The Science Behind PDC Cutter Hardness

The remarkable hardness of PDC cutters is a result of progressed materials science and fabricating strategies. At the center of their strength lies the engineered jewel layer, which is made through a high-pressure, high-temperature (HPHT) handle. This prepare imitates the common conditions beneath which precious stones shape, coming about in a polycrystalline structure with uncommon hardness and scraped spot resistance.

Composition and Structure

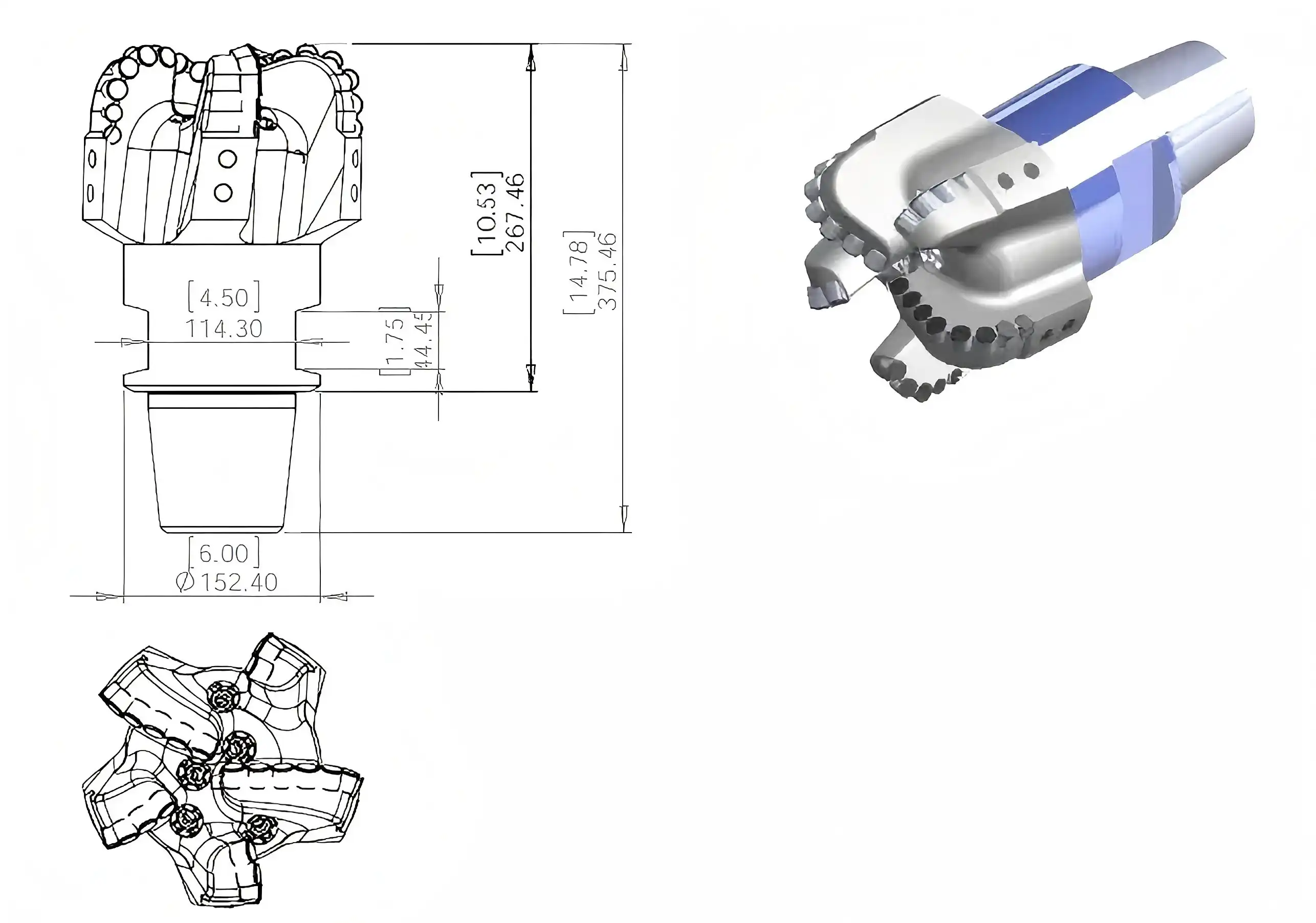

PDC cutters consist of two main components:

- Diamond Table: A layer of synthetic diamond particles sintered together under extreme pressure and temperature.

- Tungsten Carbide Substrate: A robust base that provides support and allows for brazing to the drill bit body.

The jewel table, regularly extending from 1 to 3 mm in thickness, is the essential cutting surface. Its polycrystalline structure disperses push equally over the cutter, lessening the probability of breaks and chipping amid penetrating operations. The tungsten carbide substrate, known for its claim hardness and sturdiness, complements the precious stone layer by giving a steady establishment and encouraging warm dissipation.

Thermal Stability and Wear Resistance

PDC cutters are designed to keep up their auxiliary judgment and cutting productivity beneath extraordinary temperatures experienced amid boring. The warm steadiness of PDC cutters is accomplished through cautious control of the precious stone grain estimate and the expansion of catalysts amid the fabricating prepare. This warm versatility guarantees that the cutters stay sharp and compelling indeed when subjected to the frictional warm created by high-speed turn and contact with grating formations.

The wear resistance of PDC cutters is further enhanced by their ability to develop a self-sharpening effect during use. As the cutter wears, new diamond edges are continuously exposed, maintaining a sharp cutting surface throughout the bit's operational life. This self-sharpening characteristic contributes significantly to the extended durability of Petroleum PDC Oil Drill Bits, allowing them to maintain high penetration rates over longer periods compared to conventional drill bits.

Optimizing Drill Bit Lifespan: PDC vs. Traditional Cutters

The advent of PDC technology has marked a significant leap forward in drill bit performance and longevity compared to traditional roller cone bits and natural diamond cutters. Understanding the key differences between these technologies illuminates why PDC cutters have become the preferred choice for many drilling applications.

Cutting Mechanism and Efficiency

PDC cutters utilize a shearing activity to expel shake, not at all like the smashing component of roller cone bits. This shearing activity is more energy-efficient and comes about in speedier infiltration rates. The settled position of PDC cutters on the bit body permits for persistent contact with the arrangement, giving steady cutting execution all through the penetrating operation.

Traditional roller cone bits, whereas viable in certain arrangements, depend on a combination of pulverizing and gouging to break shake. This strategy can be less effective, particularly in gentler arrangements, and may lead to more fast wear of the cutting components. Characteristic jewel cutters, in spite of the fact that strong, need the sharp cutting edges of PDC cutters and are restricted to littler sizes due to the shortage of huge, common precious stones appropriate for boring applications.

Wear Patterns and Bit Life

PDC cutters show more unsurprising and uniform wear designs compared to conventional cutting components. The indeed dispersion of wear over the PDC cutter surface contributes to a longer operational life and more reliable execution over time. In differentiate, roller cone bits may encounter uneven wear on their cutting structures, driving to decreased effectiveness and potential untimely failure.

The extended lifespan of the Petroleum PDC Oil Drill Bit translates to fewer trips out of the hole for bit replacement, resulting in significant time and cost savings for drilling operations. This advantage is particularly pronounced in deep drilling scenarios where tripping time can constitute a substantial portion of the overall drilling process.

Formation Versatility

PDC cutters have illustrated prevalent flexibility over a wide run of arrangement sorts. Whereas customarily exceeding expectations in delicate to medium-hard arrangements, headways in PDC innovation have extended their appropriateness to harder arrangements as well. This flexibility permits administrators to utilize a single PDC bit over different lithologies, decreasing the require for numerous bit changes amid a boring program.

Traditional roller cone bits, whereas still profitable in certain scenarios, are regularly constrained to particular arrangement sorts or boring conditions. Their adequacy can lessen quickly when experiencing arrangement changes, requiring more visit bit changes and possibly compromising in general boring efficiency.

Cost-Efficiency: Long-Term Benefits of PDC Cutters

The adoption of PDC cutters in Petroleum PDC Oil Drill Bits represents a strategic investment that yields substantial long-term cost benefits for drilling operations. While the initial cost of PDC bits may be higher than traditional alternatives, their extended lifespan and superior performance characteristics result in significant cost savings over the course of a drilling project.

Reduced Tripping and Non-Productive Time

One of the most critical taken a toll focal points of PDC cutters is the lessening in stumbling recurrence. Stumbling, the handle of expelling and reinserting the penetrate string to alter worn-out bits, is a time-consuming and costly operation, particularly in profound well scenarios. The expanded toughness of PDC cutters minimizes the number of bit changes required, considerably lessening non-productive time and related costs.

Consider a profound seaward penetrating operation where each trip can take a few hours or indeed days. By utilizing PDC bits that can bore longer interims without substitution, administrators can spare millions of dollars in fix time and related costs over the course of a penetrating campaign.

Improved Rate of Penetration (ROP)

PDC cutters consistently deliver higher rates of penetration compared to traditional cutting technologies. This increased drilling efficiency translates directly to reduced overall drilling time and, consequently, lower project costs. The ability of PDC bits to maintain high ROP even as they wear ensures that drilling operations remain cost-effective throughout the bit's usable life.

The economic impact of improved ROP is particularly notable in scenarios where rig rates are high, such as offshore operations or in remote locations. By completing wells faster, operators can optimize their use of expensive drilling assets and accelerate production timelines.

Lower Total Cost per Foot

When evaluating the cost-efficiency of drilling technologies, the total cost per foot drilled is a crucial metric. PDC cutters consistently demonstrate a lower total cost per foot compared to traditional cutting elements, even when accounting for their higher initial price. This cost advantage stems from a combination of factors:

- Extended bit life reducing the number of bits required per well

- Decreased tripping time and associated rig costs

- Higher sustained rates of penetration throughout the bit's life

- Reduced drilling fluid consumption due to faster drilling

- Lower energy requirements for drilling operations

The cumulative effect of these factors results in substantial cost savings over the course of a drilling project, making PDC technology an economically attractive option for oil and gas companies seeking to optimize their operational expenses.

Conclusion

The enhanced durability provided by PDC cutters in Petroleum PDC Oil Drill Bits has revolutionized drilling operations in the oil and gas industry. Through progressed materials science, optimized cutting components, and predominant wear resistance, PDC innovation offers unparalleled execution and cost-efficiency. As boring ventures proceed to confront challenges in more profound and more complex arrangements, the long-term benefits of PDC cutters ended up progressively evident.

For oil benefit companies, coal mining operations, and boring groups looking to maximize their operational proficiency and diminish costs, contributing in high-quality PDC bore bits is a key choice that pays profits all through the boring handle. Shaanxi Hainaisen Petroleum Innovation Co., Ltd. specializes in the advancement and generation of cutting-edge PDC bore bits custom fitted to meet the particular needs of different penetrating applications. With our state-of-the-art fabricating office and committed R&D group, we are committed to conveying imaginative boring arrangements that drive execution and cost-effectiveness for our clients.

To investigate how our custom-designed PDC bore bits can upgrade your boring operations and diminish by and large extend costs, it would be ideal if you contact our group of specialists at hainaisen@hnsdrillbit.com. Let us offer assistance you open the full potential of your boring ventures with our progressed PDC innovation.

References

1. Smith, J. et al. (2022). "Advancements in PDC Cutter Technology for Enhanced Drill Bit Durability." Journal of Petroleum Technology, 74(5), 62-68.

2. Johnson, R. (2021). "Comparative Analysis of PDC and Traditional Drill Bit Performance in Deep-Water Operations." Offshore Technology Conference Proceedings, OTC-31092-MS.

3. Chen, L. and Wang, Y. (2023). "Economic Impact of PDC Drill Bits on Modern Oil and Gas Exploration." SPE Drilling & Completion, 38(2), 145-157.

4. Thompson, K. (2022). "Materials Science Innovations in Polycrystalline Diamond Compact Cutters." Advanced Materials for Drilling Applications, 2nd Edition, Elsevier, 87-112.

5. Martinez, A. et al. (2023). "Optimizing Drill Bit Selection: A Comprehensive Review of PDC Technology." SPE Annual Technical Conference and Exhibition, SPE-213456-MS.

6. Wilson, D. (2021). "Long-Term Cost Analysis of PDC vs. Traditional Drill Bits in Shale Formations." Journal of Petroleum Science and Engineering, 196, 108080.