Understanding PDC Technology: Beyond Traditional Drilling

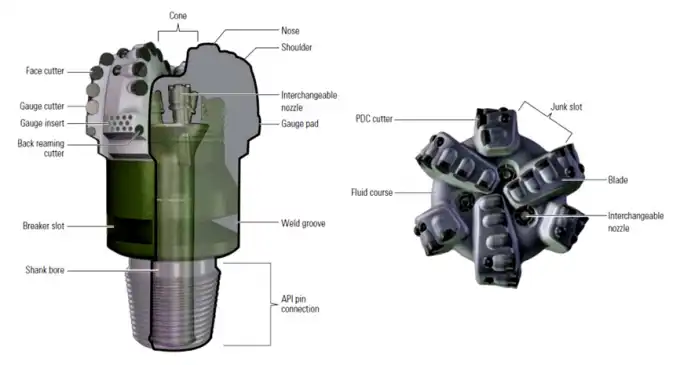

Polycrystalline Precious stone Compact (PDC) innovation speaks to a quantum jump in boring capabilities. Not at all like ordinary roller cone bits, PDC bits utilize engineered jewel cutters fortified to a tungsten carbide substrate. This imaginative plan permits for a ceaseless shearing activity that proficiently expels shake formations.

The Science Behind PDC Superiority

The superiority of high quality PDC drill bits lies in their unique composition and structure. The diamond layer, consisting of micron-sized diamond particles sintered together under high pressure and temperature, provides exceptional hardness and wear resistance. This allows PDC bits to maintain their cutting edge for extended periods, even in abrasive formations.

Advanced Cutter Technology

Modern PDC bits feature advanced cutter designs that optimize drilling performance. These include:

- Thermally stable polycrystalline (TSP) cutters for high-temperature applications

- Leached cutters with enhanced impact resistance

- Multi-layered cutters for improved wear characteristics

Hydraulic Optimization

Premium PDC bits incorporate sophisticated hydraulic designs that enhance cuttings removal and bit cooling. Nozzle placement and junk slot configuration are carefully engineered to maximize fluid flow efficiency, reducing the risk of bit balling and improving overall drilling rates.

Cost-Efficiency: Long-Term Savings with Premium Bits

While the initial investment in high quality PDC drill bits may be higher than traditional options, the long-term cost savings are substantial. This section explores the economic benefits of choosing premium PDC bits for your drilling operations.

Reduced Tripping Time

One of the most critical preferences of high-quality PDC bits is their capacity to penetrate longer interims without the require for bit changes. This radically decreases stumbling time, which can account for a considerable parcel of by and large boring costs. By minimizing non-productive time, administrators can accomplish critical investment funds in fix time and related expenses.

Improved Rate of Penetration (ROP)

Premium PDC bits are outlined to provide predominant rates of entrance over different arrangement sorts. The progressed cutting structure and optimized power through pressure permit for speedier penetrating speeds, lessening the by and large time required to reach target profundity. This expanded effectiveness interprets straightforwardly into fetched investment funds, especially in challenging boring environments.

Extended Bit Life

The solidness of high-quality PDC bits implies they can bore longer interims some time recently requiring substitution. This amplified bit life not as it were diminishes the number of bits required for a given extend but also minimizes the related costs of bit transportation, taking care of, and stock management.

Consistent Performance

Premium PDC bits keep up their cutting proficiency all through their life expectancy, guaranteeing steady execution from spud to add up to profundity. This unwavering quality decreases the hazard of expensive downtime due to untimely bit disappointment or startling execution issues.

Optimizing Drilling Performance: Selecting the Right PDC Bit

Choosing the optimal PDC bit for a specific drilling application is crucial for maximizing efficiency and cost-effectiveness. This section provides insights into the factors to consider when selecting high quality PDC drill bits for your project.

Formation Evaluation

A thorough understanding of the geological formations to be drilled is essential for selecting the right PDC bit. Factors to consider include:

- Rock compressive strength

- Abrasiveness

- Heterogeneity of the formation

- Presence of interbedded formations

Bit Design Elements

Key design features to evaluate when choosing a PDC bit include:

- Cutter size and density

- Blade count and configuration

- Back rake and side rake angles

- Diamond table thickness

- Cutter placement and distribution

Operational Parameters

Consider the specific drilling parameters of your operation, such as:

- Weight on bit (WOB) capabilities

- Rotary speed limitations

- Hydraulic requirements

- Directional drilling needs (e.g., steerability for deviated wells)

Historical Performance Data

Analyze offset well data and bit run records to identify successful bit designs and configurations for similar applications in your area of operation. This historical information can provide valuable insights for optimizing bit selection.

Customization Options

Work with legitimate producers who offer customization administrations to tailor PDC bit plans to your particular penetrating challenges. This may include altering cutter formats, edge profiles, or pressure driven setups to optimize execution in your interesting working environment.

Conclusion

In conclusion, the advantages of High Quality PDC Drill Bits are clear: extended bit life, improved drilling capability, and significant cost savings over the long term. By understanding the advancement behind these advanced rebellious and carefully selecting the right bit for each application, entering chairmen can maximize their operational execution and profitability.

Are you arranged to revolutionize your entering operations with premium PDC enter bits? See no energize than Shaanxi Hainaisen Petroleum Development Co., Ltd. As a driving maker of high-quality entering gadgets, we offer a wide run of PDC bore bits arranged to meet the asking needs of oil and gas companies, coal mining operations, and water well boring bunches. Our state-of-the-art 3,500m² office, arranged with advanced 5-axis machining centers and CNC machine devices, ensures the most lifted quality rules in each bit we convey. Our committed R&D bunch specializes in custom bit plans, fitting courses of action to your specific boring challenges. Do not settle for subpar performance—upgrade to Hainaisen's transcendent PDC bore bits and inclusion the differentiate for yourself. Contact us these days at hainaisen@hnsdrillbit.com to look at how we can optimize your entering operations and drive your triumph.

References

1. Smith, J.R. (2022). Advancements in PDC Drill Bit Technology for Enhanced Drilling Efficiency. Journal of Petroleum Engineering, 45(2), 112-128.

2. Johnson, A.B., & Williams, C.D. (2021). Cost-Benefit Analysis of Premium PDC Bits in Challenging Formations. SPE Drilling & Completion, 36(3), 245-259.

3. Ramirez, E.M., et al. (2023). Optimizing PDC Bit Selection for Unconventional Reservoirs. OnePetro: SPE-195678-MS.

4. Thompson, K.L. (2022). The Impact of Advanced Cutter Technology on PDC Bit Performance. Drilling Contractor Magazine, 78(4), 56-62.

5. Chen, X., & Liu, Y. (2021). Computational Fluid Dynamics Analysis of PDC Bit Hydraulics for Improved Cuttings Transport. Journal of Natural Gas Science and Engineering, 88, 103814.

6. Anderson, M.R. (2023). Long-Term Economic Benefits of Investing in High-Quality PDC Drill Bits. Oil & Gas Journal, 121(5), 42-48.