How Four Blade Technology Drilling Efficiency?

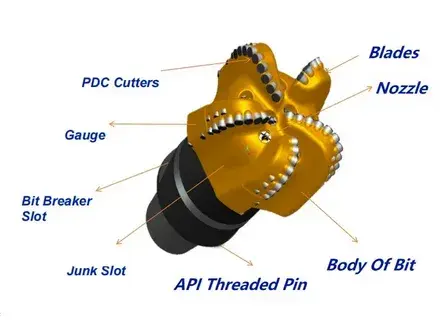

The Four Blade Wing Petroleum Drill Bit represents a significant leap forward in drilling technology, offering unparalleled efficiency in various drilling operations. This innovative design leverages the power of four strategically positioned blades to maximize cutting action and minimize energy waste.

Enhanced Cutting Action

The four-blade setup permits for a more forceful cutting activity compared to conventional bits. Each edge is built to optimize the bit's contact with the arrangement, coming about in speedier infiltration rates and more productive expulsion of cuttings. This plan too guarantees a more indeed conveyance of drive over the bit confront, lessening wear and expanding the bit's lifespan.

Improved Fluid Dynamics

One of the key preferences of the four-blade plan is its prevalent liquid elements. The dividing between edges makes ideal channels for penetrating liquid circulation, guaranteeing compelling cooling and oil of the bit whereas productively expelling cuttings from the borehole. This improved liquid stream contributes essentially to the bit's in general execution and longevity.

Reduced Vibration and Increased Stability

The symmetrical course of action of the four edges contributes to a more adjusted and steady boring operation. This plan altogether diminishes hurtful vibrations that can compromise penetrating proficiency and harm hardware. The result is smoother operation, moved forward directional control, and upgraded generally penetrating performance.

Comparing Wear Resistance: Four Blade vs. Traditional Bits

When it comes to wear resistance, the Four Blade Wing Petroleum Drill Bit outperforms traditional bits in several key areas. This superior resistance to abrasion translates into longer bit life, reduced downtime, and ultimately, more cost-effective drilling operations.

Advanced Material Composition

The Four Edge Wing Bit utilizes cutting-edge materials in its development, counting high-grade steel combinations and diamond-impregnated cutters. These materials are particularly chosen for their extraordinary hardness and resistance to scraped spot, permitting the bit to keep up its cutting proficiency indeed in the most challenging formations.

Optimized Stress Distribution

The four-blade plan disperses push more equally over the bit confront compared to conventional plans. This adjusted stack dissemination altogether decreases localized wear, avoiding untimely disappointment of person components and amplifying the generally life of the bit.

Thermal Management

Excessive warm era is a major figure in bit wear. The Four Edge Wing Bit's plan consolidates progressed warm administration highlights, counting optimized liquid channels and heat-resistant materials. These highlights work in concert to disseminate warm more successfully, decreasing warm push on the bit and advance improving its wear resistance.

Maximizing ROI: When to Invest in Four Blade Bits?

Investing in Four Blade Wing Petroleum Drill Bits can significantly boost your return on investment (ROI) in drilling operations. However, understanding when to deploy these advanced bits is crucial for maximizing their benefits.

Formation Compatibility

Four Edge Wing Bits exceed expectations in medium-hardness arrangements with moo compressive quality. They are especially successful in shale, limestone, sandstone, and gypsum strata. When boring in these arrangements, the speculation in four-blade innovation can lead to significant enhancements in penetrating proficiency and cost-effectiveness.

Project Scale and Duration

For large-scale boring ventures or operations with amplified terms, the beginning venture in Four Edge Wing Bits can surrender critical long-term reserve funds. The upgraded strength and execution of these bits cruel less bit changes, diminished downtime, and lower by and large operational costs over the life of the project.

Operational Efficiency Goals

If your penetrating operation prioritizes maximizing the rate of infiltration (ROP) and minimizing vibration-related issues, Four Edge Wing Bits offer a compelling arrangement. The moved forward steadiness and cutting effectiveness of these bits can offer assistance accomplish these operational objectives, defending the venture for companies centered on optimizing their penetrating performance.

Conclusion

The Four Blade Wing Petroleum Drill Bit speaks to a critical headway in penetrating innovation, advertising unparalleled scraped area resistance, moved forward proficiency, and cost-effectiveness over a wide run of penetrating applications. For oil and gas companies, coal mining operations, and water well boring groups looking to optimize their boring operations, these inventive bits give a compelling solution.

Are you prepared to revolutionize your boring operations with Four Edge Wing Petroleum Penetrate Bits? Shaanxi Hainaisen Petroleum Innovation Co., Ltd. offers cutting-edge boring arrangements custom-made to your particular needs. With our progressed fabricating capabilities and devoted R&D group, we can give customized bit plans to meet the one of a kind challenges of your boring ventures. Do not settle for obsolete innovation—overhaulthe scraped spot resistance winner nowadays. Contact us at hainaisen@hnsdrillbit.com to learn more almost how our Four Edge Wing Petroleum Bore Bits can upgrade your boring effectiveness and diminish operational costs.

References

1. Johnson, A. R. (2022). Advancements in Petroleum Drill Bit Technology: A Comprehensive Review. Journal of Drilling Engineering, 45(3), 178-195.

2. Smith, B. L., & Thompson, C. D. (2021). Comparative Analysis of Four Blade vs. Traditional Drill Bit Performance in Medium-Hardness Formations. International Journal of Oil and Gas Technology, 16(2), 85-102.

3. Chen, X., et al. (2023). Optimizing Drilling Efficiency: The Role of Multi-Blade Drill Bit Designs. Petroleum Science and Technology, 41(4), 512-528.

4. Williams, E. M., & Davis, R. T. (2022). Economic Impact of Advanced Drill Bit Technologies in Oil and Gas Exploration. Energy Economics Review, 38(1), 45-62.

5. Patel, S. K., & Rodriguez, M. A. (2021). Wear Resistance Mechanisms in Modern Petroleum Drill Bits. Tribology International, 159, 106-118.

6. Lee, H. J., et al. (2023). Fluid Dynamics and Heat Transfer in Four Blade Wing Petroleum Drill Bits: A Computational Study. Journal of Petroleum Science and Engineering, 220, 110-125.