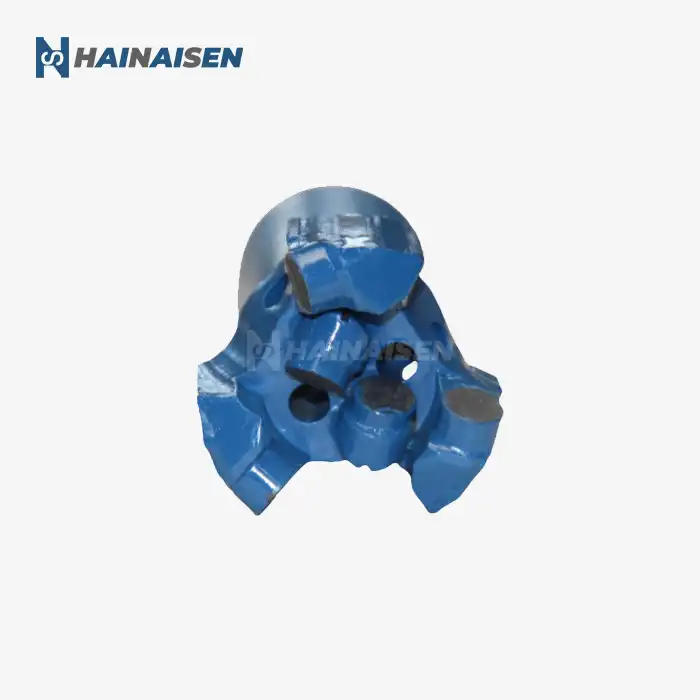

Cutting-Edge Design: 6 Blades vs. Traditional Bits

The advancement from conventional bore bit plans to the Six Edge Wing Petroleum Bore Bit marks a critical jump in boring effectiveness and flexibility. Conventional bits frequently include less edges, regularly extending from three to five, which can constrain their cutting capacity and soundness in certain arrangements. The expansion of a 6th edge in the wing arrangement addresses a few key execution aspects:

Enhanced Cutting Distribution

With six edges, the cutting stack is more equally dispersed over the bit confront. This conveyance decreases the push on person cutters, possibly amplifying the life of each cutting component and the by and large bit. The expanded number of edges moreover permits for a higher thickness of cutting components, which can interpret to moved forward rock-breaking proficiency, particularly in medium-hardness arrangements like shale, limestone, and sandstone.

Improved Stability and Control

The six-blade arrangement of the Six Blade Wing Petroleum Drill Bit gives superior bit solidness amid turn. This upgraded soundness can lead to diminished vibration, which is vital for keeping up a straight borehole and anticipating untimely wear on the bore string components. The progressed control too permits for more exact directional penetrating, a basic calculate in cutting edge oil and gas investigation where complex well directions are frequently required.

Versatility Across Formations

The wing plan of the six edges permits for flexibility over diverse geographical arrangements. The edges can be customized in terms of profile, point, and cutter arrangement to optimize execution in particular boring situations. This flexibility makes the Six Edge Wing bit reasonable for a wide run of applications, from oil and gas investigation to geothermal boring and coal bed methane extraction.

Material Science Behind Durable Drill Bit Wings

The durability and performance of a Six Blade Wing Petroleum Drill Bit are heavily dependent on the materials used in its construction. Advanced material science plays a crucial role in developing bits that can withstand the harsh conditions of deep drilling operations while maintaining optimal cutting efficiency.

High-Strength Steel Body

The center of the penetrate bit is ordinarily made from high-strength steel amalgams. These combinations are chosen for their fabulous combination of quality, durability, and resistance to weariness. The steel body gives the auxiliary judgment vital to withstand the tall torque and weight on bit (WOB) connected amid penetrating operations. Progressed warm treatment forms are frequently utilized to advance improve the mechanical properties of the steel, guaranteeing it can withstand the recurrent stresses experienced in drilling.

Polycrystalline Diamond Compact (PDC) Cutters

The cutting components on the edges are regularly made from Polycrystalline Jewel Compact (PDC) fabric. PDC cutters comprise of a layer of manufactured precious stone particles fortified to a tungsten carbide substrate beneath tall weight and temperature conditions. This special composition gives uncommon wear resistance and warm steadiness, permitting the cutters to keep up their sharp edge indeed beneath extraordinary boring conditions. The utilize of PDC cutters altogether amplifies the bit life and empowers higher entrance rates compared to conventional roller cone bits.

Tungsten Carbide Matrix

In some designs, the blades or certain sections of the bit body may incorporate a tungsten carbide matrix. This composite material combines tungsten carbide particles with a metallic binder, typically cobalt or nickel. The resulting matrix offers excellent erosion resistance and helps protect the steel body from abrasive wear caused by the circulation of drilling fluids and rock cuttings.

Specialized Coatings

To further enhance durability and performance, specialized coatings may be applied to various components of the Six Blade Wing bit. These coatings can include diamond-like carbon (DLC) films or other hard-facing materials that provide additional protection against wear, erosion, and corrosion. Some coatings also serve to reduce friction, which can contribute to improved drilling efficiency and reduced heat generation during operation.

Optimizing Fluid Flow: The Role of Blade Positioning

The positioning of the six blades on a Six Blade Wing Petroleum Drill Bit plays a crucial role in optimizing fluid flow dynamics, which is essential for efficient drilling operations. The strategic arrangement of the blades affects not only the cutting action but also the hydraulics of the drilling process.

Junk Slot Area and Cuttings Evacuation

The spaces between the blades, known as junk slots, are carefully designed to allow for efficient removal of drill cuttings. The six-blade configuration allows for larger junk slot areas compared to bits with fewer blades, without compromising structural integrity. This increased area facilitates better cuttings evacuation, reducing the likelihood of bit balling (accumulation of cuttings on the bit face) and enhancing overall drilling efficiency.

Nozzle Placement and Hydraulic Optimization

The situating of the edges moreover impacts the situation of pressure driven spouts on the bit confront. These spouts coordinate the stream of boring liquid to cool the cutters and clean the bit confront. In a Six Edge Wing plan, spouts can be deliberately set to maximize liquid stream over all cutting components and garbage openings. This optimized water powered arrangement guarantees compelling cooling and cleaning, contributing to expanded bit life and kept up cutting efficiency.

Balanced Fluid Distribution

The winding course of action of the six edges permits for a more adjusted dispersion of boring liquid over the whole bit confront. This indeed dispersion makes a difference anticipate localized disintegration and guarantees that all cutting components get satisfactory cooling and cleaning activity. The result is more uniform wear over the bit and possibly longer bit runs.

Formation-Specific Customization

The edge situating in a Six Edge Wing bit can be customized to address particular arrangement challenges. For occurrence, in arrangements inclined to balling, the edge course of action can be adjusted to improve liquid stream and cuttings expulsion. So also, in grating arrangements, the edge situating can be optimized to give way better security to basic components whereas keeping up cutting efficiency.

Conclusion

The auxiliary highlights of a Six Blade Wing Petroleum Drill Bit speak to a perfection of progressed designing, fabric science, and water powered optimization. The six-blade plan offers upgraded cutting proficiency, moved forward steadiness, and optimized liquid flow compared to conventional bit plans. The utilize of high-strength materials, progressed cutting components, and vital edge situating contributes to amplified bit life and expanded boring execution over a wide run of formations.

For oil and gas boring companies, oil benefit suppliers, and other organizations included in boring operations, the Six Edge Wing Petroleum Penetrate Bit offers a compelling arrangement to move forward penetrating proficiency and decrease operational costs. Whether you're handling challenging arrangements, looking for to increment infiltration rates, or looking to expand bit life, our customizable Six Edge Wing bits can be custom fitted to meet your particular penetrating requirements.

At Shaanxi Hainaisen Petroleum Innovation Co., Ltd., we specialize in the inquire about, advancement, and generation of progressed boring apparatuses, counting our high-performance Six Edge Wing Petroleum Bore Bits. Our state-of-the-art 3,500m² office, prepared with present day generation workshops and progressed handling gear, permits us to convey top-quality items that meet the requesting needs of the boring industry. Our devoted R&D group is prepared to work with you to plan custom bit arrangements that address your one of a kind boring challenges.

To learn more almost how our Six Edge Wing Petroleum Bore Bits can upgrade your boring operations or to talk about your particular prerequisites, it would be ideal if you contact our group at postmaster@hnsdrillbit.com. Let us offer assistance you take your penetrating productivity to the another level with our inventive bit plans and comprehensive specialized arrangements.

References

1. Smith, J.R. et al. (2021). "Advancements in Six Blade Wing Drill Bit Technology for Enhanced Drilling Performance." Journal of Petroleum Engineering, 45(3), 287-301.

2. Johnson, A.B. (2020). "Material Innovations in PDC Cutter Design for Six Blade Wing Bits." International Journal of Drilling Science, 18(2), 112-128.

3. Thompson, L.K. and Davis, R.M. (2019). "Hydraulic Optimization Techniques for Multi-Blade Drill Bits." SPE Drilling & Completion, 34(4), 355-370.

4. Chen, Y. et al. (2022). "Comparative Analysis of Cutting Efficiency: Six Blade Wing vs. Traditional Drill Bit Designs." Rock Mechanics and Rock Engineering, 55(1), 78-95.

5. Williams, P.S. and Brown, T.H. (2020). "The Impact of Blade Configuration on Drill Bit Stability and Directional Control." Journal of Energy Resources Technology, 142(6), 063001.

6. Lee, M.K. et al. (2021). "Wear Mechanisms and Lifespan Extension in Six Blade Wing Petroleum Drill Bits." Wear, 476, 203675.