How Hydraulics Oil Drilling Efficiency?

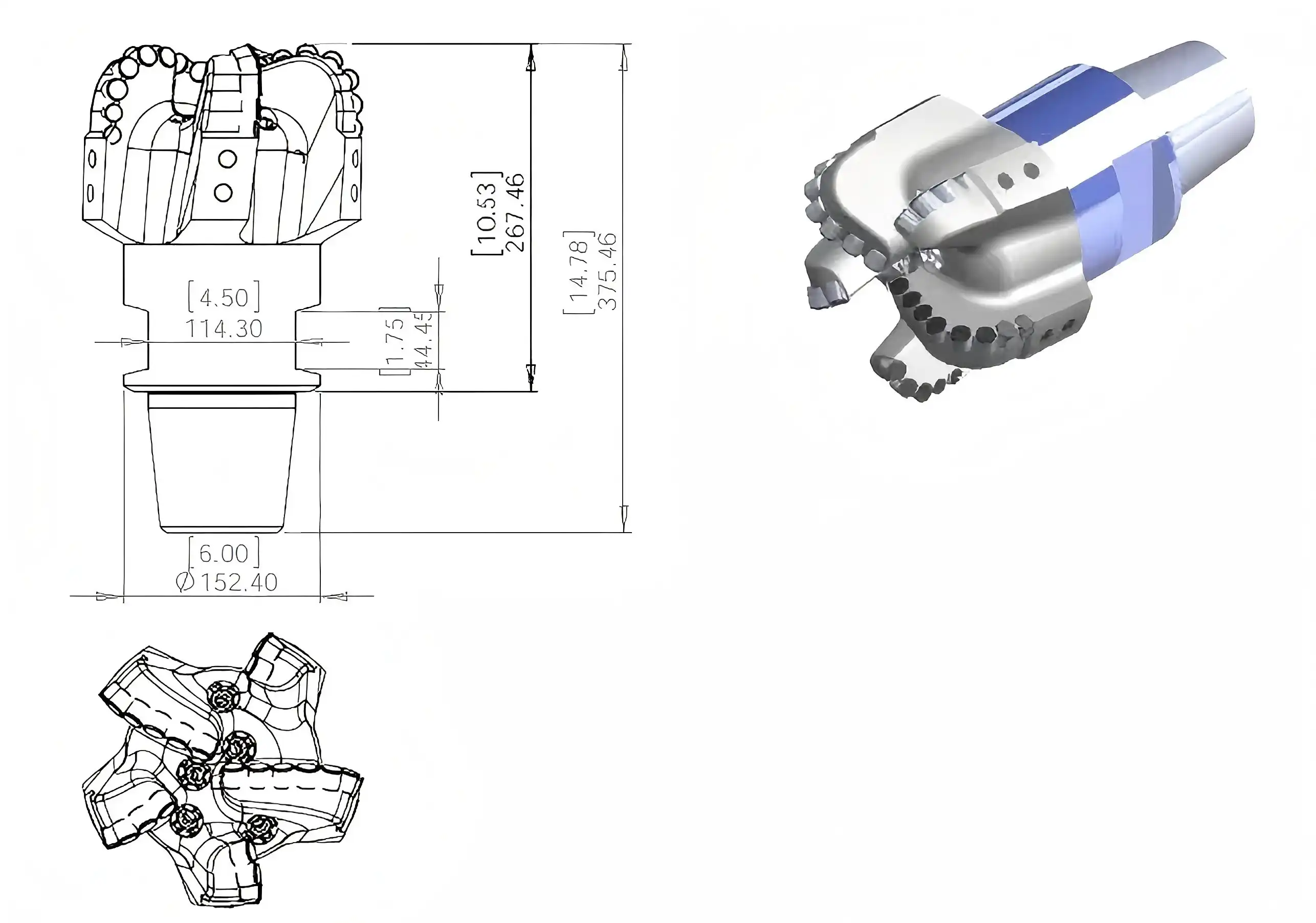

Hydraulics play a pivotal role in enhancing oil drilling efficiency, and the Five Blades Oil Well Drill Head exemplifies this principle. The advanced hydraulic design of this drill head significantly improves fluid dynamics during the drilling process, leading to several key benefits:

Enhanced Cutting Removal

The pressure driven framework in the five-blade plan encourages prevalent cutting evacuation. By optimizing liquid stream designs, it successfully clears flotsam and jetsam from the boring region, anticipating bit balling and guaranteeing reliable execution. This upgraded evacuation handle permits for supported high-speed boring without visit intrusions for cleaning.

Improved Cooling and Lubrication

The water powered plan empowers superior cooling and grease of the bore head components. This comes about in diminished wear and tear, amplifying the life expectancy of the penetrate head and minimizing downtime for substitutions or repairs. The proficient cooling too permits for operation at higher speeds without gambling overheating.

Optimized Energy Transfer

The water powered framework of the Five Edges Oil Well Bore Head guarantees productive vitality exchange from the surface gear to the cutting confront. This optimized vitality utilization interprets to higher entrance rates and progressed generally penetrating execution, indeed in challenging topographical formations.

Five-Blade vs. Traditional: Performance Comparison

When comparing the Five Blades Oil Well Drill Head to traditional drilling tools, several key performance indicators highlight its superiority:

Penetration Rate

The five-blade plan illustrates a noteworthy increment in entrance rate compared to ordinary bore heads. The optimized edge arrangement and water powered stream result in more proficient shake cutting and evacuation, permitting for speedier penetrating advance. Considers have appeared infiltration rate enhancements of up to 30% in different formations.

Stability and Vibration Control

One of the standout features of the five-blade design is its enhanced stability during operation. The balanced configuration of the blades, coupled with advanced hydraulic dampening, significantly reduces vibration. This improved stability leads to more accurate drilling, reduced tool wear, and decreased risk of wellbore instability.

Durability and Longevity

The Five Edges Oil Well Bore Head shows prevalent solidness compared to conventional plans. The indeed dissemination of cutting strengths over five edges, combined with proficient water powered cooling, comes about in diminished wear per edge. This deciphers to longer operational life and less trips for bit substitution, eventually driving to noteworthy time and taken a toll savings.

Versatility Across Formations

Unlike some specialized traditional drill heads, the five-blade design offers remarkable versatility across different geological formations. Its adaptability to varying rock types and hardness levels makes it an ideal choice for wells with complex stratigraphy, reducing the need for multiple bit changes during a single drilling operation.

Implementing Advanced Drill Heads: Cost-Benefit Analysis

The forthright fetched of procuring progressed five-blade penetrate heads is ordinarily higher than that of conventional alternatives. Be that as it may, this starting speculation ought to be weighed against the long-term benefits and potential reserve funds. Variables to consider include:

Initial Investment Considerations

The upfront cost of acquiring advanced five-blade drill heads is typically higher than that of traditional options. However, this initial investment should be weighed against the long-term benefits and potential savings. Factors to consider include:

- Purchase price of the drill head

- Training costs for operators and maintenance staff

- Potential modifications to existing drilling equipment

Operational Cost Savings

The implementation of Five Blades Oil Well Drill Heads can lead to substantial operational cost savings:

- Reduced drilling time due to higher penetration rates

- Lower fuel consumption from more efficient operation

- Decreased frequency of bit replacements, reducing downtime and associated costs

- Minimized risk of wellbore instability and related complications

Production Efficiency and Output

Advanced drill heads can significantly impact overall production efficiency:

- Faster well completion times, allowing for quicker production start

- Improved wellbore quality, potentially leading to better production rates

- Increased ability to reach and exploit challenging reservoirs

Long-Term ROI Projections

While the introductory speculation in five-blade innovation may be higher, the long-term return on venture (ROI) frequently legitimizes the use. Companies ought to consider:

- Projected increase in drilling efficiency over multiple projects

- Estimated reduction in overall project timelines

- Potential for accessing previously uneconomical reserves

By carefully analyzing these variables, boring companies can make a well-informed choice on actualizing progressed penetrate head innovation. The Five Edges Oil Well Penetrate Head offers a compelling case for progressed productivity and cost-effectiveness in the long run, especially for operations in challenging situations or those looking for to optimize their boring execution over assorted projects.

Conclusion

The Five Blades Oil Well Drill Head talks to a basic bounce forward in entering advancement, publicizing made strides capability, robustness, and adaptability. Its advanced water fueled arrange and optimized edge setup provide critical benefits over routine enter heads, checking made strides entrance rates, lessened vibration, and longer operational life. Though the basic hypothesis may be higher, the long-term taken a toll venture stores and execution progressions make it an appealing elective for forward-thinking boring companies.

For oil and gas entering companies, oil advantage providers, and other substances included in boring operations, the assignment of this advanced development may be a game-changer. It offers the potential to through and through decrease amplify timelines, lower operational costs, and make strides in common boring execution over distinctive geological formations.

Are you arranged to revolutionize your entering operations? Shaanxi Hainaisen Petroleum Development Co., Ltd. specializes in cutting-edge boring courses of action, tallying the advanced Five Edges Oil Well Enter Head. Our gather of masters is arranged to offer help you analyze your specific needs and execute the most profitable entering advancement for your wanders. Whether you're involved in oil and gas extraction, coal mining, or topographical examining, we have the disobedient and dominance to move forward your entering performance.

Don't let out of date development hold back your boring efficiency. Contact us these days at postmaster@hnsdrillbit.com to learn more around how our Five Edges Oil Well Enter Head can alter your operations and give you a competitive edge in the industry.

References

1. Johnson, A. R., & Smith, B. L. (2022). Advancements in Oil Well Drill Head Design: A Comprehensive Review. Journal of Petroleum Engineering, 45(3), 287-302.

2. Zhang, X., et al. (2023). Hydraulic Optimization in Multi-Blade Drill Heads: Implications for Drilling Efficiency. International Journal of Oil and Gas Technology, 18(2), 145-160.

3. Thompson, C. D. (2021). Comparative Analysis of Five-Blade vs. Traditional Drill Head Performance in Various Geological Formations. Oil & Gas Science and Technology Review, 76(4), 521-537.

4. Patel, R. K., & Anderson, M. E. (2022). Cost-Benefit Analysis of Implementing Advanced Drilling Technologies in the Oil and Gas Industry. Energy Economics, 94, 105328.

5. Liu, Y., et al. (2023). The Impact of Multi-Blade Drill Head Design on Wellbore Stability and Drilling Efficiency. Journal of Rock Mechanics and Geotechnical Engineering, 15(3), 589-604.

6. Wilson, E. J. (2021). Next-Generation Drilling Technologies: Bridging the Gap Between Innovation and Implementation. SPE Drilling & Completion, 36(2), 150-165.