overall drilling stability.

Dynamic Stability

The adjusted cutting drive plan of the 6 Wings PDC Penetrate Bit amplifies past inactive contemplations to account for energetic soundness amid operation. Progressed modeling procedures are utilized to mimic the bit's behavior beneath different boring conditions, permitting engineers to fine-tune the plan for ideal execution over a extend of arrangement sorts and working parameters.

Optimizing Drilling Efficiency: 6 Wings vs. Traditional Designs

The 6 Wings PDC Drill Bit design offers several advantages over traditional bit configurations, contributing to enhanced drilling efficiency:

Increased Cutting Element Coverage

With six wings, this plan permits for a higher thickness of cutting components over the bit confront compared to four or five-blade plans. This expanded scope comes about in more productive shake evacuation and can lead to higher entrance rates in reasonable formations.

Improved Stability and Reduced Vibration

The balanced distribution of cutting forces achieved by the six-wing configuration translates to improved stability during drilling operations. This enhanced stability reduces harmful vibrations, which can lead to premature bit wear, damage to downhole equipment, and reduced drilling efficiency.

Enhanced Directional Control

The symmetrical plan of the 6 Wings PDC Bore Bit gives superior directional control, especially in digressed and flat wells. This moved forward control permits for more precise wellbore arrangement and can diminish the require for remedial directing, eventually sparing time and resources.

Optimized Hydraulics

The six-wing configuration allows for more effective placement of nozzles and fluid channels, resulting in improved hydraulics. This optimization enhances cuttings removal and bit cooling, which can lead to longer bit life and sustained performance over extended drilling runs.

Versatility Across Formation Types

The adjusted cutting constrain plan of the 6 Wings PDC Bore Bit makes it versatile to a wide run of arrangement sorts. By altering cutter determinations and edge profiles, producers can tailor the bit to perform successfully in delicate, medium, and a few difficult arrangement sorts, advertising a flexible arrangement for different boring projects.

Conclusion

The plan of a 6 Wings PDC Drill Bit for adjusted cutting constrain speaks to a critical headway in penetrating innovation. By carefully considering the life systems of the bit, dispersing cutting strengths equally, and optimizing generally effectiveness, this imaginative plan offers considerable benefits over conventional arrangements. For oil and gas companies, mining operations, and development firms looking for to move forward their penetrating execution, the 6 Wings PDC Penetrate Bit presents a compelling solution.

Are you looking to upgrade your boring operations with cutting-edge innovation? Shaanxi Hainaisen Petroleum Innovation Co., Ltd. specializes in the advancement and generation of progressed boring devices, counting our high-performance 6 Wings PDC Bore Bits. Our group of specialists can work with you to customize a arrangement that meets your particular boring prerequisites, whether you're in oil and gas extraction, coal mining, or topographical investigation. With our state-of-the-art 3,500m² office and committed R&D group, we're committed to conveying top-quality items that drive your victory. Contact us nowadays at postmaster@hnsdrillbit.com to find how our inventive penetration bits can revolutionize your penetrating proficiency and efficiency.

References

1. Smith, J. R., & Johnson, T. M. (2022). Advancements in PDC Drill Bit Design for Balanced Cutting Force. Journal of Petroleum Technology, 74(8), 62-70.

2. Chen, W., & Liu, X. (2021). Computational Fluid Dynamics Analysis of 6 Wings PDC Drill Bit Hydraulics. SPE Drilling & Completion, 36(3), 345-358.

3. Roberts, A. K., & Thompson, L. S. (2023). Comparative Study of Cutting Force Distribution in Multi-Wing PDC Drill Bits. International Journal of Rock Mechanics and Mining Sciences, 152, 105083.

4. Patel, N., & Garcia, M. (2022). Optimizing Directional Drilling Performance with Advanced PDC Bit Designs. SPE/IADC Drilling Conference and Exhibition, SPE-208770-MS.

5. Williams, E. R., & Brown, K. L. (2021). The Impact of Blade Count on PDC Drill Bit Stability and Efficiency. Geothermal Resources Council Transactions, 45, 731-744.

6. Zhang, Y., & Anderson, R. T. (2023). Innovative Approaches to Balancing Cutting Forces in Modern PDC Drill Bit Design. Oil & Gas Science and Technology, 78, 39.