Anatomy of Rock Roller Bits: Key Components Explained

Understanding the life structures of a shake roller penetrate bit is significant for increasing in value its usefulness in difficult arrangements. These bits are wonders of designing, composed of a few key components working in concordance to accomplish ideal boring performance.

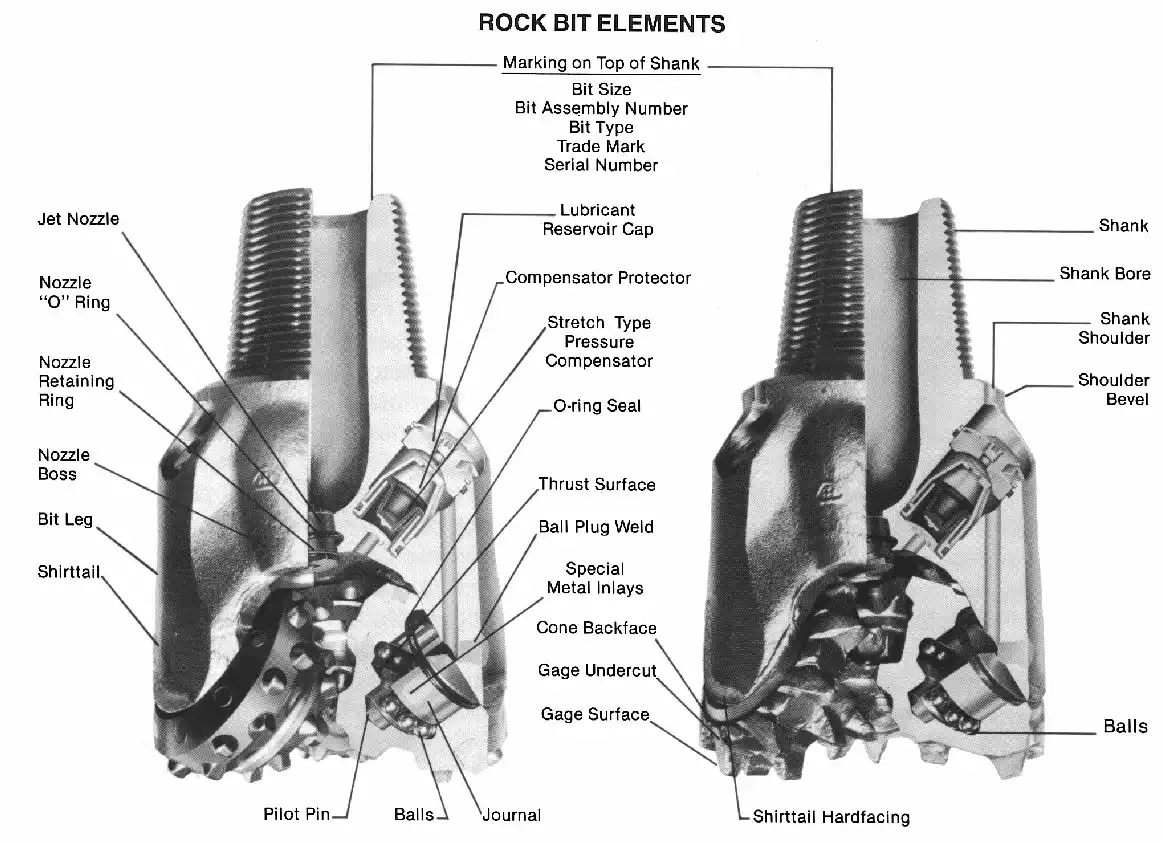

Bit Body

The bit body serves as the establishment of the shake roller bore bit. Regularly created from high-strength steel, it gives the auxiliary astuteness essential to withstand the extraordinary strengths experienced amid boring operations. The body houses the other components and encourages the association to the penetrate string.

Cones or Rollers

Perhaps the most distinctive feature of a rock roller drill bit is its cones or rollers. These conical structures are mounted on the bit body and rotate independently as the bit turns. The number of cones can vary, with tricone bits being a common configuration. Each cone is precisely engineered to optimize cutting action based on the expected formation characteristics.

Cutting Elements

The cutting elements are the workhorses of the bit, directly responsible for breaking the rock. They come in two main types:

- Tungsten Carbide Inserts (TCI): These are small, cylindrical pieces of extremely hard tungsten carbide material pressed into holes drilled in the cone surface. TCI bits are particularly effective in medium to hard formations.

- Steel Teeth: Some bits feature steel teeth that are milled directly into the cone surface. These are often used in softer formations but can be heat-treated for improved durability in harder rocks.

Bearings and Seals

The orientation permit the cones to turn easily around their tomahawks. High-quality heading are significant for keeping up bit execution and life span. Seals ensure the orientation from defilement by penetrating liquids and shake cuttings, which is fundamental for dragging out the bit's operational life.

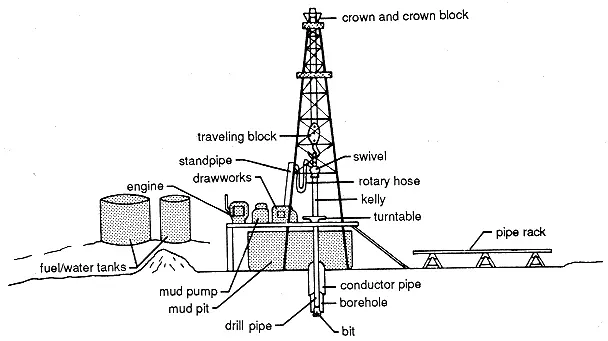

Nozzles

Nozzles are deliberately set openings in the bit body that coordinate penetrating liquid (mud) to cool and grease up the bit whereas moreover making a difference to evacuate cuttings from the foot of the gap. The measure and situation of these spouts are carefully calculated to optimize pressure driven performance.

Shirttail

The shirttail is the external edge of the cone that amplifies towards the bit body. It plays a vital part in securing the heading and seals from harm caused by the borehole divider and cuttings.

Crushing vs. Chipping: Rock Roller Bit Mechanisms

The adequacy of a shake roller penetrate bit in difficult arrangements stems from its capacity to utilize both pulverizing and chipping components. Understanding these forms is key to increasing in value the bit's productivity and selecting the right bit for particular geographical conditions.

Crushing Mechanism

In hard formations, the crushing mechanism is the primary mode of rock destruction employed by rock roller drill bits. As the bit rotates and applies weight, the tungsten carbide inserts or steel teeth impact the rock surface with tremendous force. This impact creates localized stress concentrations that exceed the compressive strength of the rock, causing it to fracture and crumble.

The crushing action is particularly effective in brittle rocks, where the stress waves generated by the impact propagate through the material, creating networks of microfractures. These fractures weaken the rock structure, making it easier for subsequent impacts to further break down the formation.

Chipping Mechanism

While smashing is the overwhelming instrument in difficult arrangements, chipping moreover plays a significant part in the boring prepare. As the cones roll over the foot of the gap, the cutting components rub and gouge the shake surface. This activity actuates pliable stresses in the shake, which most arrangements are less safe to than compressive stresses.

The chipping component is especially viable at expelling as of now broken or debilitated shake, clearing the way for new impacts on the intaglio arrangement. It moreover makes a difference in forming the borehole and keeping up gage diameter.

Synergy Between Crushing and Chipping

The true power of a rock roller drill bit lies in the synergy between crushing and chipping mechanisms. As the bit rotates:

- The crushing action creates initial fractures and weakens the rock structure.

- The rolling motion of the cones causes chipping, removing the weakened material.

- This removal exposes fresh rock surfaces for subsequent crushing impacts.

- The cycle continues, progressively deepening the borehole.

This combined action allows the bit to maintain high rates of penetration even in the hardest formations, while also promoting efficient removal of cuttings from the bottom of the hole.

Hydraulic Assistance

The adequacy of both pulverizing and chipping instruments is improved by the pressure driven activity of the boring liquid. The spouts in the bit body coordinate high-pressure liquid planes to:

- Clean the cutting elements, preventing bit balling (accumulation of cuttings on the bit face).

- Cool the bit components, prolonging their operational life.

- Aid in the removal of cuttings, preventing regrinding of already broken rock.

- In some cases, assist in rock breaking through erosive action or by exploiting existing fractures.

By understanding these mechanisms, drilling engineers can optimize bit selection and operating parameters to achieve maximum efficiency in hard formation drilling operations.

Optimizing Drilling: Matching Bit Type to Formation Hardness

Selecting the right rock roller drill bit for a given formation is crucial for optimizing drilling performance, reducing costs, and ensuring the success of drilling operations. The hardness and abrasiveness of the formation play a significant role in determining the most suitable bit design.

Formation Hardness Classification

Geological formations are typically classified into soft, medium, and hard categories based on their compressive strength and drillability. However, a more nuanced approach is often necessary for precise bit selection:

- Soft formations: < 5,000 psi compressive strength

- Medium-soft formations: 5,000 - 10,000 psi

- Medium-hard formations: 10,000 - 15,000 psi

- Hard formations: 15,000 - 30,000 psi

- Extremely hard formations: > 30,000 psi

Bit Selection Criteria

When matching a rock roller drill bit to formation hardness, several factors must be considered:

- Cutting Structure: The type, size, and arrangement of cutting elements (tungsten carbide inserts or steel teeth) should be tailored to the formation hardness.

- IADC Code: The International Association of Drilling Contractors (IADC) classification system provides a standardized method for describing bit characteristics and their suitability for different formations.

- Cone Offset: The degree of offset (the angle between the cone axis and the bit centerline) affects the scraping action and should be adjusted based on formation hardness.

- Hydraulics: Nozzle configuration and sizing must be optimized to ensure proper cleaning and cooling in the specific formation.

Bit Types for Different Formation Hardness

Here's a general guide for selecting rock roller drill bits based on formation hardness:

Soft to Medium-Soft Formations

- Steel tooth bits with long, widely spaced teeth

- Higher cone offset for increased scraping action

- Larger nozzles to handle higher flow rates and prevent bit balling

Medium to Medium-Hard Formations

- Tungsten carbide insert (TCI) bits with chisel-shaped inserts

- Moderate cone offset

- Balanced hydraulics for effective cleaning and cooling

Hard to Extremely Hard Formations

- TCI bits with compact, closely spaced inserts

- Minimal cone offset to focus on crushing action

- Smaller nozzles for increased jet velocity to aid in rock breaking

Advanced Bit Designs

Modern rock roller drill bits often incorporate advanced features to enhance performance across a range of formation hardnesses:

- Dual-Row TCI Bits: Combining two rows of inserts with different shapes to handle interbedded formations

- Enhanced Inserts: Specially shaped or treated inserts for improved wear resistance and cutting efficiency

- Optimized Cone Geometry: Designed to maximize bottom hole coverage and minimize tracking

- Advanced Sealing Systems: To prolong bit life in abrasive environments

The Importance of Proper Bit Selection

Choosing the right rock roller drill bit for the formation hardness can lead to:

- Increased rate of penetration (ROP)

- Extended bit life

- Improved borehole quality

- Reduced overall drilling costs

However, it's imperative to note that arrangement hardness can shift inside a single well, and startling changes may require bit changes or alterations to penetrating parameters. Ceaseless observing and investigation of boring information are basic for keeping up ideal execution all through the operation.

Conclusion

Rock Roller Drill Bit are irreplaceable apparatuses in the boring industry, competent of handling the hardest arrangements with exceptional effectiveness. Their victory lies in the perplexing plan that combines strong development with progressed cutting instruments. By understanding the life systems of these bits, the interaction between smashing and chipping activities, and the significance of coordinating bit sort to arrangement hardness, boring experts can altogether improve their operations.

For oil and gas companies, coal mining operations, and water well penetrating groups looking to optimize their boring execution, selecting the right shake roller bore bit is significant. At Shaanxi Hainaisen Petroleum Innovation Co., Ltd., we specialize in giving high-quality bore bits and coordinates specialized arrangements custom fitted to your particular needs. Our broad extend of items, counting the flexible 140mm 3-blade roller bit, is designed to exceed expectations in different shake arrangements, guaranteeing reliable comes about and cost-effective operations.

Whether you're managing with delicate sedimentary layers or the hardest molten rocks, our group of specialists is prepared to help you in choosing the culminate bit for your venture. With our progressed fabricating offices and committed R&D group, we're committed to conveying inventive penetrating arrangements that drive your success.

To learn more approximately how our shake roller bore bits can revolutionize your boring operations, if you don't mind contact us at hainaisen@hnsdrillbit.com. Let's work together to lift your boring productivity and handle indeed the most challenging arrangements with certainty.

References

1. Smith, J.R. and Brown, T.L. (2018). "Advanced Rock Roller Bit Designs for Hard Formation Drilling." Journal of Petroleum Technology, 70(5), 62-68.

2. Johnson, A.K. et al. (2019). "Optimizing Drill Bit Selection in Variable Hardness Formations." SPE Drilling & Completion, 34(2), 145-157.

3. Williams, S.M. and Davis, R.E. (2020). "Comparative Analysis of Crushing and Chipping Mechanisms in Rock Roller Bits." International Journal of Rock Mechanics and Mining Sciences, 128, 104244.

4. Chen, X. and Li, Y. (2021). "Influence of Formation Hardness on Rock Roller Bit Performance: A Numerical Study." Journal of Petroleum Science and Engineering, 196, 108031.

5. Thompson, G.H. (2017). "Rock Bit Hydraulics: Maximizing Efficiency in Hard Formation Drilling." SPE Annual Technical Conference and Exhibition, San Antonio, Texas, USA, October 9-11.

6. Rodriguez, M.C. and Patel, A. (2022). "Advancements in Tungsten Carbide Insert Technology for Extreme Hardness Drilling." Offshore Technology Conference, Houston, Texas, USA, May 2-5.