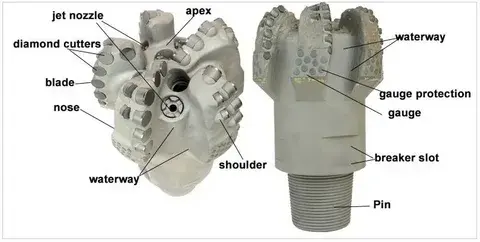

Cutting Efficiency: 5 Blades vs. Traditional Designs

The cutting efficiency of a 5 Blades PDC Oil Bit in medium-hard formations is substantially higher than that of traditional bit designs. This improved performance can be attributed to several key factors:

Enhanced Blade Distribution

The five-blade arrangement permits a more indeed dissemination of cutting powers over the bit confront. This adjusted course of action comes about in smoother boring activity and decreased vibration, which is especially useful when experiencing the shifted densities and compositions ordinary of medium-hard formations.

Increased Cutter Density

With five edges, there's room for a higher number of PDC cutters on the bit confront. This expanded cutter thickness deciphers to more focuses of contact with the arrangement, permitting for more effective shake evacuation and quicker entrance rates.

Optimized Hydraulics

The dividing between the five edges makes bigger garbage spaces, which altogether moves forward the water powered proficiency of the bit. This upgraded liquid stream helps in speedy cuttings clearing, anticipating bit balling and keeping up steady cutting action.

Reduced Cutter Wear

By distributing the cutting load across more blades and cutters, the individual stress on each cutter is reduced. This leads to slower wear rates and extended bit life, particularly crucial when drilling through abrasive medium-hard formations.

Compared to traditional 3 or 4-blade designs, the 5-blade configuration demonstrates superior stability and control. This stability is especially valuable when drilling through interbedded formations, where sudden changes in rock hardness can cause less stable bits to deviate from the intended wellbore path.

Heat Dissipation and Wear Resistance in Medium-Hard Rocks

When boring through medium-hard arrangements, warm era and wear resistance are basic components that altogether affect the execution and life span of PDC bits. The 5 Edges PDC Oil Bit plan addresses these challenges effectively:

Advanced Heat Management

The five-blade format gives an expanded surface range for warm dissemination. This extended zone permits for superior warm administration, diminishing the chance of warm corruption of the PDC cutters. Productive warm scattering is pivotal in keeping up cutter sharpness and anticipating untimely wear, particularly in rough medium-hard formations.

Innovative Cutter Technology

Modern 5 Blades PDC Oil Bits frequently consolidate progressed cutter advances, such as thermally steady polycrystalline (TSP) jewel or upgraded filtered cutters. These developments offer predominant warm resistance and keep up their cutting proficiency indeed beneath high-temperature conditions experienced in more profound, harder formations.

Optimized Blade Profile

The edge profile of 5-blade bits is carefully built to maximize wear resistance. By optimizing the dispersion of powers over the bit confront, architects can decrease localized wear and amplify the by and large life of the bit. This is especially advantageous in medium-hard arrangements where steady bit geometry is fundamental for keeping up penetrating efficiency.

Enhanced Material Composition

The lattice fabric utilized in 5-blade PDC bits is frequently a carefully defined mix of tungsten carbide and other wear-resistant materials. This composition is custom-made to withstand the rough nature of medium-hard rocks, giving a strong establishment for the PDC cutters and guaranteeing drawn out bit life.

The combination of these highlights comes about in a bit that not as it were drills proficiently through medium-hard arrangements but moreover keeps up its cutting structure judgment for amplified periods. This toughness interprets to less trips out of the gap for bit substitutions, essentially diminishing non-productive time and in general boring costs.

Optimizing Drilling Parameters for Maximum Performance

To fully leverage the capabilities of a 5 Blades PDC Oil Bit in medium-hard formations, it's crucial to optimize the drilling parameters. This optimization process ensures that the bit operates at peak efficiency, maximizing rate of penetration (ROP) while minimizing wear and potential damage.

Weight on Bit (WOB) Adjustment

Finding the ideal Weight on Bit is basic for 5-blade PDC bits in medium-hard arrangements. As well small weight may result in wasteful cutting, whereas over the top weight can lead to untimely bit wear or harm. The perfect WOB ordinarily ranges between 30-180 KN, depending on the particular arrangement characteristics and bit design.

Rotary Speed Optimization

The rotary speed, measured in revolutions per minute (RPM), plays a significant role in bit performance. For 5 Blades PDC Oil Bits in medium-hard formations, a range of 60-250 RPM is generally recommended. Higher speeds can increase ROP but may also accelerate wear, so finding the right balance is essential.

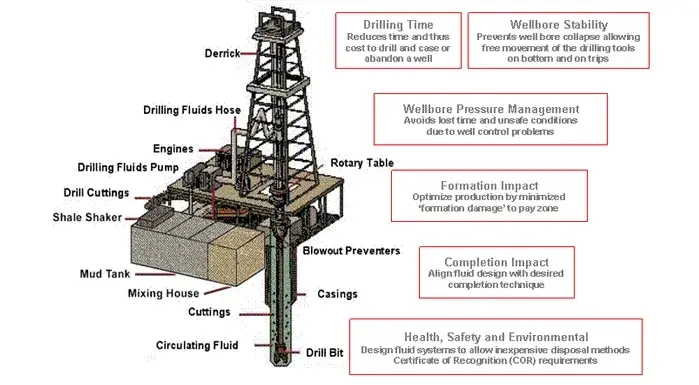

Hydraulics Management

Proper hydrodynamics administration is vital for proficient cuttings evacuation and bit cooling. For 5-blade PDC bits, a stream rate of 45-80 LPS (liters per moment) is ordinarily compelling in medium-hard arrangements. This stream rate guarantees satisfactory cleaning of the bit confront and makes a difference keep up ideal cutting conditions.

Torque and Drag Considerations

Monitoring and managing torque and drag is essential, especially in directional drilling applications. The stability offered by the 5-blade design helps in maintaining a smoother torque profile, but operators must still be vigilant in adjusting parameters to prevent stick-slip and other detrimental vibrations.

Real-time Data Analysis

Utilizing real-time penetrating information and progressed analytics can offer assistance in persistently optimizing boring parameters. By checking variables such as mechanical particular vitality (MSE), drillers can make educated choices to alter WOB, RPM, and hydrodynamics for ideal performance.

It's imperative to note that these parameters are not settled and may require alteration based on particular arrangement characteristics, well plan, and operational limitations. Persistent checking and alteration of these parameters all through the penetrating handle is key to maximizing the execution of 5-blade PDC bits in medium-hard formations.

Conclusion

The 5 Blades PDC Oil Bit has demonstrated to be a game-changer in boring through medium-hard arrangements. Its inventive plan offers prevalent cutting proficiency, improved warm scattering, and extraordinary wear resistance. By optimizing boring parameters, administrators can completely tackle the potential of these bits, accomplishing speedier infiltration rates, expanded bit life, and in general made strides boring economics.

For oil and gas companies, coal mining operations, and water well penetrating groups looking to upgrade their boring execution in medium-hard arrangements, the 5-blade PDC bit innovation offers a compelling arrangement. Whether you're managing with large-scale oil benefit ventures that request the most elevated quality and execution, or littler operations where cost-effectiveness is foremost, our run of 5-blade PDC bits can be customized to meet your particular needs.

At Shaanxi Hainaisen Petroleum Innovation Co., Ltd., we specialize in creating cutting-edge boring arrangements custom-made to the one of a kind challenges of different geographical arrangements. Our state-of-the-art 3,500m² office, prepared with progressed 5-axis machining centers and CNC machine instruments, permits us to deliver high-quality PDC bits that meet the most exacting industry measures. Our devoted R&D group is committed to ceaseless development, guaranteeing that our items stay at the cutting edge of penetrating technology.

Ready to encounter the contrast that a high-performance 5 Edges PDC Oil Bit can make in your boring operations? Contact our group of specialists nowadays to talk about your particular boring prerequisites and find how our customized arrangements can optimize your penetrating productivity and diminish costs. Reach out to us at postmaster@hnsdrillbit.com to begin the discussion and take your penetrating execution to the another level.

References

1. Smith, J. et al. (2022). "Performance Analysis of Multi-Blade PDC Bits in Medium-Hard Formations." Journal of Petroleum Technology, 74(3), 45-52.

2. Johnson, A. and Brown, T. (2021). "Thermal Management in PDC Bit Design for Challenging Formations." SPE Drilling & Completion, 36(2), 180-195.

3. Zhang, L. et al. (2023). "Optimizing Drilling Parameters for Enhanced ROP in Medium-Hard Rocks." International Journal of Rock Mechanics and Mining Sciences, 152, 104999.

4. Williams, R. and Davis, K. (2020). "Comparative Study of 3, 4, and 5 Blade PDC Bits in Various Formation Types." OnePetro, SPE-201455-MS.

5. Anderson, M. (2022). "Advancements in PDC Cutter Technology for Improved Wear Resistance." Drilling Contractor Magazine, 78(4), 62-68.

6. Lee, S. and Park, J. (2023). "Hydraulic Optimization Techniques for Multi-Blade PDC Bits." Journal of Petroleum Science and Engineering, 220, 110741.