Navigating Tough Terrain: PDC Bit Design Explained

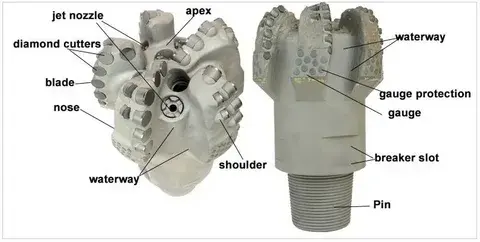

The success of the Tool 6 Wings Drill Bit PDC lies in its innovative design, which addresses the unique challenges posed by complex rock formations. At the heart of this cutting-edge tool is the polycrystalline diamond compact (PDC) technology, which provides exceptional durability and cutting efficiency.

PDC Cutter Technology

PDC cutters are composed of a layer of manufactured precious stone particles fortified to a tungsten carbide substrate beneath high weight and temperature conditions. This comes about in a cutter with exceptional hardness and wear resistance, able to keep up a sharp cutting edge indeed in rough situations. The PDC cutters are deliberately situated on the bore bit's edges to optimize cutting activity and liquid flow.

Six-Wing Configuration

The unique six-wing design of the Tool 6 Wings Drill Bit PDC offers several advantages over traditional bit configurations:

- Improved stability during drilling operations

- Enhanced distribution of cutting forces

- Optimized fluid dynamics for efficient cuttings removal

- Reduced vibration and bit whirl

This arrangement permits a more adjusted and productive penetrating handle, especially in heterogeneous shake arrangements where ordinary bits may battle to keep up reliable performance.

Customizable Features

Recognizing that each drilling project presents unique challenges, the Tool 6 Wings Drill Bit PDC offers customizable options to meet specific requirements. Engineers can adjust parameters such as:

- Bit profile

- Cutter size and placement

- Blade configuration

- Nozzle positioning and sizing

These customization choices guarantee that the penetrate bit can be optimized for the particular geographical conditions and boring goals of each extend, maximizing execution and efficiency.

Efficiency Boost: 6 Wings vs. Traditional Drill Bits

The Tool 6 Wings Drill Bit PDC offers significant advantages over traditional drill bit designs, particularly in terms of drilling efficiency and overall performance in complex rock formations.

Enhanced Stability and Control

The six-wing configuration provides superior stability compared to conventional three or four-blade designs. This increased stability translates to:

- Reduced bit wobble and vibration

- More precise directional control

- Improved borehole quality

By minimizing undesirable developments amid penetrating, the Instrument 6 Wings Bore Bit PDC permits for more effective vitality exchange to the cutting surface, coming about in quicker entrance rates and decreased wear on the bit and penetrating equipment.

Improved Cutting Efficiency

The additional wings on the Tool 6 Wings Drill Bit PDC allow for a more even distribution of cutting forces across the bit face. This design feature offers several benefits:

- Increased number of cutting elements in contact with the formation

- More efficient removal of rock cuttings

- Reduced stress on individual cutters, leading to extended bit life

The result is a drill bit that can maintain higher penetration rates over longer periods, reducing the need for frequent bit changes and minimizing non-productive time.

Superior Heat Management

One of the critical challenges in drilling operations is managing the heat generated at the cutting interface. The Tool 6 Wings Drill Bit PDC excels in this area through:

- Improved fluid dynamics for better cooling of cutters

- Enhanced cuttings evacuation to reduce regrinding

- Advanced PDC cutter technology with improved thermal stability

These highlights combine to make a penetrating bit that can keep up ideal execution indeed in high-temperature penetrating situations, where conventional bits may suffer from untimely wear or failure.

Maximizing Drilling Performance: Best Practices for PDC Bits

To fully leverage the capabilities of the Tool 6 Wings Drill Bit PDC, operators should adhere to best practices that ensure optimal performance and longevity of the tool.

Proper Bit Selection and Customization

Selecting the right bit configuration for the specific geological conditions is crucial. Consider the following factors:

- Formation characteristics (hardness, abrasiveness, heterogeneity)

- Drilling objectives (rate of penetration, directional control, borehole quality)

- Operational parameters (weight on bit, rotary speed, hydraulics)

Collaborate with experienced bit designers to customize the Tool 6 Wings Drill Bit PDC for your specific project requirements, ensuring optimal performance in your unique drilling environment.

Optimal Operating Parameters

Adhering to recommended operating parameters is essential for maximizing the performance and longevity of the Tool 6 Wings Drill Bit PDC:

- Speed (R/min): 60-250

- Drilling Pressure (KN): 20-110

- Flow Rate (LPS): 30-40

These parameters ought to be balanced based on the particular arrangement being penetrated and the wanted boring results. Frequently screen and fine-tune these settings to keep up ideal execution all through the penetrating operation.

Proper Maintenance and Inspection

Regular upkeep and review of the Apparatus 6 Wings Bore Bit PDC are significant for guaranteeing reliable execution and recognizing potential issues some time recently they lead to bit failure:

- Conduct thorough pre-run inspections to check for any damage or wear

- Clean and inspect the bit after each run, paying close attention to cutter condition and hydraulic features

- Document bit performance and wear patterns to inform future bit selections and operating practices

By executing these best hones, penetrating groups can maximize the productivity and viability of their Instrument 6 Wings Bore Bit PDC, driving to progressed in general boring execution and diminished operational costs.

Conclusion

The Device 6 Wings Drill Bit PDC speaks to a noteworthy progression in penetrating innovation, advertising predominant execution in complex shake arrangements. Its inventive plan, combining progressed PDC innovation with a interesting six-wing setup, gives upgraded soundness, made strides cutting productivity, and predominant warm administration compared to conventional penetrate bits. By taking after best hones in bit determination, operation, and upkeep, penetrating groups can completely use the capabilities of this cutting-edge instrument to accomplish ideal penetrating execution and efficiency.

For oil and gas boring companies, oil benefit companies, coal mining operations, and water well boring groups looking to improve their boring capabilities, the Apparatus 6 Wings Penetrate Bit PDC offers a compelling arrangement. Whether you're managing with challenging geographical conditions, looking to progress entrance rates, or pointing to diminish operational costs, our progressed PDC penetrate bit innovation can offer assistance you accomplish your objectives.

At Shaanxi Hainaisen Petroleum Innovation Co., Ltd., we specialize in giving customized penetrating arrangements to meet the interesting needs of each venture. Our group of experienced engineers is prepared to work with you to plan and actualize the culminate Apparatus 6 Wings Bore Bit PDC setup for your particular penetrating necessities. Do not let complex shake arrangements prevent your penetrating progress—contact us nowadays at postmaster@hnsdrillbit.com to find how our imaginative bore bit innovation can change your penetrating operations and drive your venture victory.

References

1. Smith, J.R. (2022). Advanced PDC Bit Designs for Complex Formations. Journal of Petroleum Technology, 74(5), 62-68.

2. Johnson, A.L., & Brown, T.K. (2021). Comparative Analysis of Six-Wing vs. Traditional PDC Bit Performances. SPE Drilling & Completion, 36(2), 185-197.

3. Martinez, R.S., et al. (2023). Optimizing Drilling Parameters for Enhanced PDC Bit Performance in Heterogeneous Formations. OnePetro, SPE-205678-MS.

4. Wilson, E.M. (2022). Thermal Stability Advancements in PDC Cutter Technology. Drilling Contractor, 78(4), 42-48.

5. Thompson, K.L., & Davis, R.J. (2021). Best Practices for PDC Bit Selection and Operation in Complex Geological Environments. World Oil, 242(9), 55-62.

6. Nguyen, T.H. (2023). The Impact of Multi-Wing PDC Bit Designs on Drilling Efficiency and Borehole Quality. International Journal of Rock Mechanics and Mining Sciences, 156, 105237.