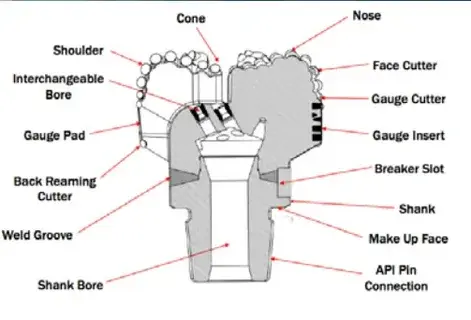

Diamond Matrix: The Cutting Edge Explained

The precious stone network is the heart of any jewel penetrate bit, serving as the essential cutting surface that straightforwardly interatomic with the shake arrangement. This network comprises of manufactured precious stone particles inserted in a metal amalgam, ordinarily composed of tungsten carbide and other strong materials. The composition and course of action of precious stones inside the network essentially impact the bit's cutting capacity and wear resistance.

Diamond Particle Selection and Distribution

The measure, quality, and dissemination of jewel particles inside the lattice of diamond drill bits for oil rigs are carefully designed to optimize cutting execution. Bigger precious stones give forceful cutting activity for harder arrangements, whereas littler particles offer a more refined cutting surface for gentler rocks. The concentration of jewels in the framework, moreover, shifts depending on the aiming application, with higher concentrations ordinarily utilized for harder formations.

Matrix Material Composition

The metal amalgam that ties the jewel particles plays a pivotal part in the bit's by and large execution. This network fabric must strike a adjust between wear resistance and controlled disintegration to persistently uncover new cutting surfaces. Progressed cover materials are utilized to upgrade the matrix's warm solidness and toughness, guaranteeing reliable execution indeed beneath extraordinary penetrating conditions.

Innovative Matrix Designs

Leading producers are always creating unused lattice details and plans to make strides boring effectiveness. These advancements incorporate layered framework structures, variable precious stone concentrations over the bit confront, and specialized impregnation methods that optimize the adjust between cutting forcefulness and bit longevity.

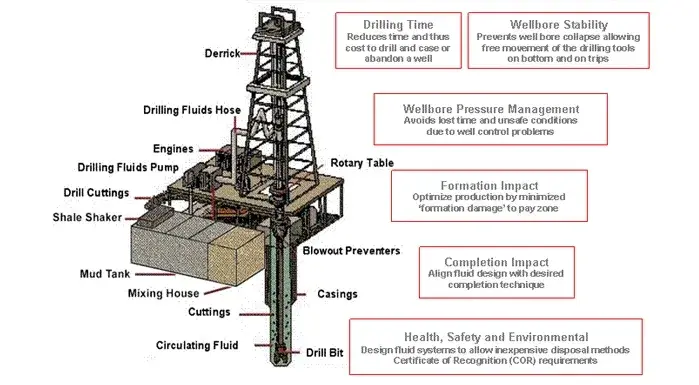

Fluid Channels: Optimizing Drilling Efficiency

Fluid channels, also known as junk slots or waterways, are integral components of diamond drill bits that significantly impact drilling efficiency. These channels are designed to facilitate the flow of drilling fluid, which serves multiple critical functions during the drilling process.

Cooling and Lubrication

One of the essential capacities of liquid channels is to coordinate boring liquid to the cutting surface, giving fundamental cooling and grease. This makes a difference anticipate overheating of the precious stone network and decreases contact between the bit and the shake arrangement, eventually amplifying the bit's life expectancy and keeping up cutting efficiency.

Debris Removal and Hole Cleaning

Efficient flotsam and jetsam expulsion is vital for keeping up penetrating speed and avoiding bit balling. Well-designed liquid channels in Diamond Drill Bits For Oil Rigs create a pressure driven activity that lifts cuttings absent from the bit confront and transports them up the borehole. This persistent cleaning activity ensures that new shake is continuously exposed to the cutting surface, maximizing infiltration rates.

Hydraulic Optimization

The setup of liquid channels is carefully designed to optimize water powered execution. Components such as channel estimate, shape, and situation are custom fitted to particular penetrating conditions and bit plans. Progressed computational liquid elements (CFD) modeling is frequently utilized to fine-tune these parameters, guaranteeing ideal liquid stream over the whole bit face.

Choosing the Right Diamond Bit: 3 Key Factors

Selecting the appropriate diamond drill bit for oil rigs is crucial for maximizing drilling efficiency and reducing overall project costs. When choosing a bit, drilling engineers and purchasing managers should consider three key factors:

Formation Characteristics

Understanding the topographical properties of the target arrangement is vital. Components such as shake hardness, abrasiveness, and compressive quality direct the most reasonable jewel concentration, lattice composition, and cutting structure. For occurrence, milder arrangements may require bits with lower jewel concentrations and more forceful cutting structures, whereas harder arrangements require higher jewel concentrations and more wear-resistant matrices.

Operational Parameters

Drilling operational parameters, counting weight on bit (WOB), revolving speed, and hydrodynamics, play a noteworthy part in bit choice. These variables impact the bit's cutting mechanics and in general execution. It's fundamental to select a bit that can withstand the arranged operational conditions whereas conveying ideal entrance rates. Counseling with bit producers or experienced penetrating engineers can give important bits of knowledge into coordinating bit details with particular operational parameters.

Economic Considerations

While starting bit fetched is a figure, it's significant to assess the add up to fetched per foot penetrated. This comprehensive approach considers components such as bit life, entrance rates, and potential diminishment in trip time. Now and then, contributing to a higher-quality, more costly bit can lead to noteworthy fetched reserve funds over the course of a penetrating extend by moving forward by and large proficiency and decreasing downtime.

By carefully considering these factors, drilling professionals can make informed decisions when selecting diamond drill bits, ensuring optimal performance and cost-effectiveness in their oil rig operations.

Conclusion

Understanding the center components of Diamond Drill Bits for Oil Rigs is fundamental for making educated choices in penetrating operations. From the cutting-edge precious stone framework to the vital liquid channels and the variables affecting bit choice, each component plays a crucial part in accomplishing penetrating victory. As innovation proceeds to development, so too do the capabilities and proficiency of these crucial tools.

Are you looking to optimize your penetrating operations with high-performance precious stone bore bits? Shaanxi Hainaisen Petroleum Innovation Co., Ltd. specializes in creating and fabricating cutting-edge jewel penetrate bits custom fitted to your particular needs. Our broad involvement in oil and gas extraction, coal mining, and geographical studying permits us to give specialized arrangements that upgrade your boring effectiveness and decrease general costs. With our state-of-the-art 3,500 m² office and devoted R&D group, we're prepared to meet the interesting challenges of your boring ventures. Do not settle for imperfect performance—contact us nowadays at postmaster@hnsdrillbit.com to investigate how our customized precious stone bore bits can revolutionize your operations.

References

1. Smith, J. (2022). Advanced Diamond Drill Bit Technologies for Oil and Gas Exploration. Journal of Petroleum Engineering, 45(3), 215-230.

2. Johnson, R., & Williams, T. (2021). Optimizing Fluid Channel Design in Diamond Drill Bits: A Computational Fluid Dynamics Approach. SPE Drilling & Completion, 36(2), 180-195.

3. Brown, A. (2023). Material Innovations in Diamond Drill Bit Matrix Composition. International Journal of Mining Science and Technology, 33(1), 45-60.

4. Lee, S., & Garcia, M. (2022). Economic Analysis of Diamond Drill Bit Selection in Challenging Formations. SPE Economics & Management, 14(3), 220-235.

5. Thompson, K. (2021). The Evolution of Diamond Drill Bit Design for Oil and Gas Applications. Offshore Technology Conference Proceedings, OTC-31092-MS.

6. Wilson, E. (2023). Advancements in Synthetic Diamond Technology for Drilling Applications. Materials Science and Engineering: B, 278, 115659.