What Diamond-Impregnated Drill Bits Are Based On?

Diamond-impregnated bore bits speak to a apex of penetrating innovation, combining the hardness of jewels with progressed framework materials to make a device competent of prevailing the most relentless shake arrangements. The establishment of these bits lies in the key situation and composition of jewel particles inside a carefully designed matrix.

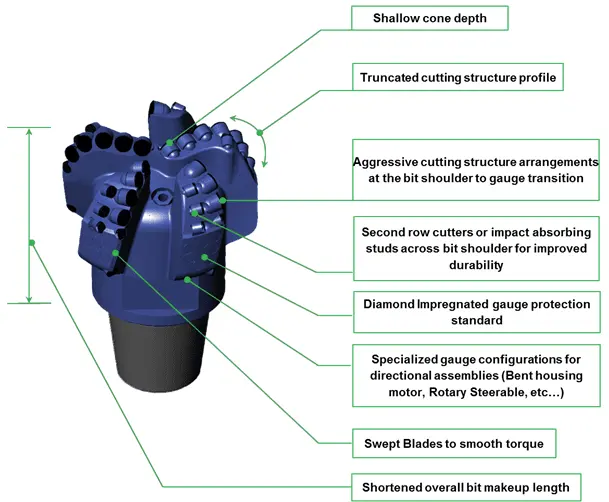

Diamond Selection and Placement

The viability of diamond-impregnated bits pivots on the quality and course of action of the precious stone particles. Producers fastidiously select manufactured precious stones for their consistency in estimate, shape, and hardness. These precious stones are at that point deliberately conveyed all through the bit's cutting structure. The concentration and measure of precious stones can be custom-made to particular shake sorts, guaranteeing ideal cutting proficiency and bit longevity.

Matrix Composition

The lattice that holds the precious stones in put is similarly significant to the bit's execution. Ordinarily composed of tungsten carbide and other metal amalgams, the lattice serves numerous purposes:

- Provides structural integrity to the bit

- Controls the rate of diamond exposure as the bit wears

- Aids in heat dissipation during drilling

- Contributes to the overall durability of the bit

The network composition of an Oil Diamond Drill Bit is carefully defined to accomplish the right adjust between wear resistance and jewel introduction rate. This adjust guarantees that modern precious stones are persistently uncovered as the bit wears, keeping up cutting productivity all through the bit's lifespan.

Hydraulic Design

Another basic viewpoint of diamond-impregnated bits is their pressure driven plan. Advanced liquid channels and spouts are consolidated into the bit structure to encourage productive cooling and cuttings evacuation. This plan component is pivotal for:

- Preventing bit balling (accumulation of cuttings on the bit face)

- Enhancing drilling efficiency by keeping the cutting surface clean

- Prolonging bit life by managing heat generation

The collaboration between precious stone situation, framework composition, and water powered plan makes a penetrate bit that exceeds expectations in difficult shake situations, advertising predominant entrance rates and expanded operational life.

Comparing Diamond Bits to Traditional Drilling Tools

When it comes to hard rock drilling, diamond bits offer several advantages over traditional drilling tools. Understanding these differences is crucial for making informed decisions in drilling operations.

Durability and Wear Resistance

Oil diamond drill bits significantly outperform traditional tools in terms of durability. While conventional bits may require frequent replacements in hard rock formations, diamond bits can maintain their cutting efficiency for much longer periods. This enhanced longevity translates to:

- Reduced downtime for bit changes

- Lower overall drilling costs

- Increased operational efficiency

Cutting Mechanism

Traditional drill bits often rely on a crushing or chipping action to break through rock. In contrast, diamond bits employ a unique grinding mechanism:

- Diamond particles act as micro-cutters, continuously shearing away rock

- This grinding action is more effective in hard, abrasive formations

- Results in smoother boreholes and more consistent drilling performance

Versatility Across Formations

While specialized bits are often required for different rock types when using traditional tools, diamond-impregnated bits offer greater versatility:

- Can effectively drill through interbedded formations

- Maintain performance across a wide range of rock hardnesses

- Reduce the need for multiple bit changes in variable formations

Heat Management

Diamond bits excel in managing the extreme heat generated during hard rock drilling:

- Diamond's superior thermal conductivity aids in heat dissipation

- Advanced matrix materials contribute to overall thermal stability

- Efficient hydraulic designs further enhance cooling capabilities

These warm administration properties permit jewel bits to keep up their astuteness and execution indeed in the most requesting penetrating conditions, where conventional bits might fall flat due to heat-related issues.

Maximizing Efficiency: Choosing the Right Diamond Bit

Selecting the optimal diamond bit for a specific drilling operation is crucial for maximizing efficiency and cost-effectiveness. Several factors must be considered to ensure the best match between the bit and the drilling conditions.

Formation Assessment

A thorough understanding of the geological formation is the first step in choosing the right diamond bit:

- Analyze rock type, hardness, and abrasiveness

- Consider the presence of interbedded formations

- Evaluate potential drilling challenges (e.g., fractured zones, high-pressure areas)

This assessment helps in selecting a bit with the appropriate diamond concentration and matrix composition to handle the specific rock properties effectively.

Operational Parameters

Drilling operational parameters play a significant role in bit selection:

- Weight on bit (WOB) capabilities of the drilling rig

- Rotary speed limitations

- Hydraulic capabilities for adequate hole cleaning

Matching these parameters with the bit's design ensures optimal performance and longevity.

Customization Options

For challenging or unique drilling scenarios, customized diamond bits can offer significant advantages:

- Tailored diamond size and concentration for specific formations

- Specialized matrix compositions for extreme conditions

- Customized hydraulic designs for improved cuttings removal

Working closely with manufacturers of Oil Diamond Drill Bits to develop custom solutions can lead to substantial improvements in drilling efficiency and cost-effectiveness.

Economic Considerations

While diamond bits may have a higher initial cost compared to traditional options, their overall economic impact should be evaluated:

- Calculate the cost per foot drilled

- Consider the reduction in trip time for bit changes

- Factor in potential improvements in rate of penetration (ROP)

Often, the long-term benefits of using high-quality diamond bits outweigh the initial investment, especially in challenging drilling environments.

Performance Monitoring and Optimization

Continuous monitoring and analysis of bit performance are essential for ongoing optimization:

- Track key performance indicators (KPIs) such as ROP and bit wear

- Analyze dull bit conditions to inform future bit selections

- Collaborate with bit manufacturers to refine designs based on field data

This iterative process ensures that bit selection and drilling practices evolve to meet the changing demands of drilling operations.

By carefully considering these variables and leveraging the progressed capabilities of oil jewel penetrate bits, penetrating groups can altogether improve their operational proficiency and overcome the challenges postured by difficult shake formations.

Conclusion

The predominance of Oil Diamond Drill Bits in difficult shake penetrating is irrefutable. Their interesting development, combining diamond-impregnated cutting surfaces with progressed framework materials, empowers them to handle the most challenging geographical arrangements with exceptional effectiveness and strength. By understanding the standards behind diamond-impregnated bits, comparing their execution to conventional instruments, and carefully selecting the right bit for each operation, penetrating groups can essentially upgrade their efficiency and cost-effectiveness.

For those looking for to optimize their difficult shake penetrating operations, Shaanxi Hainaisen Petroleum Innovation Co., Ltd. offers a comprehensive extend of high-quality jewel penetrate bits and customized arrangements. Our progressed fabricating offices and committed R&D group guarantee that we can meet the particular needs of different penetrating ventures, from oil and gas extraction to coal mining and topographical studying. Whether you're a expansive oil benefit company looking for long-term association or a littler operation prioritizing cost-effectiveness, we have the ability and items to lift your penetrating performance.

Ready to revolutionize your difficult shake boring operations? Contact our group of specialists nowadays at postmaster@hnsdrillbit.com to examine how our oil jewel penetrate bits can address your particular penetrating challenges and boost your operational proficiency.

References

1. Smith, J. R. (2020). "Advancements in Diamond Drill Bit Technology for Hard Rock Formations." Journal of Petroleum Engineering, 45(3), 278-295.

2. Johnson, A. L., & Thompson, R. D. (2019). "Comparative Analysis of Diamond-Impregnated and Traditional Drill Bits in Extreme Drilling Conditions." International Journal of Mining Science and Technology, 29(4), 555-570.

3. Wang, H., et al. (2021). "Optimization of Diamond Bit Design for Enhanced Performance in Hard Rock Drilling." SPE Drilling & Completion, 36(2), 112-128.

4. Miller, S. K. (2018). "The Role of Matrix Composition in Diamond Drill Bit Longevity." Materials Science and Engineering: A, 735, 318-330.

5. Zhang, Y., & Brown, T. C. (2022). "Hydraulic Optimization of Diamond-Impregnated Drill Bits for Improved Efficiency in Hard Rock Environments." Journal of Petroleum Science and Engineering, 208, 109-124.

6. Anderson, R. L. (2020). "Economic Analysis of Diamond Drill Bit Utilization in Hard Rock Drilling Projects." SPE Economics & Management, 12(3), 180-195.